Continuous crystallization method of etimicin sulfate

A technology of etimicin and etimicin sulfate, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of cumbersome process and low yield, and achieve high-quality raw materials and products The effect of high yield and uniform distribution of crystal grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

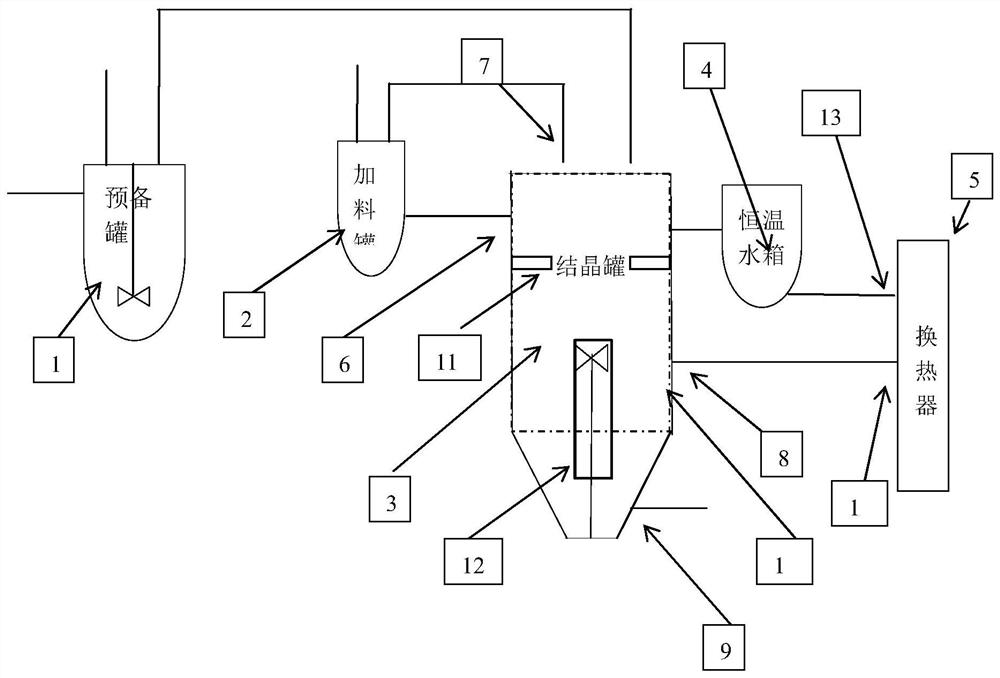

[0034] Such as figure 1 A continuous crystallizer shown, it includes a cooling crystallization system and a circulation constant temperature condensation system,

[0035] Wherein: the cooling crystallization system includes a feeding tank, a crystallization tank and a preparatory tank for ensuring that the feed is adjusted to pH, the crystallization stock solution is communicated with the liquid inlet of the preparatory tank through a pipeline, and the liquid outlet of the preparatory tank is connected with the crystallization tank 3 through a pipeline. The first liquid inlet provided on the top is connected, and the side wall of the crystallization tank is provided with an interlayer; the middle part of the crystallization tank is provided with a guide tube in the vertical direction, between the inner wall of the crystallization tank and the outer wall of the guide tube and is located in the crystallization tank. A baffle is set in the supernatant liquid area of the tank, t...

Embodiment 2

[0041] A process for continuous crystallization in a continuous crystallizer, comprising the following steps:

[0042] (1), the etimicin hydrolyzate enters the preparatory tank through the pipeline, and sulfuric acid is added dropwise under stirring, until the final pH of the mother liquor is 4.0, and the temperature is controlled at 20°C;

[0043] (2) Pass a constant temperature liquid into the interlayer of the side wall of the crystallizer to raise the temperature in the crystallizer until the temperature in the crystallizer is the same as that of the feed material, and the crystallization stock solution is pumped into the crystallizer from the first liquid inlet through the feed pump In the device; open the feeding tank, wherein the feeding tank contains methanol or ethanol with a concentration between 30% and 100%, the liquid in the clear liquid area of the crystallizer is passed into the feeding tank through the pipeline, and then passed into the crystallization through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com