Dry-mixed plastering mortar

A plastering mortar and dry mixing technology, which is applied in the field of building materials, can solve the problems of reducing the profit margin of mortar, reducing the thermal insulation performance of mortar, and dull color, etc., and achieve the effects of avoiding environmental pollution, reducing decoration costs, and enriching colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A dry-mixed plastering mortar, the formula includes: machine-made sand, cement, coal ash powder, iron and steel waste slag powder, cellulose ether, pigment and thermal insulation dry powder; the parts by weight of each component are: 750 parts of machine-made sand, 110 parts by weight 30 parts of cement, 30 parts of coal ash powder, 20 parts of steel waste slag powder, 0.08 parts of cellulose ether, 3 parts of pigment and 4 parts of thermal insulation dry powder, wherein the cement is 425 cement, and the machine-made sand is graded. The diameter is 0.35-0.5mm, the pigment is one or more mixtures of azurite, stone green, cinnabar, realgar and graphite, and the heat preservation dry powder is expanded perlite powder, expanded vitrified microspheres and EPS particles according to the ratio of 1:1: A mass ratio of 1 is mixed.

Embodiment 2

[0019] A kind of dry mix plastering mortar, formula comprises: machine-made sand, cement, coal ash powder, iron and steel waste slag powder, cellulose ether, pigment and thermal insulation dry powder; The parts by weight of each component are: 800 parts of machine-made sand, 120 parts 40 parts of cement, 40 parts of coal ash powder, 30 parts of steel waste slag powder, 0.15 parts of cellulose ether, 5 parts of pigment and 6 parts of thermal insulation dry powder, wherein the cement is 425 cement, the machine-made sand has been graded, and the sand particles The diameter is 0.35-0.5mm, the pigment is one or more mixtures of azurite, stone green, cinnabar, realgar and graphite, and the heat preservation dry powder is expanded perlite powder, expanded vitrified microspheres and EPS particles according to the ratio of 1:1: A mass ratio of 1 is mixed.

Embodiment 3

[0021] A dry-mixed plastering mortar, the formula includes: machine-made sand, cement, coal ash powder, iron and steel waste slag powder, cellulose ether, pigment and thermal insulation dry powder; the parts by weight of each component are: 760 parts of machine-made sand, 115 parts 35 parts of cement, 35 parts of coal ash powder, 25 parts of steel waste slag powder, 0.1 part of cellulose ether, 4 parts of pigment and 5 parts of thermal insulation dry powder, wherein the cement is 425 cement, the machine-made sand has been graded, and the sand particles The diameter is 0.35-0.5mm, the pigment is one or more mixtures of azurite, stone green, cinnabar, realgar and graphite, and the heat preservation dry powder is expanded perlite powder, expanded vitrified microspheres and EPS particles according to the ratio of 1:1: A mass ratio of 1 is mixed.

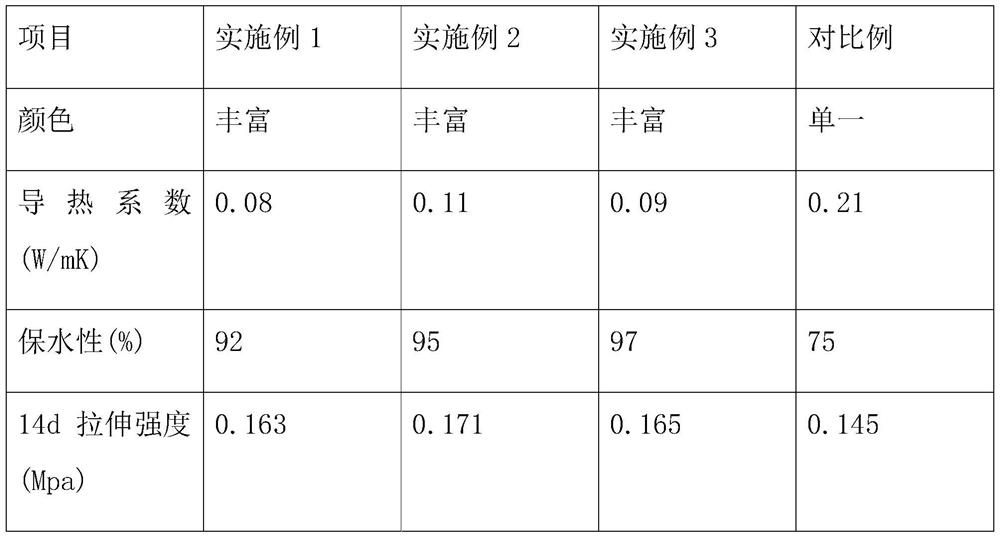

[0022] The dry-mixed plastering mortar obtained in the above-mentioned embodiments is observed and tested respectively, and the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com