Crab stick film peeling device

A crab stick and film technology, applied in the field of crab stick film peeling devices, can solve the problems of difficult working conditions, unsafe hidden dangers, low production efficiency, etc., and achieve the effects of guaranteed peeling effect, reduced labor intensity and high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

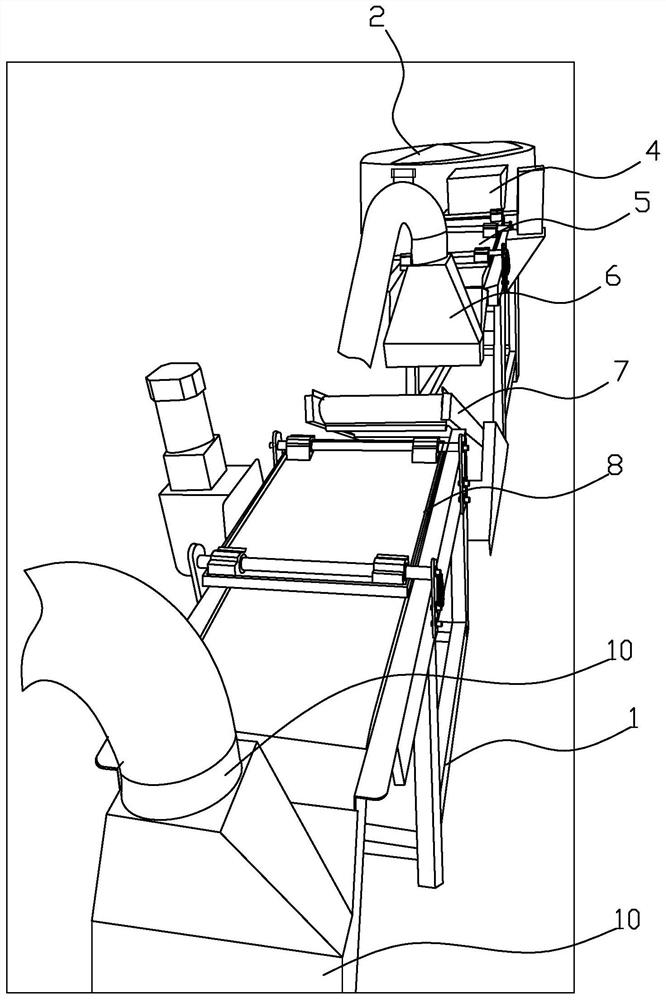

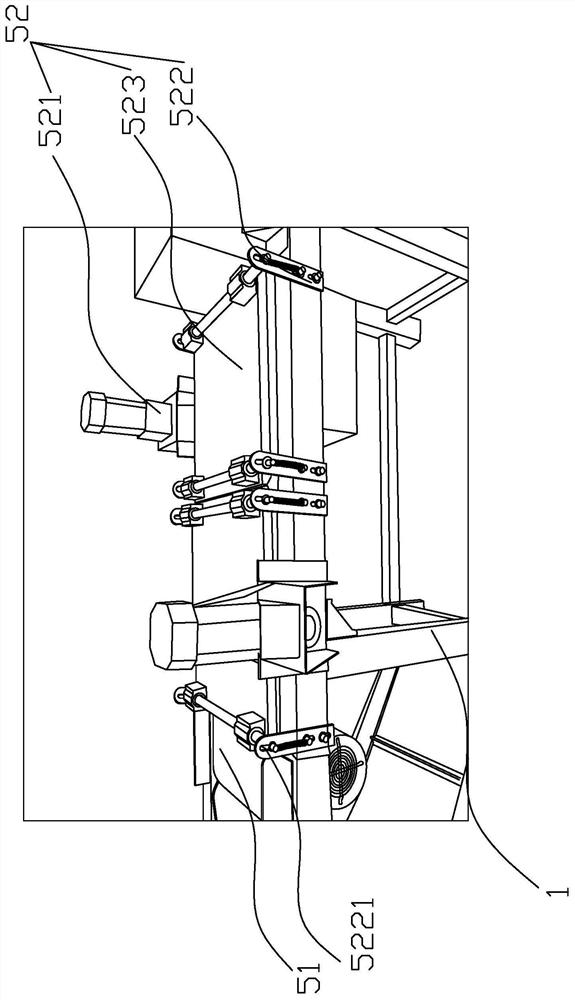

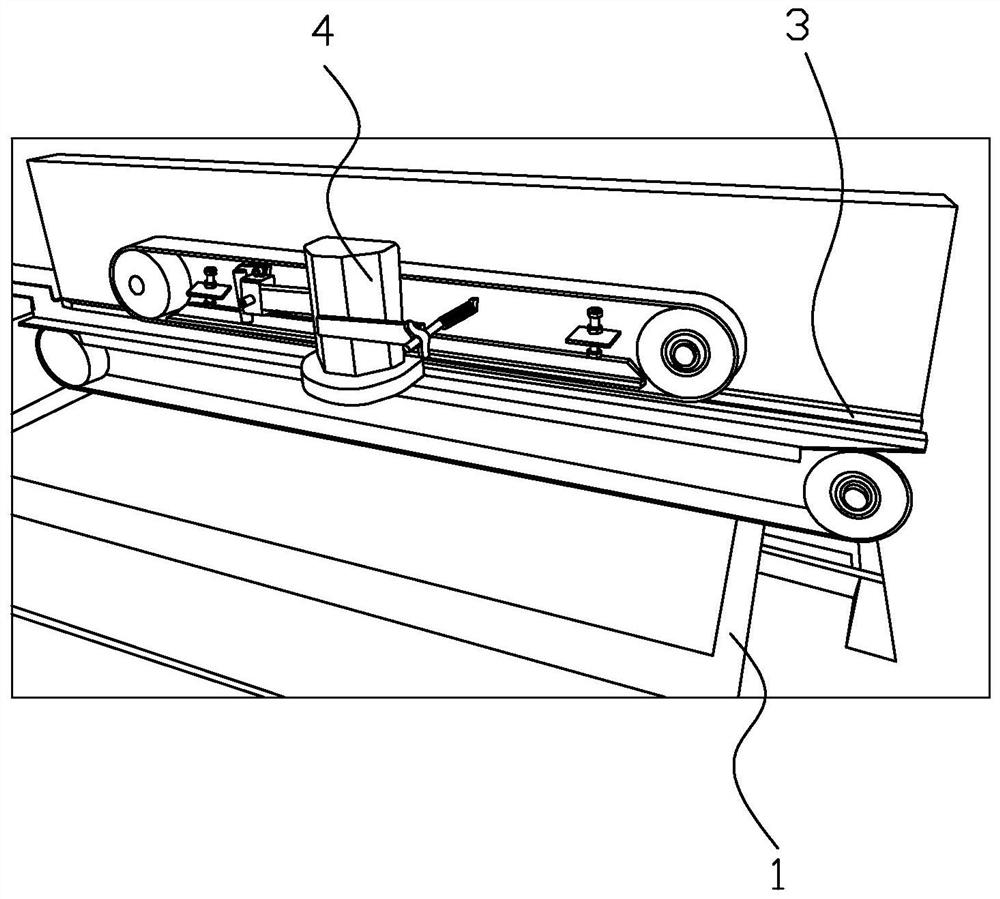

[0018] refer to Figure 1-Figure 3 , the preferred crab stick film peeling device of the present invention includes a PLC controller, a frame 1, a feeding mechanism 2 located on the frame 1, a crab stick delivery channel 3, a cutting mechanism 4, a second cutting mechanism, a second cutting mechanism, and a second cutting mechanism. A peeling mechanism 5, a film adsorption mechanism 6, a second conveyor belt 7, a second peeling mechanism 8, a second film adsorption mechanism 9 and a receiving box 10, the feeding mechanism 2 is a vibrating disc feeding mechanism, and the feeding mechanism 2 The crab sticks are transported through the crab stick delivery channel 3 and pushed to the feeding end of the first peeling mechanism 5, and the second cutting mechanism and the cutting mechanism 4 are symmetrically arranged on both sides of the crab stick deliver...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap