Novel casing tong jaw plate device

A technology of casing tongs and jaw plates, which is applied in the direction of casing, drill pipe, drilling equipment, etc., can solve problems such as increasing labor intensity of workers, damage to pipe strings and casing tongs, and affecting make-up and breakout operations, etc., to achieve weakening The effect of labor intensity, easy replacement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

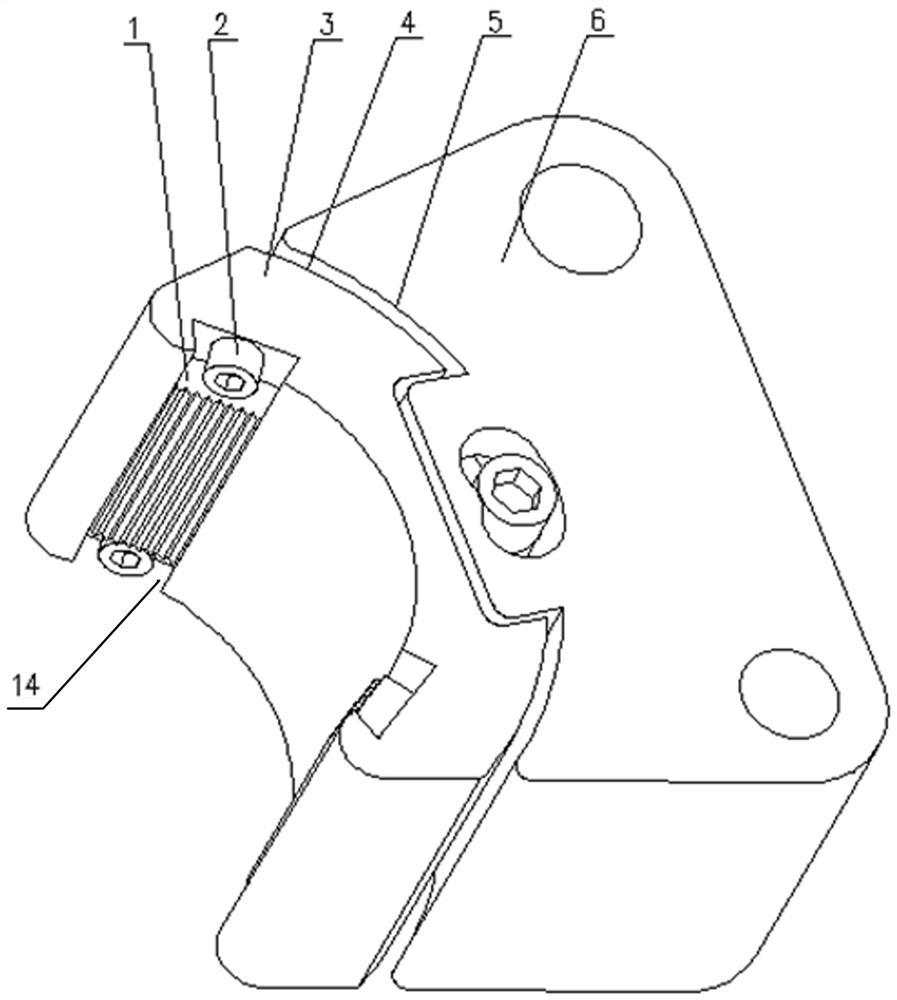

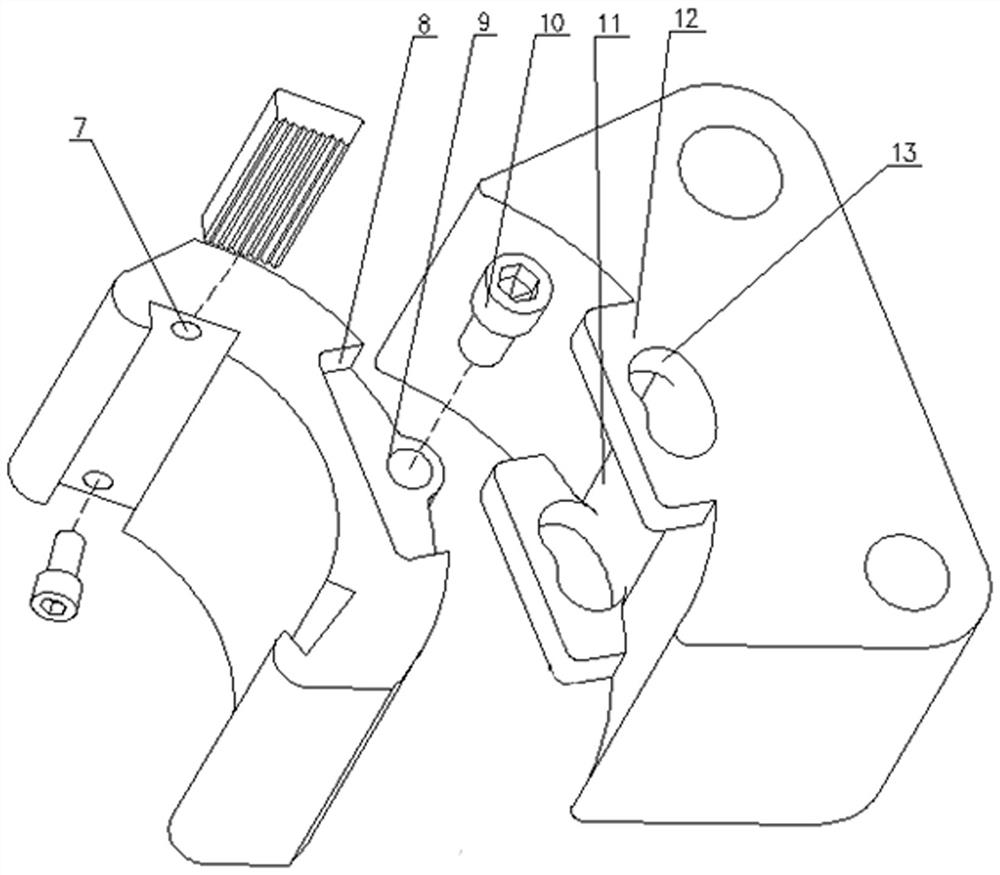

[0017] Please refer to figure 1 and figure 2 , which shows a new casing jaw jaw device, including a tooth plate 1, a tooth seat 3, and a jaw plate 5. The front surface of the tooth base 3 is symmetrically provided with a tooth plate groove 14, and the top and bottom of the tooth plate groove 14 are symmetrically provided with threaded holes Ⅱ7, and the threaded holes Ⅱ7 are fixed with limit screws 2, and the tooth plate 3 passes through the limit at the upper and lower ends. The screw 2 is clamped and fixed in the tooth plate groove 14; in contrast, the back of the tooth base 3 forms an outwardly convex arc surface I4, and the side of the jaw plate 6 close to the tooth base 3 forms a concave arc surface Ⅱ5, there is a gap between the arc surface Ⅰ4 and the arc surface Ⅱ5, the upper and lower ends of the middle of the arc sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com