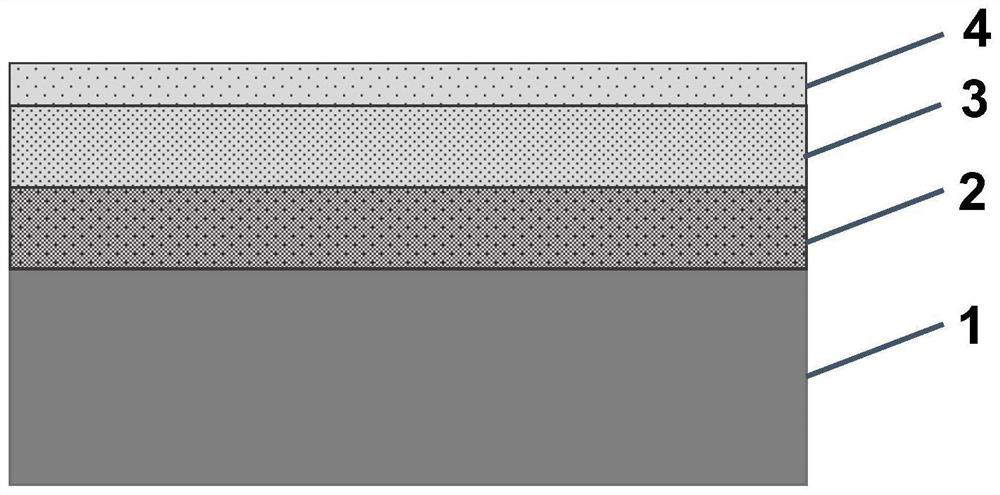

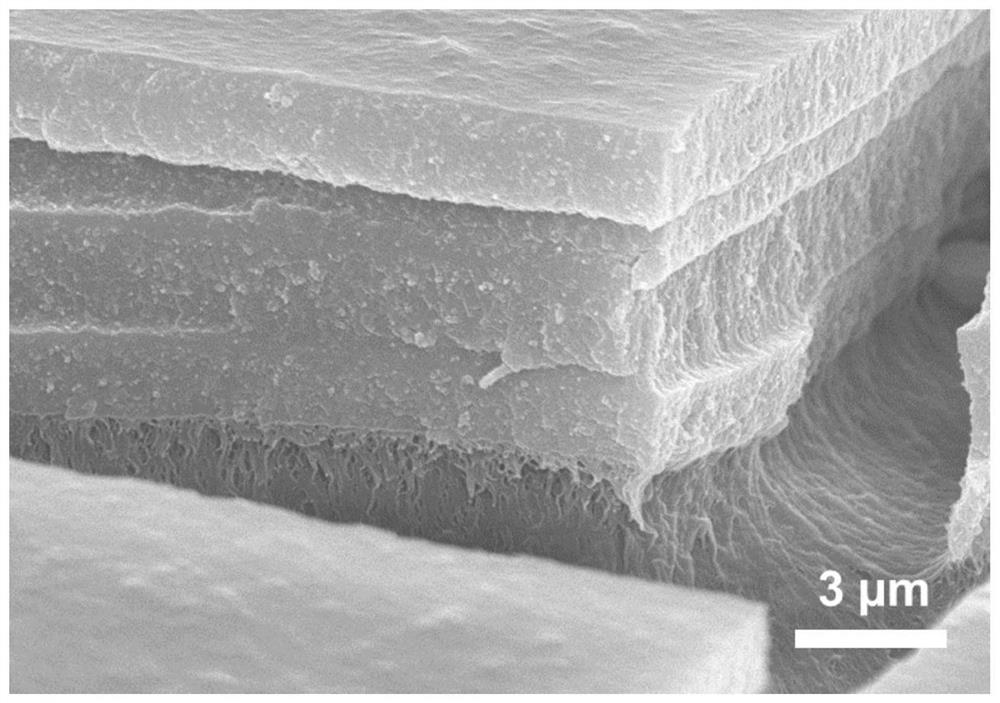

A kind of oxygen barrier coating and preparation method thereof

An oxygen barrier and coating technology, applied in the field of materials, can solve the problems of inorganic coating cracking and peeling, inorganic coating cracking, large roughness, etc., and achieve the effect of avoiding cracking and peeling, excellent adhesion, and blocking erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

