Evaporation kettle with injection regulation and control function

An evaporating kettle and functional technology, which is applied to the field of evaporating kettles with the function of regulating and injecting, can solve the problems of inconvenient use, too much liquid in the evaporating kettle, and inability to process normally, and achieve the effects of facilitating observation, speeding up the evaporation speed, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

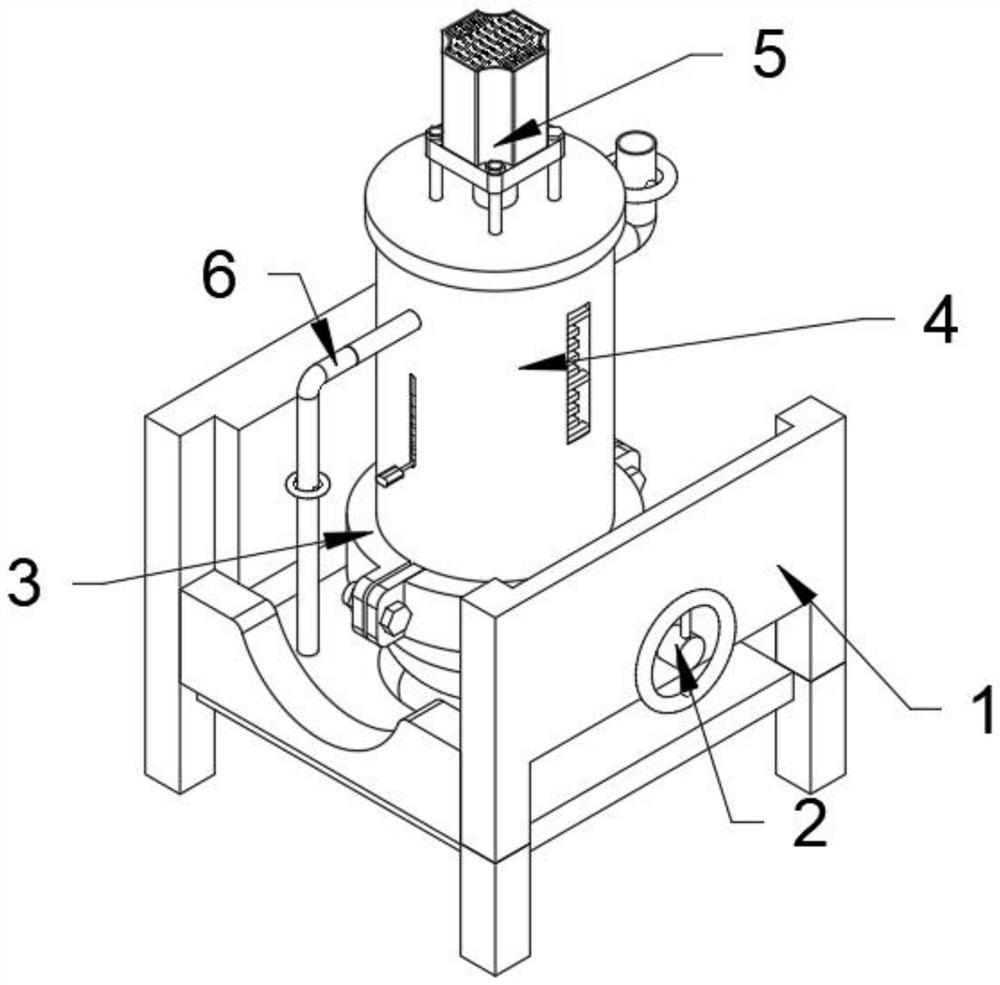

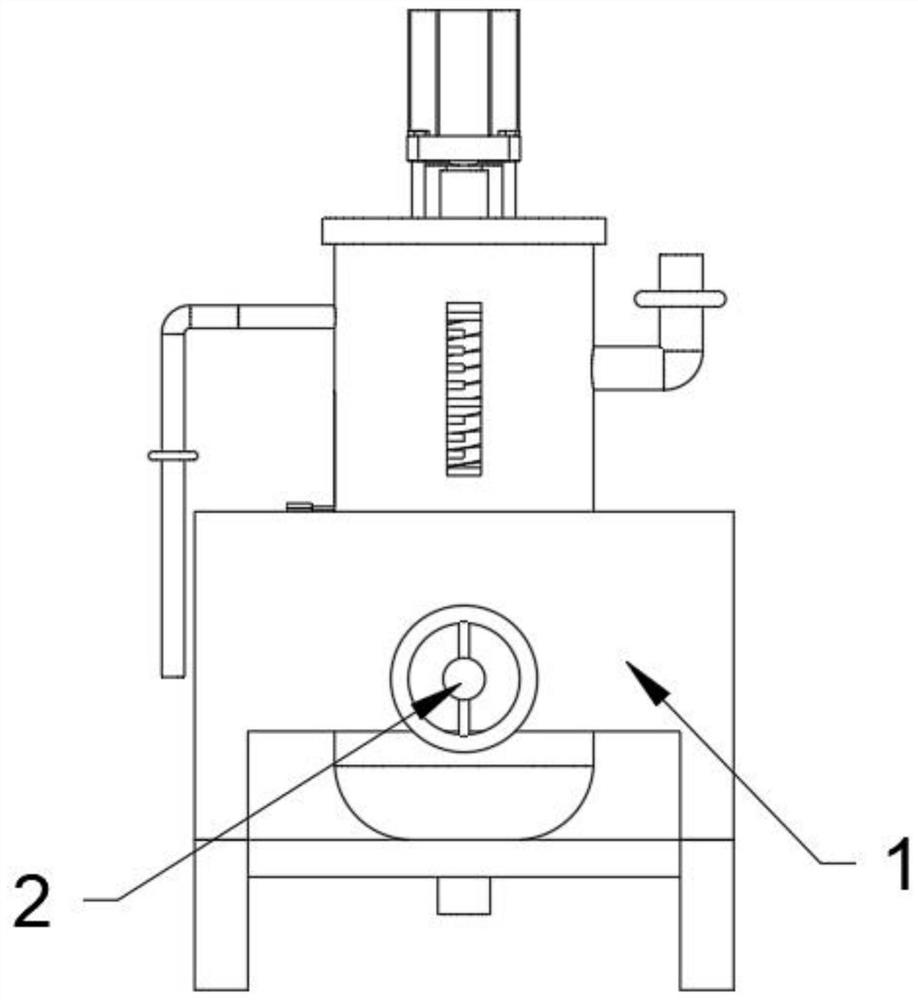

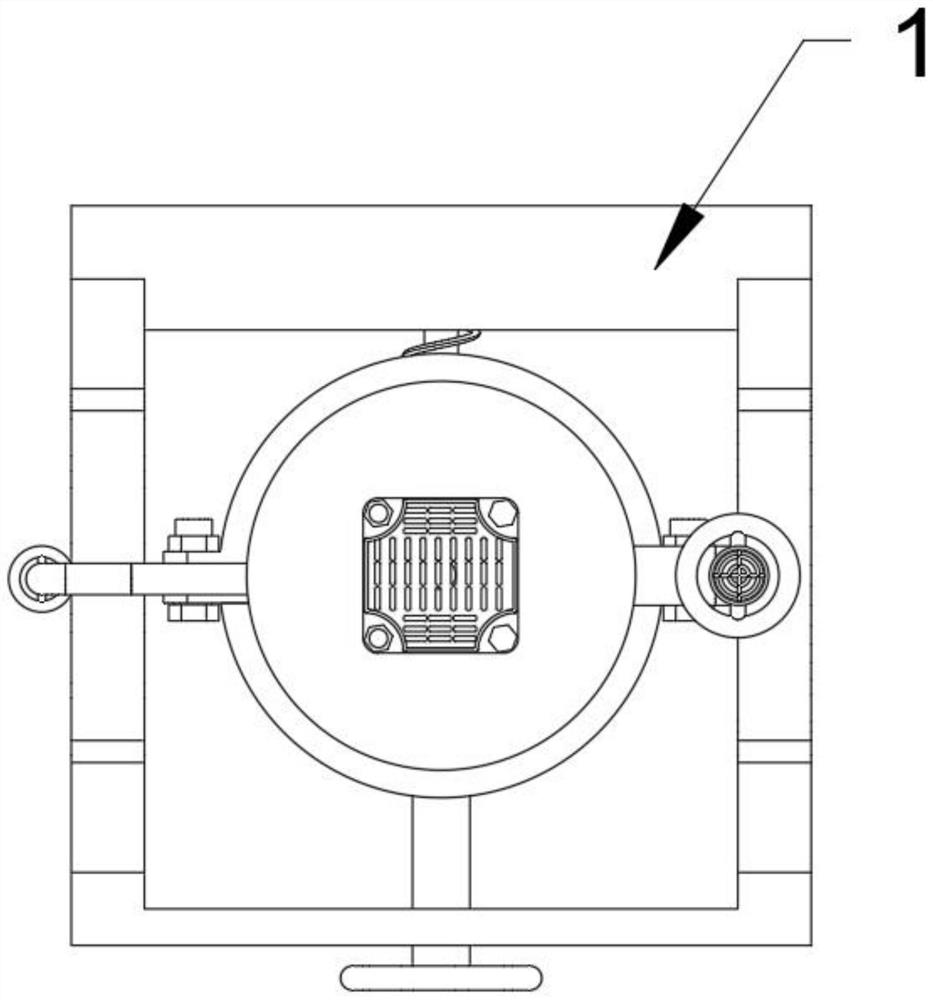

[0033] as attached figure 1 to attach Figure 9 Shown:

[0034]The present invention provides an evaporating kettle with the function of regulating and injecting, which includes: an adjusting mechanism 2, an auxiliary clamping mechanism 3, an evaporating kettle 4, and a driving stirring mechanism 5, and the adjusting mechanism 2 is screwed to the front end of the bracket 1; the auxiliary clamping mechanism The mechanism 3 is elastically connected to the inner front end of the bracket 1; the evaporator 4 is plugged into the inner position of the adjustment mechanism 2 and the auxiliary clamping mechanism 3; the driving stirring mechanism 5 is screwed to the top position of the evaporator 4, and the evaporator 4 A liquid level maintaining mechanism 6 is plugged into the left end of the liquid level maintaining mechanism 6; the liquid level maintaining mechanism 6 includes an overflow pipe 601, an overflow valve 602, a length adjustment pipe 603 and an adjustment block 604, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap