Plastic bouncing core

A springing core and plastic technology, which is applied in the field of plastic springing cores, can solve problems such as difficult cleaning, affecting the service life of the product, and inability to reset smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

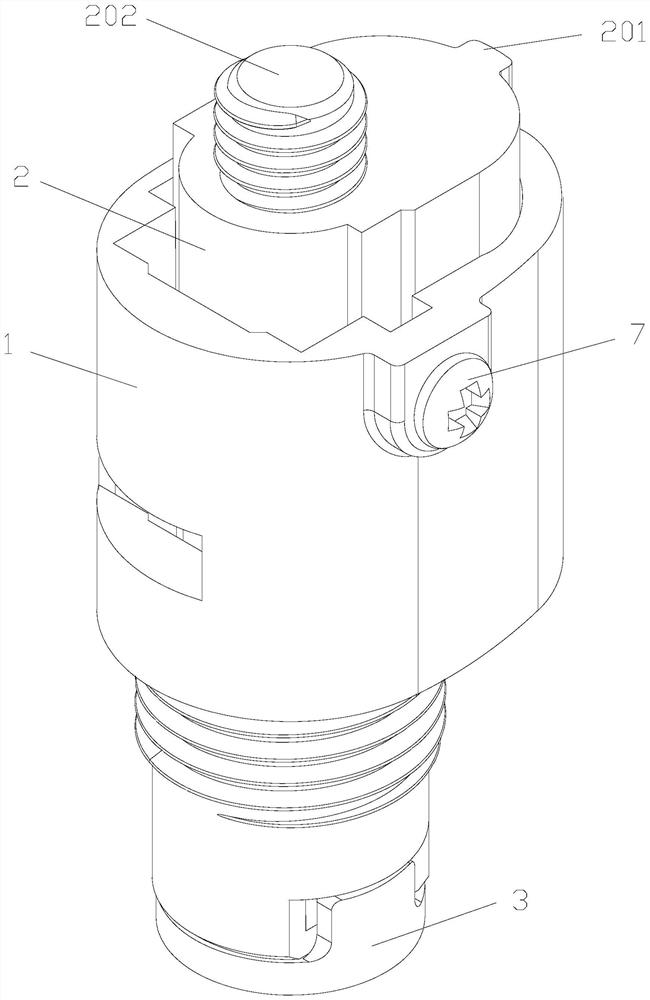

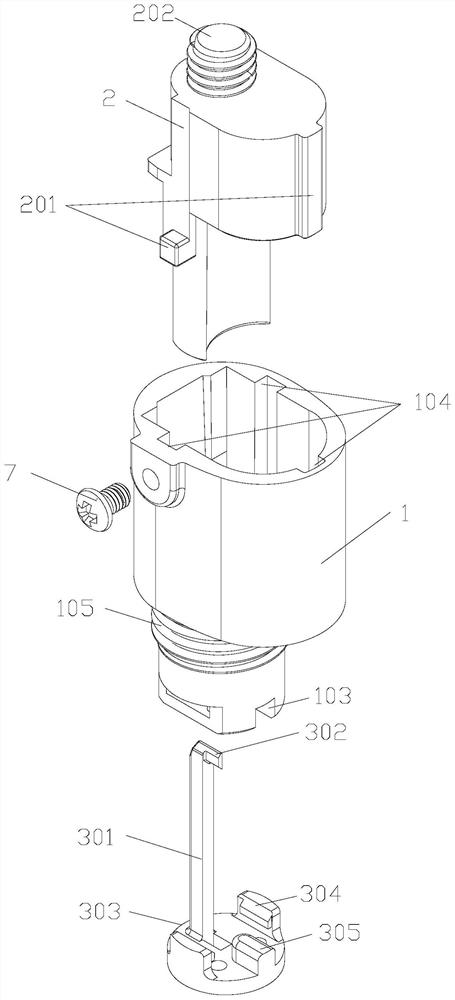

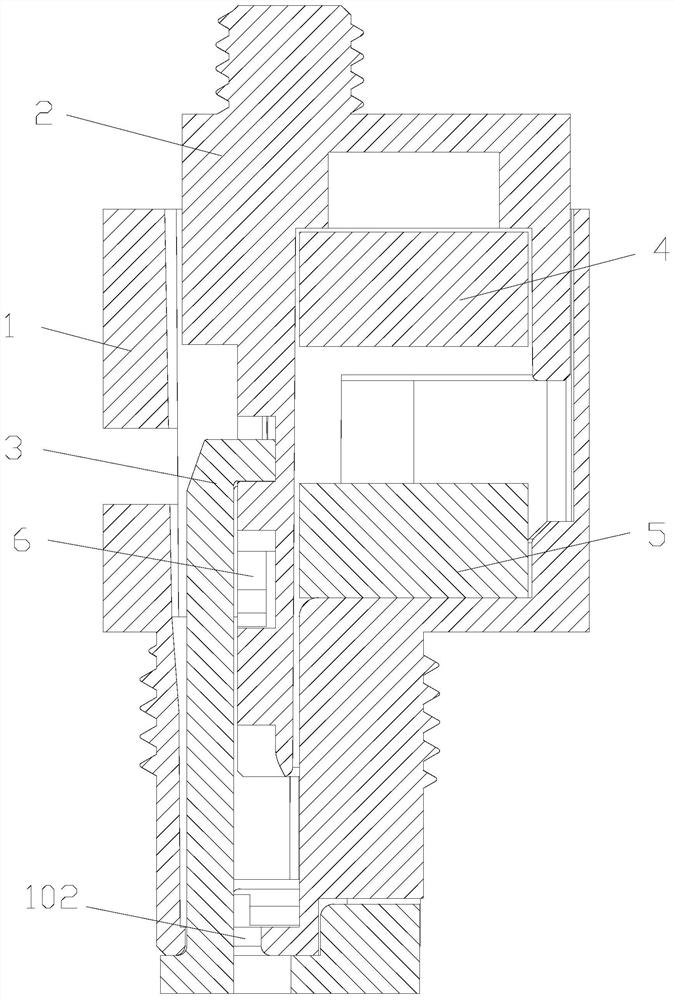

[0029] Specific examples: such as Figure 1-8 As shown, this embodiment provides a plastic springing core, including a shell 1, a springing inner core 2, a plastic elastic bone 3, and a magnetic rebound mechanism. The magnetic rebound mechanism is located in the shell 1 and is located below the bouncing inner core 2 to drive the bouncing inner core 2 to move upwards to open or close the water outlet. The side wall of the bouncing inner core 2 is provided with a limit track groove 6, so One end of the plastic elastic bone 3 is slidably installed in the limit track groove 6 and cooperates with the limit track groove 6 so that the bouncing inner core 2 is in an open or closed state, and the other end of the plastic elastic bone 3 is movable under the shell 1 and is connected to the shell 1. The limit fit of the lower end face prevents the plastic elastic bone 3 from popping out of the shell 1 upwards.

[0030] In this embodiment, in order to realize the bouncing reset after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com