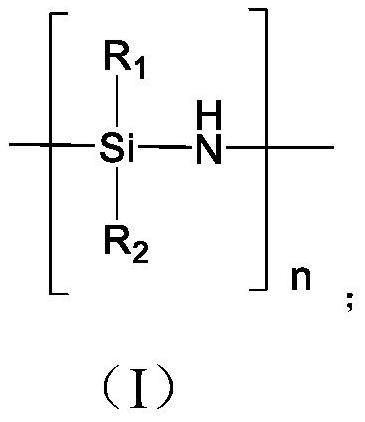

[0094] Preparation Example 1 Preparation of Polysilazane

[0095] Synthesis of polysilazane A: use a 1000mL three-necked glass flask as a reaction vessel, assemble mechanical stirring, rotate at 400 rpm, first replace the air in the reaction flask with nitrogen three times, make the reaction vessel a nitrogen atmosphere, add 500mL of solvent toluene , the temperature in the reaction flask was lowered to -10°C. join (CH 3 ) 2 SiCl 2 64.5g (0.5mol) and CH 3 (CH=CH 2 )SiCl 2 141g (1mol), after stirring for 20min, start to feed raw ammonia gas, the feed rate is 40mL / min, the ammonia gas is 0.77g / L under normal pressure, equivalent to a total of 84g (5mol), and the system is maintained during the process of passing ammonia. The temperature was -10°C. After the ammonia passing was completed, the stirring reaction was continued for 4 hours. After the reaction product was static for 6 hours, it was filtered with a 0.1 micron membrane filter, and the filtrate was further conc...

preparation example 2

[0097] Preparation Example 2 Preparation of Polysilazane

[0098] Synthesis of polysilazane B: using a 1000mL three-necked glass flask as a reaction vessel, equipped with mechanical stirring, rotating at 400 rev / min, first replacing the air in the reaction flask with nitrogen three times, making the reaction vessel a nitrogen atmosphere, adding the solvent xylene 500mL, and the temperature in the reaction flask was lowered to -10°C. join (CH 3 ) 2 SiCl 2 77.4g (0.6mol) and CH 3 SiHCl 2 115g (1mol), after stirring for 20min, start feeding raw ammonia gas, feeding rate is 40mL / min, ammonia gas is 0.77g / L under normal pressure state, equivalent to feeding 84g (5mol) in total, keep the system during the ammonia feeding process The temperature was -10°C. After the ammonia passing was completed, the stirring reaction was continued for 4 hours. After the reaction product was static for 6 hours, 0.1 micron membrane was used for filtration, and the filtrate was further concent...

preparation example 3

[0100] Preparation Example 3 Preparation of Polysilazane

[0101] Synthesis of polysilazane C: use a 1000mL three-necked glass flask as a reaction vessel, assemble mechanical stirring, rotate at 400 rpm, first replace the air in the reaction flask with nitrogen three times, make the reaction vessel a nitrogen atmosphere, add the solvent xylene 500mL, and the temperature in the reaction flask was lowered to -20°C. join H 2 SiCl 2 101g (1mol) and CH 3 SiHCl 2 115g (1mol), after stirring for 20min, start feeding raw ammonia gas, the feeding rate is 40mL / min, the ammonia gas is 0.77g / L under normal pressure, equivalent to 102g (6mol), and the system is maintained during the ammonia feeding process The temperature is -20°C. After the ammonia passing was completed, the stirring reaction was continued for 4 hours. After the reaction product was static for 6 hours, it was filtered with a 0.1 micron membrane filter, and the filtrate was further concentrated under vacuum heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com