Online cutting-off device and online automatic tube cutting method

A technology of cutting device and clamping device, which is applied in metal processing and other directions, can solve the problems of difficult to obtain high-precision pipe length, etc., and achieve the effect of stable clamping, not easy to shake, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the objects, technical solutions, and advantages of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings. Only in this declaration, the present invention appears or is about to appear on, lower, left, right, before, after, within, and other orientation, only in the present invention, is not specifically for the present invention. limited.

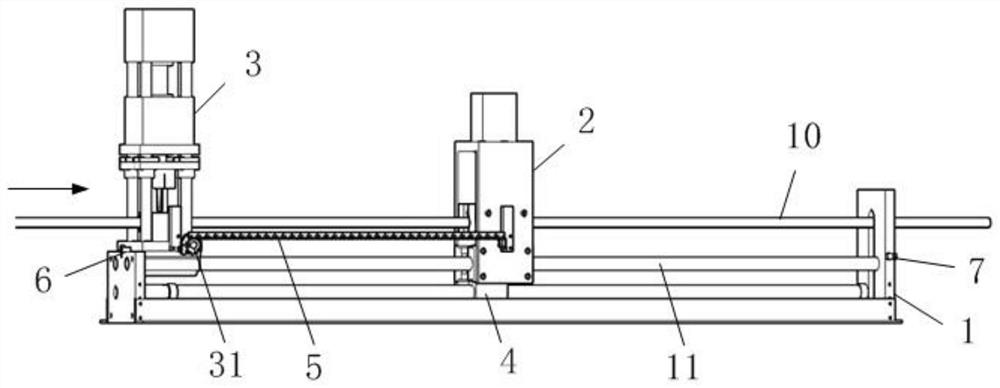

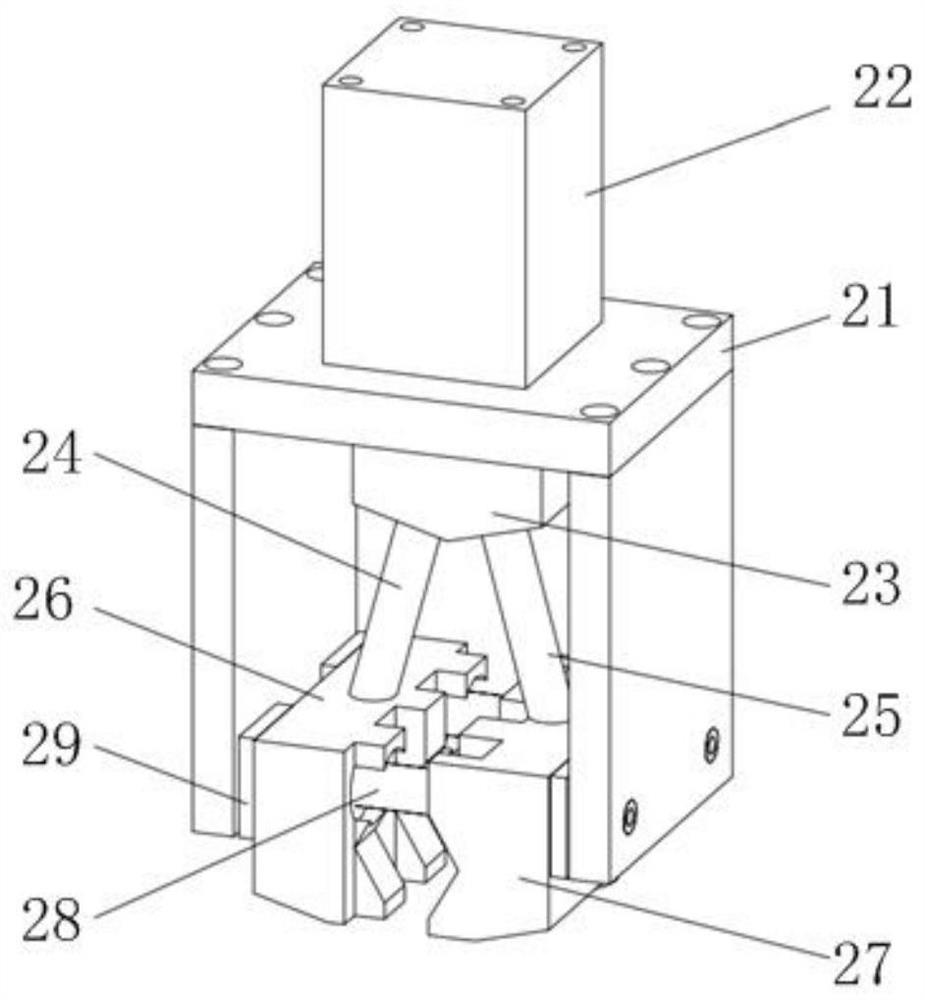

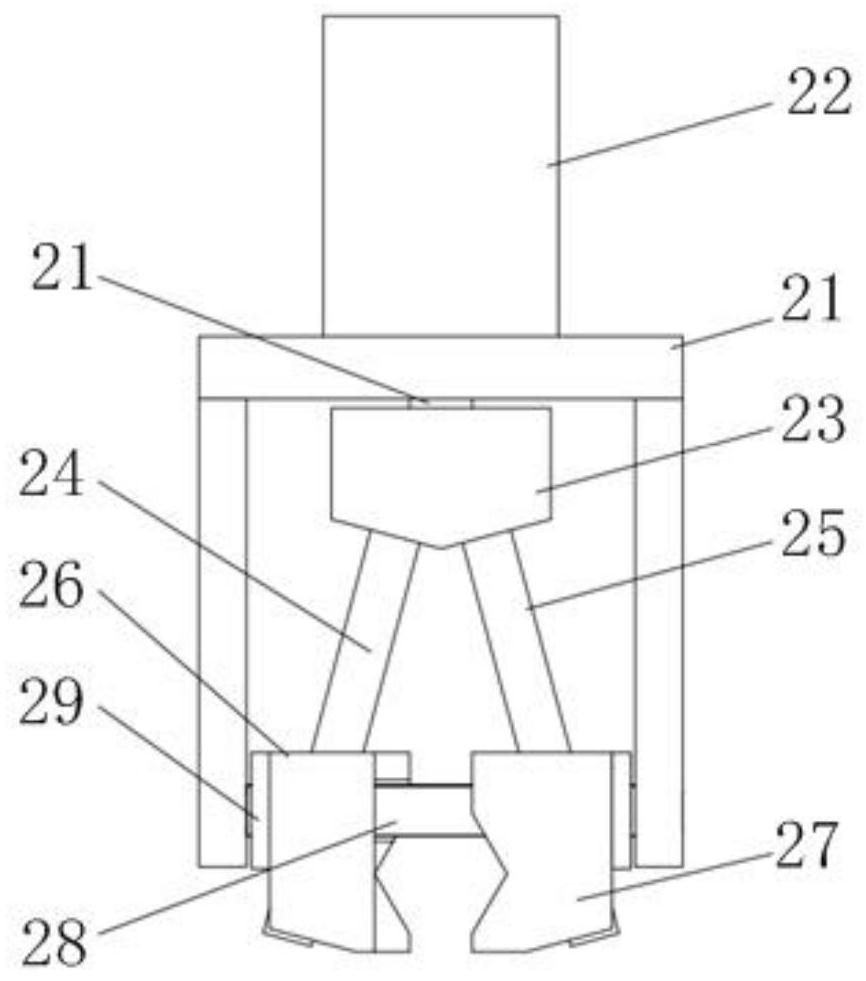

[0043] See figure 1 with Figure 10 A line cutting device according to the present invention provides, comprises a frame 1, the clamping device 10 for clamping the pipe 2, the pipe cutting apparatus 10 for cutting 3, driving means for moving the clamping device 4 of the second drive, and 3 is connected between the cutting means and clamping means 2 of the chain 5, the gripping means 2 and 3 against the cutting means in an initial position; pipe 10 passes through the cutting device 3 from the inlet end of the pipe rack 1, and kept to the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com