Vacuum plated copper jewelry

A technology of vacuum plating and copper decoration, applied in decorations, other household appliances, household appliances, etc., can solve the problems of easy peeling off of the coating and anti-oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Below in conjunction with accompanying drawing, the present invention is described in further detail:

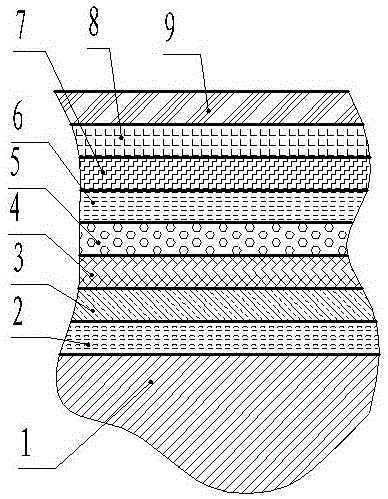

[0007] Such as figure 1 The hand vacuum copper-plating ornament shown includes a copper substrate 1, and the surface of the copper substrate 1 is sequentially coated with a first brass tin layer 2, an alkali copper layer 3, a copper sulfate layer 4, a cupronickel tin layer 5, and a second Brass tin layer 6, palladium cobalt layer 7, titanium nitride layer 8 and gold layer 9, gold layer 9 is the surface layer of copper decoration. The coating sequence of the present invention is especially suitable for the electroplating of copper ornaments with complex workmanship without artificial gemstone inlays. The resulting fashion jewelry coating has strong bonding force and oxidation resistance to the substrate, and the plating layer will not fall off or fade when worn 3 to 4 times. The phenomenon.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap