A kind of preparation technology of tensile type polyester fiber industrial yarn

A polyester fiber and preparation process technology, applied in the field of polyester fiber, can solve the problems of easy softening of polyester fiber, influence of tensile strength, secondary damage, etc., and achieve the effects of reducing fluidity, reducing safety hazards, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

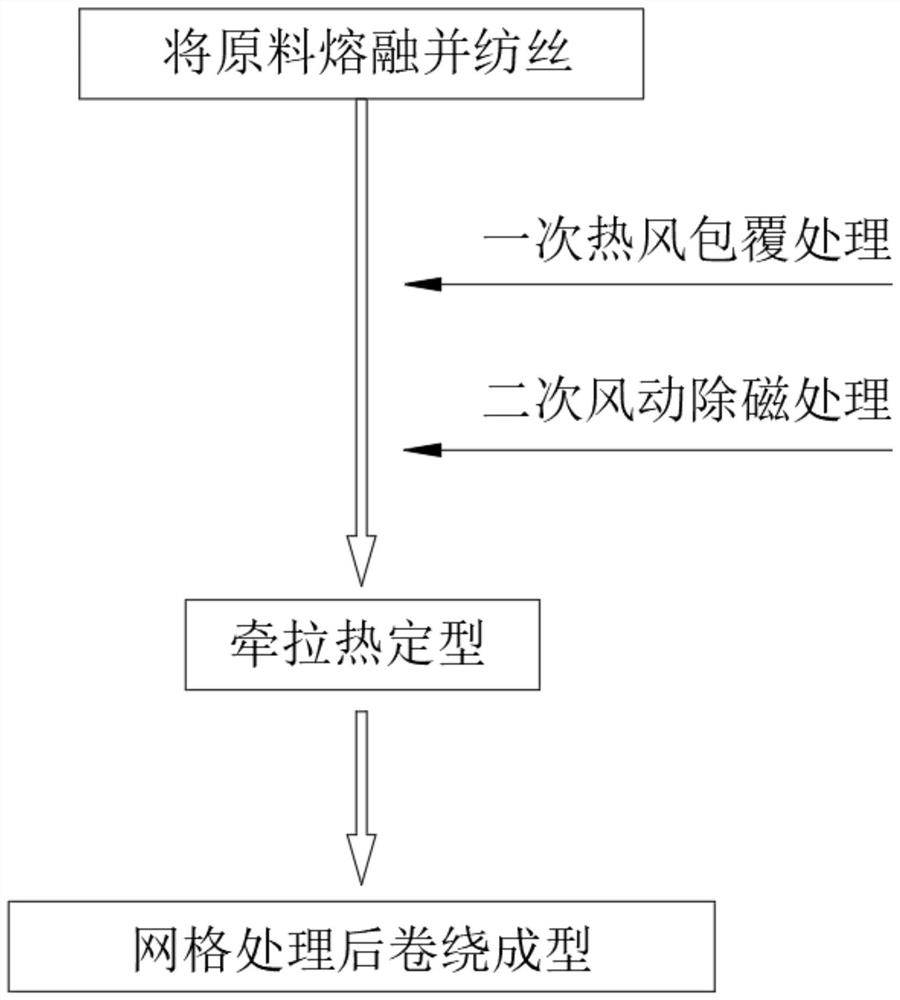

[0047] see figure 1 , a preparation process of tensile-resistant polyester fiber industrial yarn, comprising the following steps:

[0048] S1, crush the polyester material to form a master batch, and heat it at a high temperature to obtain a molten master batch for use;

