Additive for two-acid chemical polishing of sandblasted surface aluminum alloy, chemical polishing solution and preparation method of additive for two-acid chemical polishing of sandblasted surface aluminum alloy

A technology of chemical polishing and aluminum alloy, applied in the field of metal surface treatment, to achieve the effects of improving product yield, simple preparation method and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

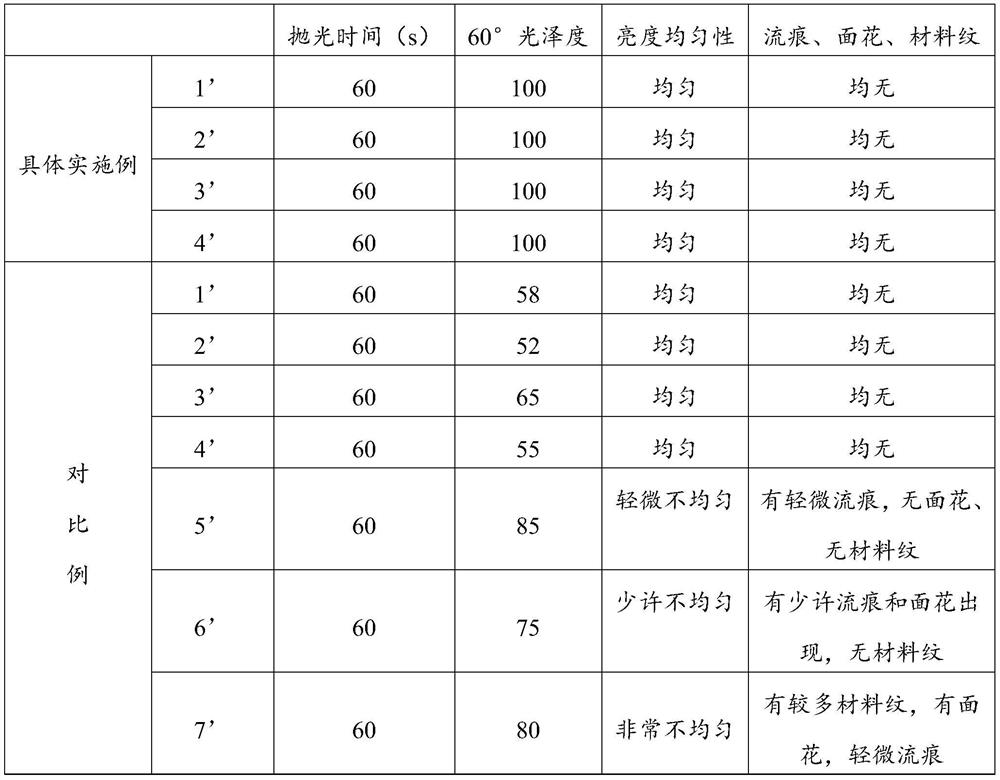

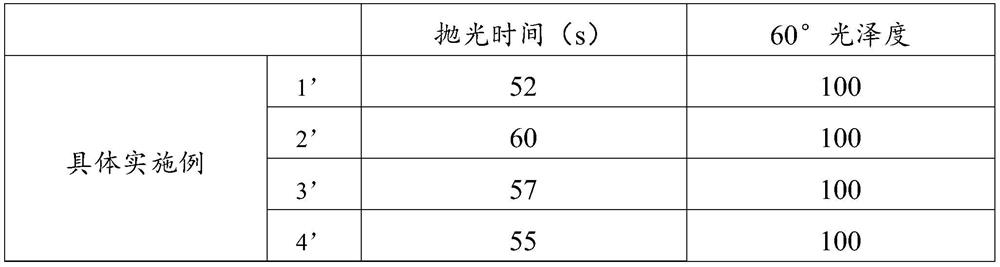

Examples

Embodiment Construction

[0030] In order to be able to understand the technical means of the present invention more clearly and implement it according to the contents of the description, the specific embodiments of the present invention will be further described in detail below in conjunction with specific examples. The following examples are used to illustrate the present invention, but not to limit it scope of the invention.

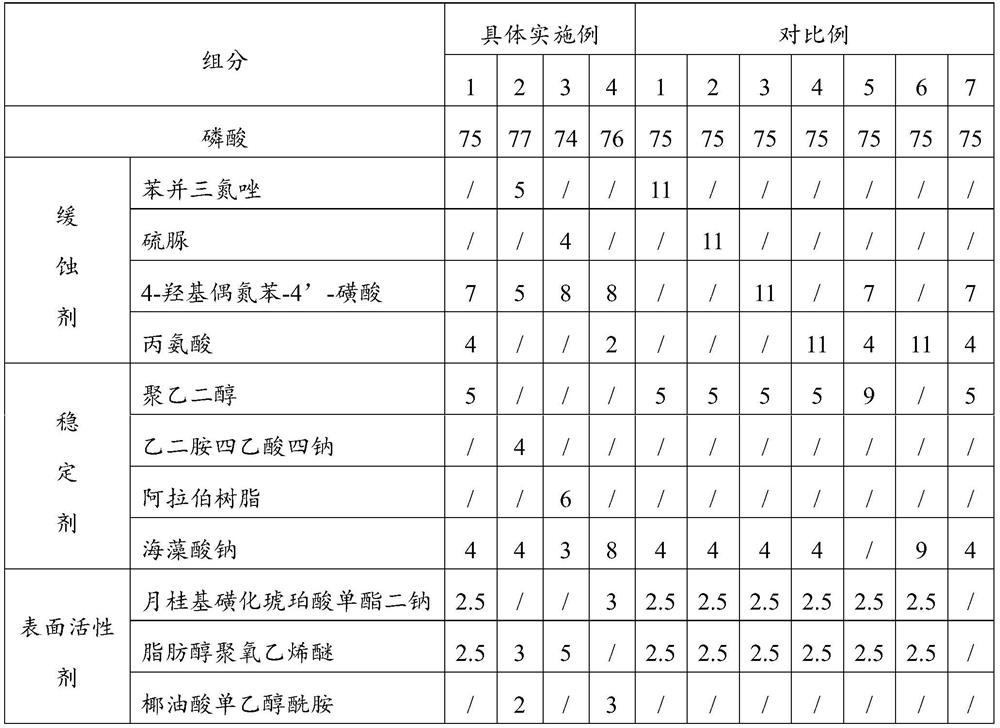

[0031] Carry out the preparation of additives for chemical polishing according to the following preparation method: After weighing each raw material according to the mass percentage in Table 1, first add the weighed surfactant and stabilizer to 1 / 2 to 3 / 4 of the total amount of phosphoric acid and stir until it is completely dissolved to obtain the first primary mixture, then add the weighed corrosion inhibitor into the remaining phosphoric acid and stir until it is completely dissolved to obtain the second primary mixture, and finally mix the first and second primary mixtures ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap