Air jet loom tension adjusting equipment prepared from new semiconductor materials

An air-jet loom and tension adjustment technology, which is applied in looms, textiles, textiles and paper making, etc., can solve the problems of uneven winding, affecting processing quality, stress deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

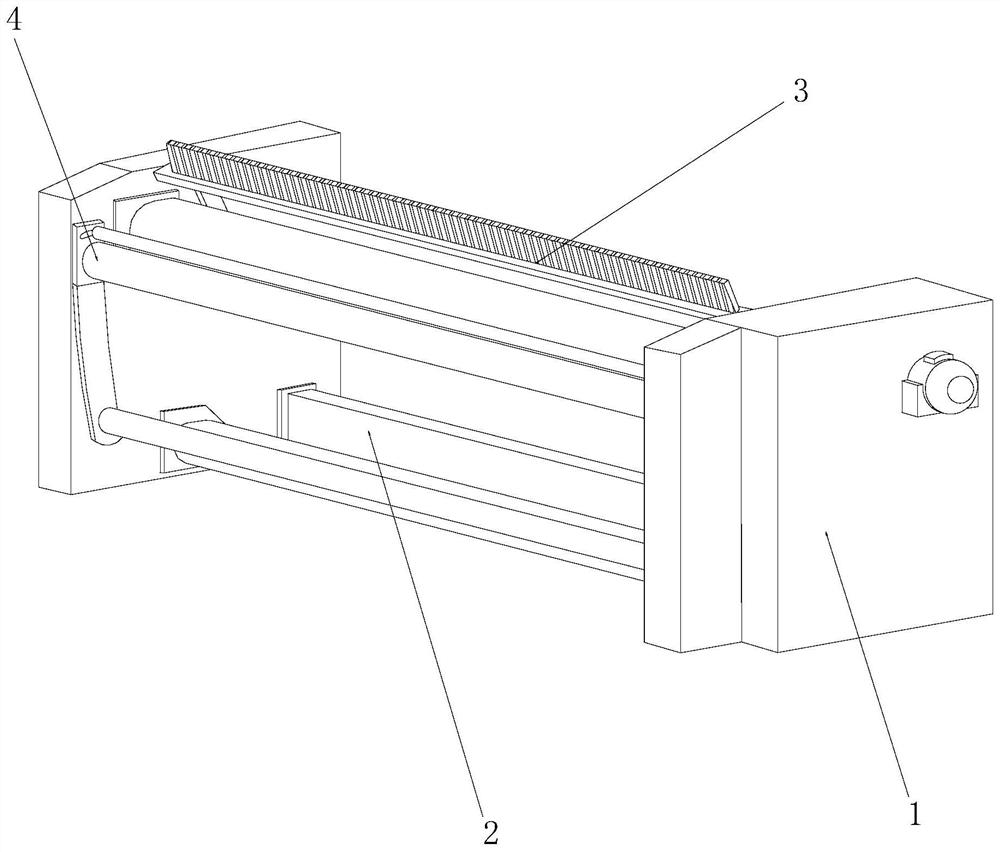

[0027] Example 1: Please refer to Figure 1-Figure 4 , the specific embodiments of the present invention are as follows:

[0028] The invention provides an air-jet loom tension adjustment device made of new semiconductor materials, the structure of which includes a motor box 1, a support 2, a beating device 3, and a coiling device 4, and the motor box 1 is welded and connected to the right side of the support 2. On the side, the beater 3 is installed on the upper end of the middle part of the support 2, and the crimping device 4 is movably engaged in front of the support 2.

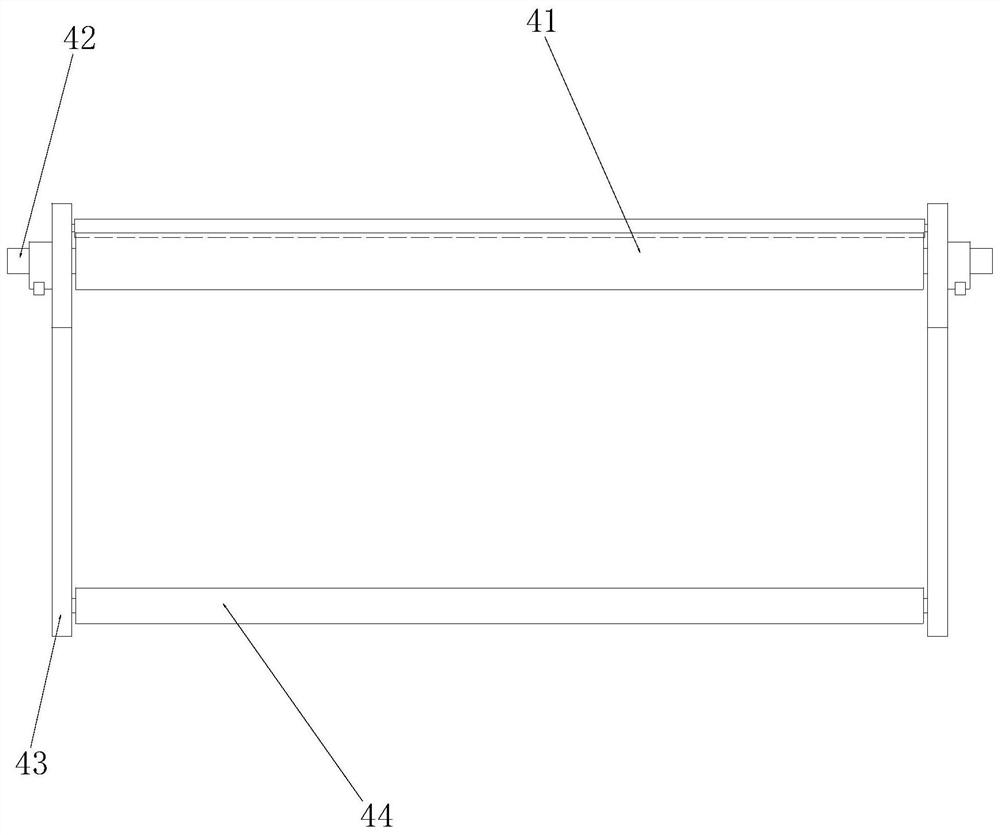

[0029] The rolling device 4 is composed of a regulator 41, a connecting block 42, a rocker arm 43, and a rolling roller 44. There are two connecting blocks 42, and the two connecting blocks 42 are installed on the left and right sides of the regulator 41. On the side, there are two rocker arms 43 in total, and the two rocker arms 43 are respectively embedded and connected under the left and right ends of...

Embodiment 2

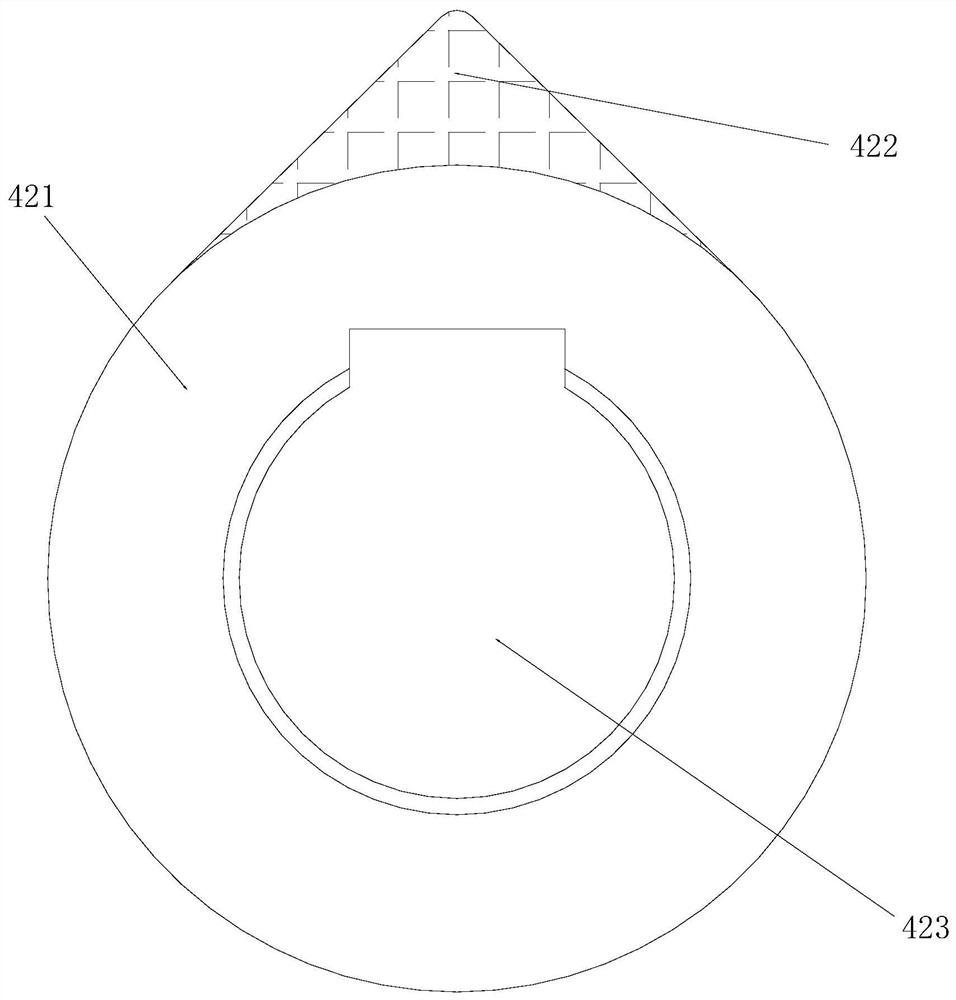

[0034] Example 2: Please refer to Figure 5-Figure 9 , the specific embodiments of the present invention are as follows:

[0035] The present invention provides an air-jet loom tension adjustment device made of new semiconductor materials. The adjustment roller 414 is composed of an outer casing 141, a support shaft 142, an adjustment mechanism 143, a magnetic block 144, and a brake ring 145. The outer casing 141 is movable. Closed on the surface of the support shaft 142, the middle part of the adjustment mechanism 143 is welded and connected to the inner bottom of the jacket 141, the magnetic block 144 is made of a magnet material, and the magnetic block 144 is embedded and connected below the left end of the adjustment mechanism 143. The brake ring 145 is provided with a drop-shaped structure on the surface, and the brake ring 145 is riveted on the surface of the support shaft 142. The brake ring 145 with a water-drop-shaped structure on the surface will move The drop-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com