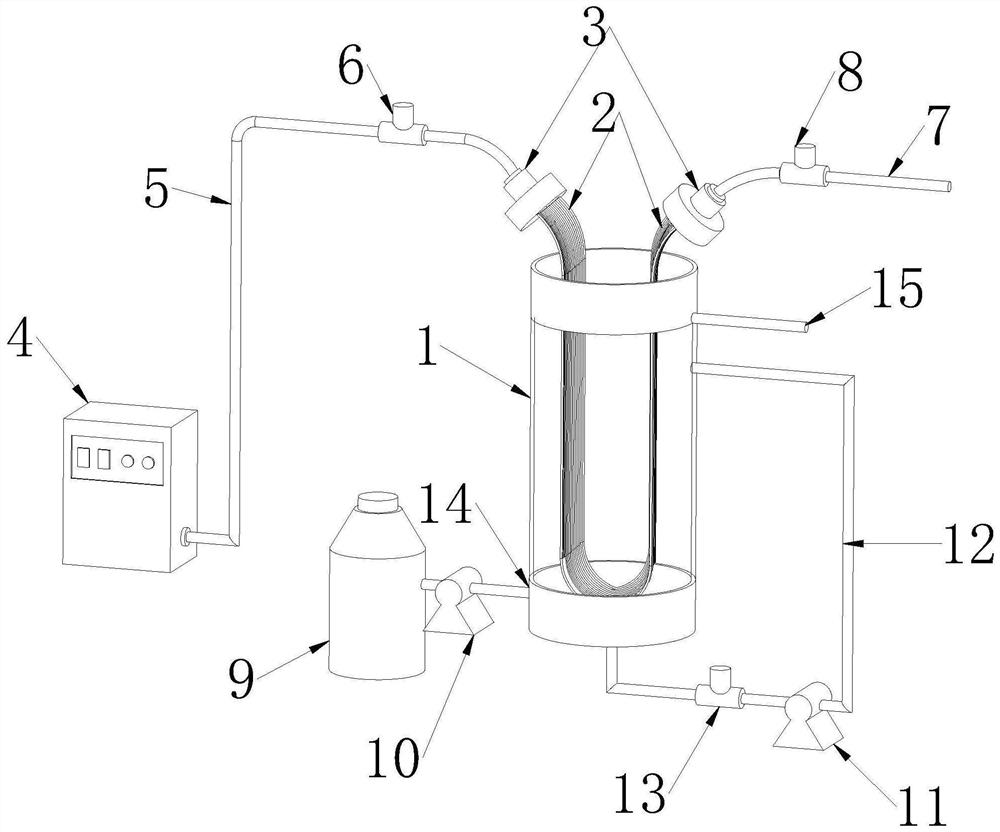

Denitrification nitrogen and phosphorus removal sewage treatment system and treatment method

A sewage treatment system, nitrification and denitrification technology, applied in the field of sewage treatment, can solve the problems of high process energy consumption, high treatment cost, large floor area, etc., achieve simplified biological denitrification and phosphorus removal process, low sludge output, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Put 1.6m long and 150 hollow fiber membrane modules in the container, close the air outlet regulating valve, open the circulation pump and air compressor; add the activated sludge from the urban sewage treatment plant to the MABR In the container of the device, there is no membrane silk, and the nitrate 30-50mg / L, the phosphorus source 10-50mg / L and the carbon source 150-300mg / L are regularly added to provide nutrients for the activated sludge for 30 days. Let the microorganisms be loaded on the surface of the membrane filament; then adjust to continuously flow in water according to the above method, and carry out acclimatization and enrichment, wherein, ORP, pH and dissolved oxygen probes are used to monitor from the upper opening of the container, and the ORP is -40--1mV. , increase the load, and strengthen the function. The effluent quality is obtained from the effluent quality test at the outlet. The result is that the total nitrogen removal rate is 99.8%,...

Embodiment 2

[0036]Embodiment 2: Put two groups of above-mentioned membrane components in the container; Process according to the above-mentioned steps, continue for three weeks, adjust to continuously flow into the water, increase the load, and increase the hydraulic retention time to 2.6d, the result is a total nitrogen removal rate of 100 %, the removal rate of organic matter is 91.4%, and the removal rate of total phosphorus is 80.1%, which reduces the start-up time of phosphorus removal.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap