Antistatic high-gloss polyketone material and preparation method thereof

An antistatic and polyketone technology, which is applied in the field of antistatic high-gloss polyketone materials and its preparation, can solve the problems of insufficient surface wear resistance and antistatic properties, easy to adhere to dust, easy to be scratched and bruised, and achieve excellent durability Cosmetic properties, excellent wear and scratch resistance properties, and the effect of excellent impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

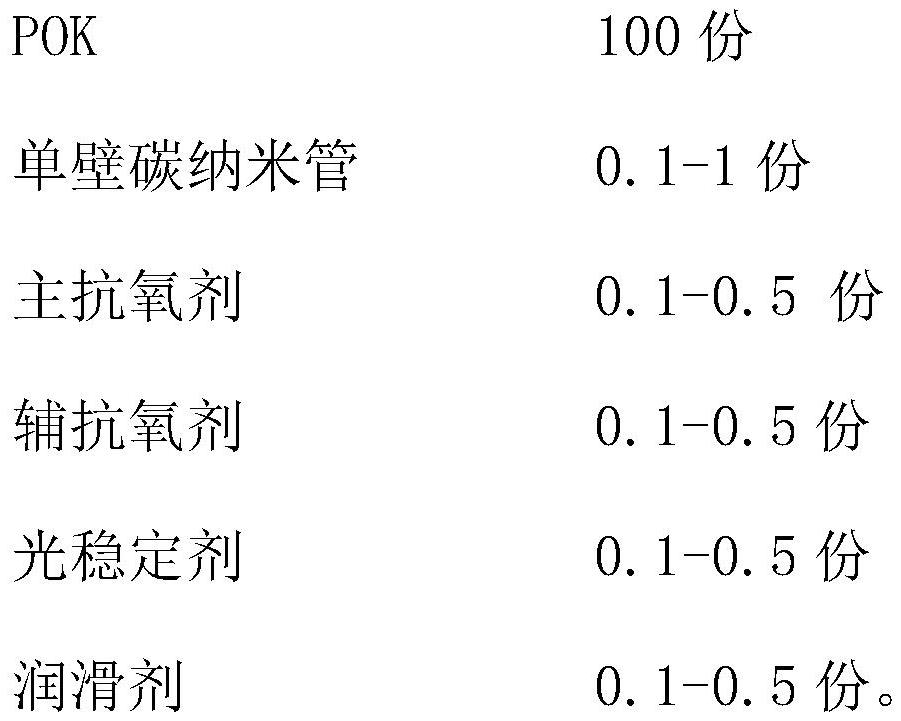

[0029] An antistatic high-gloss polyketone material comprises the following components by weight (unit: g):

[0030]

[0031] The preparation method is as follows: weigh the components of the above-mentioned materials according to the proportions in the examples, blend them at 100-250r / min for 5-10min, then melt and extrude them through a twin-screw extruder, pelletize and cool to obtain antistatic high-gloss polyketone Material,

[0032] The twin-screw extruder is divided into 9 sections, and the set temperatures are 180-200°C, 210-230°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C , 230-250°C, 230-250°C, 230-250°C, the screw speed is 300-600r / min.

Embodiment 2

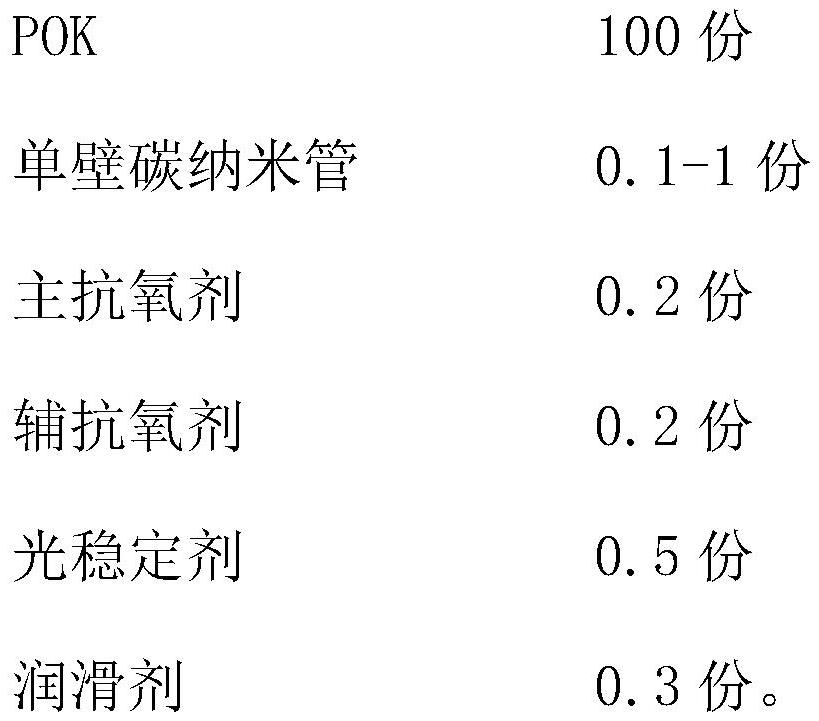

[0034] An antistatic high-gloss polyketone material comprises the following components by weight (unit: g):

[0035]

[0036] The preparation method is as follows: weigh the components of the above-mentioned materials according to the proportions in the examples, blend them at 100-250r / min for 5-10min, then melt and extrude them through a twin-screw extruder, pelletize and cool to obtain antistatic high-gloss polyketone Material,

[0037] The twin-screw extruder is divided into 9 sections, and the set temperatures are 180-200°C, 210-230°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C , 230-250°C, 230-250°C, 230-250°C, the screw speed is 300-600r / min.

Embodiment 3

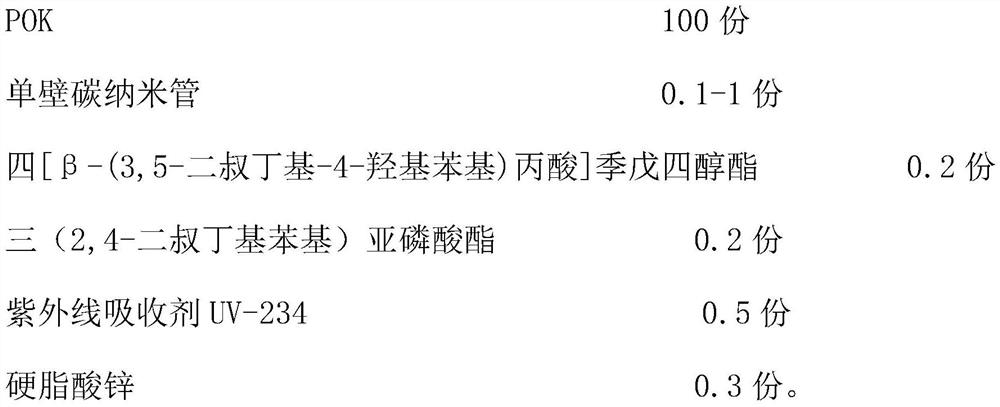

[0039] An antistatic high-gloss polyketone material comprises the following components by weight (unit: g):

[0040]

[0041] The preparation method is as follows: weigh the components of the above materials according to the proportions in the examples, blend them at 100-250r / min for 5-10min, then melt and extrude them through a twin-screw extruder, pelletize and cool to obtain antistatic high-gloss polyketone Material,

[0042] The twin-screw extruder is divided into 9 sections, and the set temperatures are 180-200°C, 210-230°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C, 230-250°C , 230-250°C, 230-250°C, 230-250°C, the screw speed is 300-600r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com