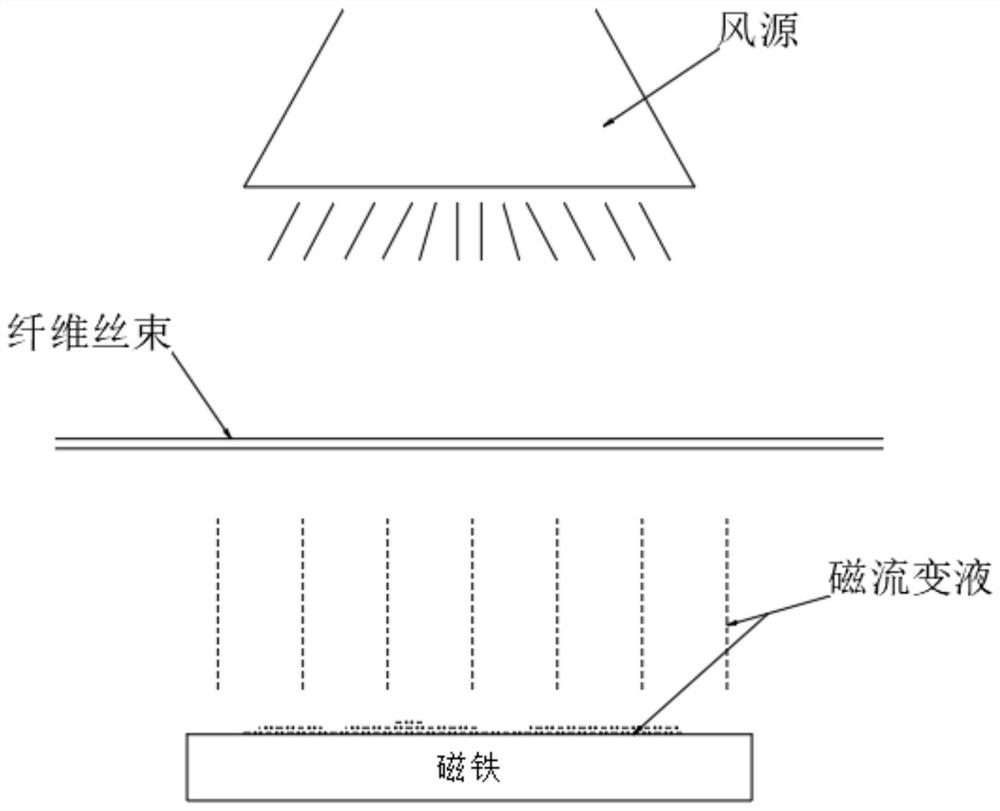

[0049] S2. Spin the molten masterbatch through the spinning assembly to obtain fiber filaments. First, the fiber filaments are pretreated. The pretreatment of the fiber filaments is as follows: uniformly pass the fiber filaments through the magnetorheological fluid, so that part of the magnetorheological fluid is in the The liquid is hung on the fiber to make the fiber magnetic;

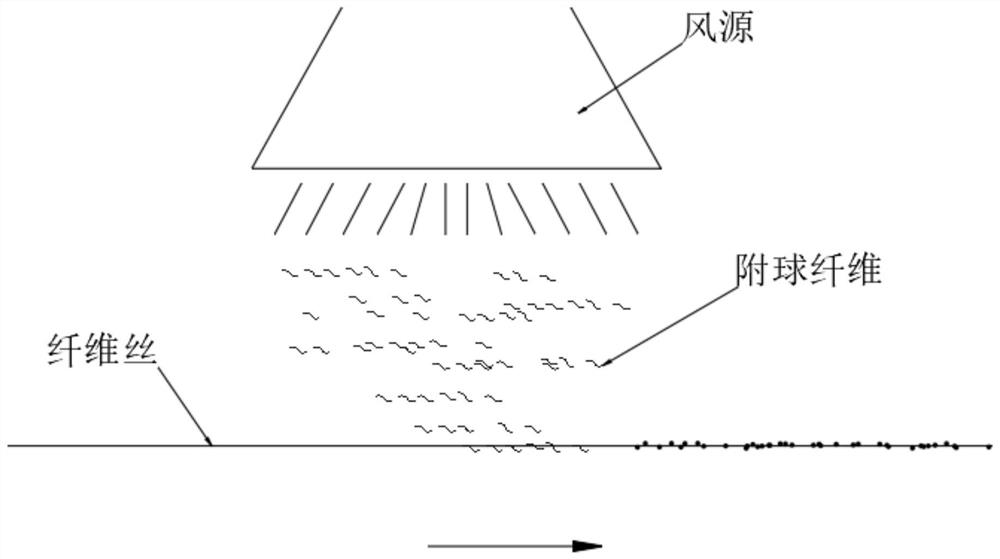

[0050] S3, see figure 2 , the arrow in the figure indicates the moving direction of the fiber, and then the pretreated fiber is evenly moved to the right, and a hot air coating treatment is performed at the same time. Move, and make the attached ball fiber attach to the fiber filament, so as to form a layer of droplet wrapping l...

Embodiment 2

[0057] The coated magnetic ball 2 is wrapped with magnetized water, and the coated magnetic ball 2 is made of a hot-melt material. In the subsequent heat setting operation, the coated magnetic ball 2 is heated and melted and dripped to make its inner magnetization. Water is lost, thereby realizing demagnetization. The end of the anti-droplet staple fiber 1 extends into the coated magnetic ball 2 and contacts with the magnetized water. Due to the water absorption of natural fibers, the anti-droplet short fiber 1 gradually absorbs the coated magnetic ball 2. The inner magnetized water makes the anti-droplet staple fibers 1 gradually have magnetic properties, so that there is a certain adsorption force between multiple anti-droplet short fibers 1, and at the same time, the entire anti-droplet short fibers 1 can be adsorbed with the surface of the fiber filaments, and then A plurality of anti-droplet staple fibers 1 are brought close to each other to change their loose state, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com