Reel speed regulating device of high-speed winding machine

A technology of speed regulating device and winding machine, which is applied in the directions of coiling strips, transportation and packaging, thin material processing, etc. It can solve the problems that the tension cannot be eliminated in time and the method of measuring the coil diameter is inaccurate, and achieve low vibration and accuracy. The effect of detecting the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

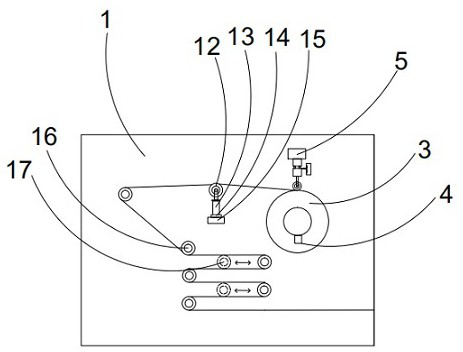

[0026] Such as Figure 1-3 As shown, a high-speed winding machine reel speed regulating device includes a frame 1 and a motor 2, a winding roller 3 is rotated on the frame 1, and the central axis of the winding roller 3 is connected to the output end of the motor 2, It is characterized in that: a rotational speed sensor 4 and a coil diameter detector are installed on the winding roller 3, and the coil diameter detector detects the coil diameter of the winding roller 3; The control terminal is connected with the rotational speed sensor 4 and the roll diameter detector. The roll diameter detector in this embodiment adopts the encoder commonly used in the prior art. The encoder is connected to the PLC control terminal to detect the number of turns of the reel, and then according to the thickness of the coil, the real-time roll of the reel can be calculated. Diameter, the specific formula is R=2dC+D, where R is the roll diameter, d is the thickness of the coil, C is the number of...

Embodiment 2

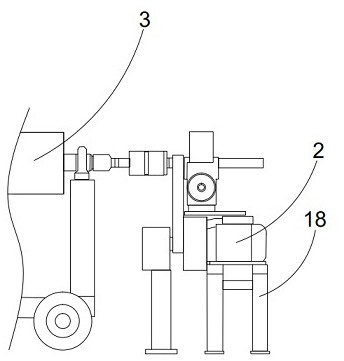

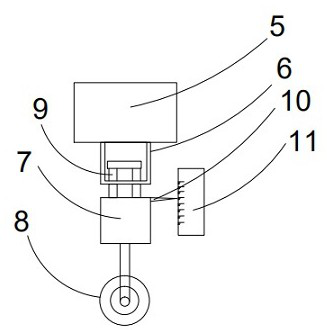

[0028] Such as figure 1 , 3 As shown, a high-speed winding machine reel speed regulating device includes a frame 1 and a motor 2, a winding roller 3 is rotated on the frame 1, and the central axis of the winding roller 3 is connected to the output end of the motor 2, It is characterized in that: a rotational speed sensor 4 and a coil diameter detector are installed on the winding roller 3, and the coil diameter detector detects the coil diameter of the winding roller 3; The control terminal is connected with the rotational speed sensor 4 and the roll diameter detector. In this embodiment, the roll diameter detector includes a fixed plate 5 fixed on the top of the winding roller 3, the bottom of the fixed plate 5 is connected with a fixed frame 6, the inside of the fixed frame 6 is provided with a movable cavity and the bottom is provided with a guide hole, the fixed frame The bottom of the 6 is provided with a lifting block 7, the bottom of the lifting block 7 is connected w...

Embodiment 3

[0030] Such as Figure 1-6In this embodiment, the motor 2 and the speed change device are improved. The motor is supported by the motor base 18, and is connected with the middle shaft of the winding roller through the speed change device. Specifically, the speed change device includes a shaft sleeve 20, a magnetic steel 21, a special Bearing and belt pulley 23, output shaft 19 is sleeved with axle sleeve 20, and axle sleeve 20 is provided with magnetic steel 21, and the rear end of axle sleeve 20 is connected with special bearing, and the rear end of characteristic bearing 22 is connected with electric telescopic rod 32, A section of the output shaft 19 away from the motor 2 is connected with a belt pulley 23, the belt pulley 23 is connected to a transmission joint through a belt, and the transmission joint is connected to the central axis of the winding roller 3, and the characteristic bearing includes an inner ring 24 and an outer ring 25, A roller 26 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com