A method for regulating and purifying and separating chromium mineralization in chromium-containing waste liquid

A technology for purification and separation of waste liquid, applied in the field of chemical separation, can solve the problems of poor chromium precipitation rate, poor product utilization, low ore-forming rate, etc., to achieve enhanced chromium-precipitation rate, significant economic benefits, and increased ore-forming rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

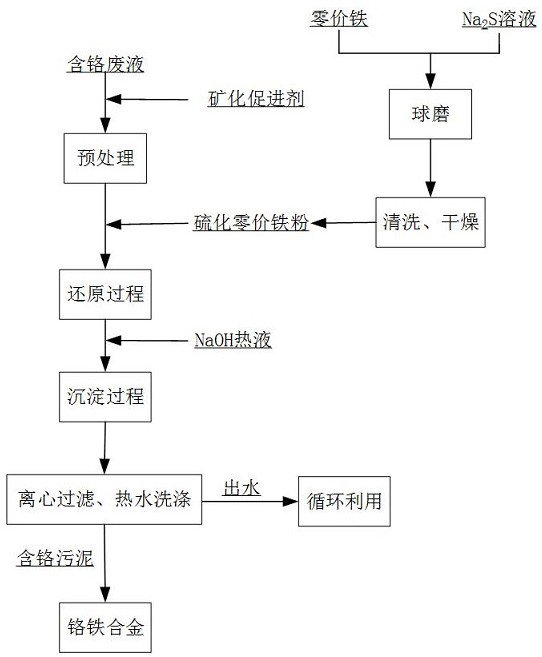

[0065] A method for regulating and purifying and separating chromium mineralization in chromium-containing waste liquid, comprising:

[0066] 1. Take the chromium-containing waste liquid from the iron and steel smelter for use. The main chemical components of the chromium-containing waste liquid are shown in the following table:

[0067] element total chromium Hexavalent chromium P Si Zn S Na Content (mg / L) 5324.10 3625.0 1412.40 1159.00 578.34 322.13 128.09

[0068] 2. First, add 20 g of zero-valent iron powder and 250 mL of 40 g / L Na 2 S solution, reacted at a ball milling speed of 300 r / min for 1 h, and then washed with deoxygenated water; the modified zero-valent iron sulfide powder washed with deoxygenated water was collected under the action of an external magnetic field, and then placed in a vacuum oven at 105 °C Dry for 2 h, and store in a vacuum seal after drying to prevent oxidation.

[0069] 3. Take 25mL of the above-mentioned c...

Embodiment 2

[0074] A method for regulating and purifying and separating chromium mineralization in chromium-containing waste liquid, comprising:

[0075] 1. Take the chromium-containing waste liquid from the iron and steel smelter for use. The main chemical components of the chromium-containing waste liquid are shown in the following table:

[0076] element total chromium Hexavalent chromium P Si Zn S Na Content (mg / L) 5324.10 3625.0 1412.40 1159.00 578.34 322.13 128.09

[0077] 2. First, add 20 g of zero-valent iron powder and 250 mL of 40 g / L Na 2 S solution, reacted at a ball milling speed of 300 r / min for 1 h, and then washed with deoxygenated water; the modified zero-valent iron sulfide powder washed with deoxygenated water was collected under the action of an external magnetic field, and then placed in a vacuum oven at 105 °C Dry for 2 h, and store in a vacuum seal after drying to prevent oxidation.

[0078] 3. Take 25mL of the above-mentioned...

Embodiment 3

[0083] A method for regulating and purifying and separating chromium mineralization in chromium-containing waste liquid, comprising:

[0084] 1. Take the chromium-containing waste liquid from the iron and steel smelter for use. The main chemical components of the chromium-containing waste liquid are shown in the following table:

[0085] element total chromium Hexavalent chromium P Si Zn S Na Content (mg / L) 5324.10 3625.0 1412.40 1159.00 578.34 322.13 128.09

[0086] 2. First, add 20 g of zero-valent iron powder and 250 mL of 40 g / L Na 2 S solution, reacted at a ball milling speed of 300 r / min for 1 h, and then washed with deoxygenated water; the modified zero-valent iron sulfide powder washed with deoxygenated water was collected under the action of an external magnetic field, and then placed in a vacuum oven at 105 °C Dry for 2 h, and store in a vacuum seal after drying to prevent oxidation.

[0087] 3. Take 25mL of the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com