Flue gas filtering device

A filter device and flue gas technology, applied in the directions of dispersed particle filtration, separation method, dispersed particle separation, etc., can solve the problems of falling on the filter bag, inconvenient use, clogging of the filter bag, etc., to prevent agglomeration, improve the use of Longevity, the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

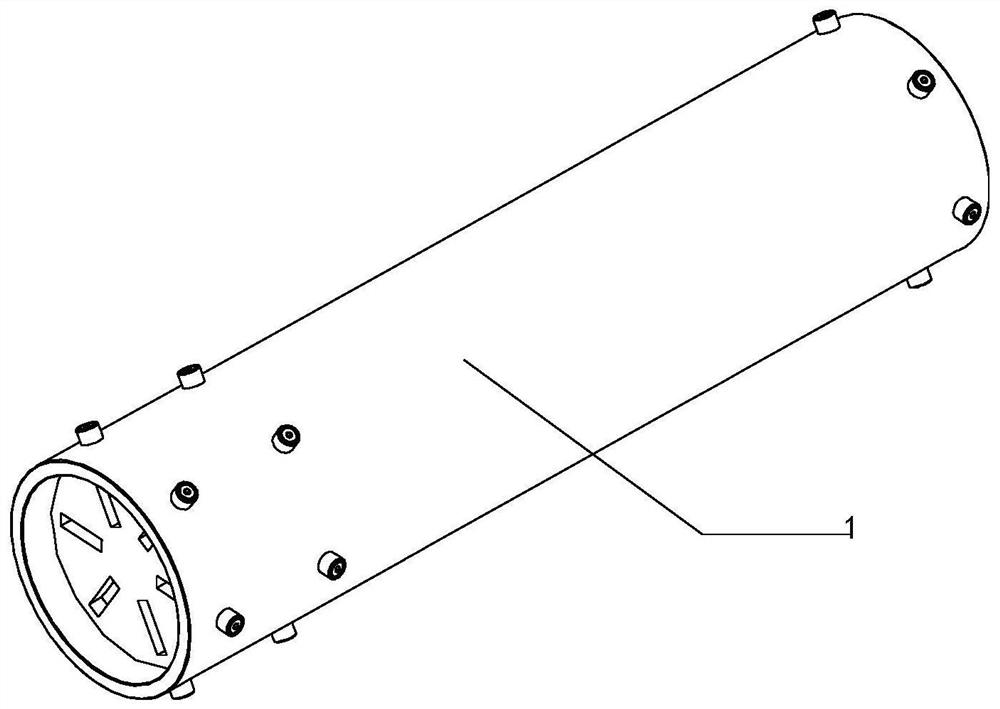

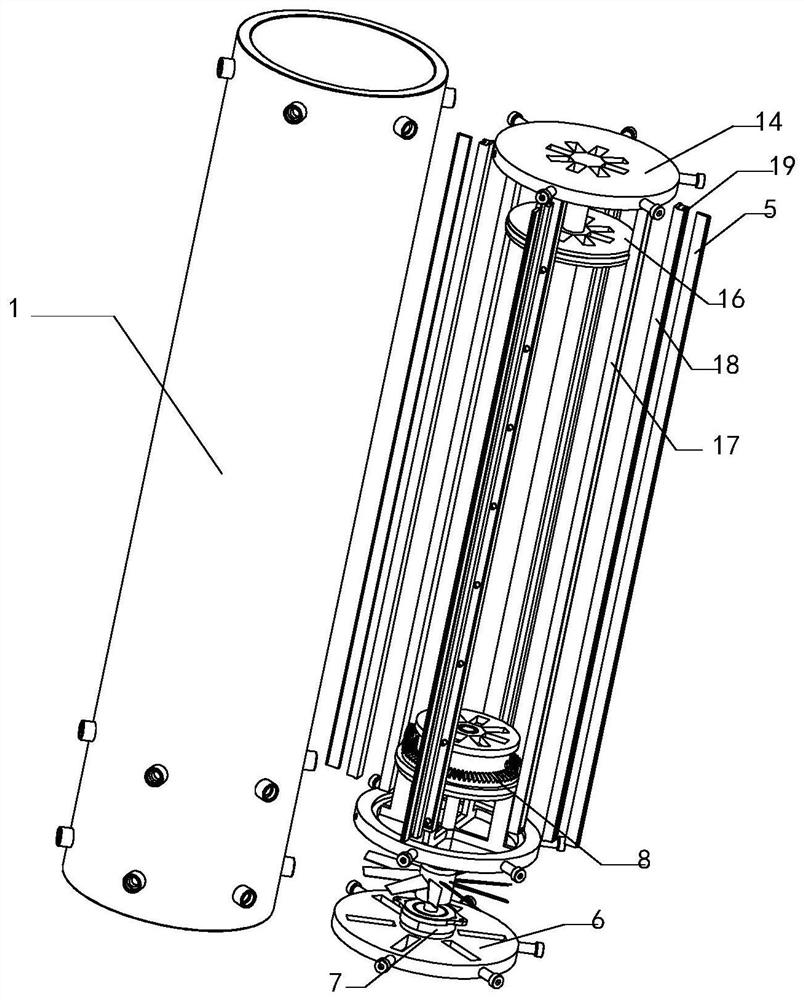

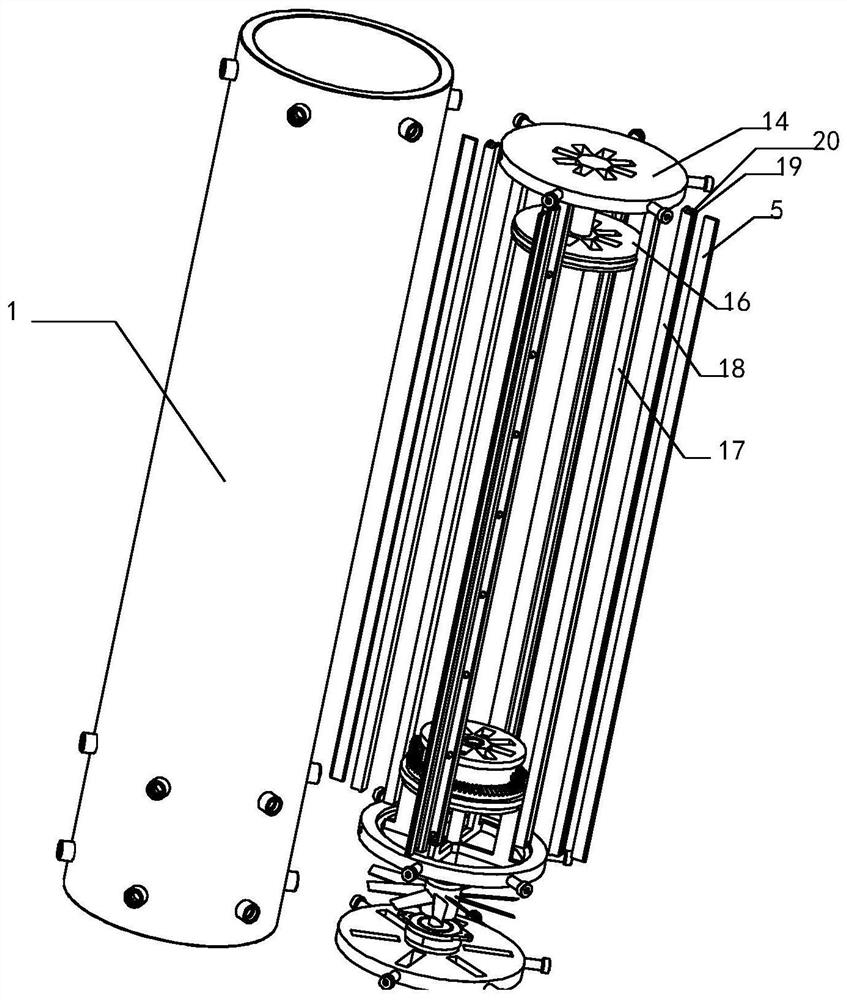

[0034] Such as figure 1 , figure 2 , Figure 4 with Figure 9 As shown, a flue gas filtering device proposed in this embodiment is suitable for use in thermal power plants, including: a flue gas pipe 1, a mounting frame 2, a mounting plate 6, and a linkage assembly 8, and the mounting frame 2 is installed on the flue gas pipe 1 On the inner wall, a rotating disk 3 coaxial with the flue gas pipe 1 is rotated above the mounting bracket 2, and a mounting block 4 is installed on the circumferential side of the rotating disk 3, and a scraper for cleaning the inner wall of the flue gas pipe 1 is installed on the mounting block 4 5. The mounting plate 6 is installed on the inner wall of the flue gas pipe 1 and is located in the direction of the mounting frame 2 away from the scraper 5. The motor 7 is installed on the mounting plate 6, and the linkage assembly 8 is mounted on the mounting frame 2 and acts on the rotating disk 3. , the output shaft of the motor 7 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com