Oil reservoir protector and application of oil reservoir protector in risk well of oil production engineering

A technology of protector and oil layer, which is applied in the direction of wellbore/well valve device, drilling equipment, earthwork drilling and production, etc., and can solve problems such as blowout, economic loss, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

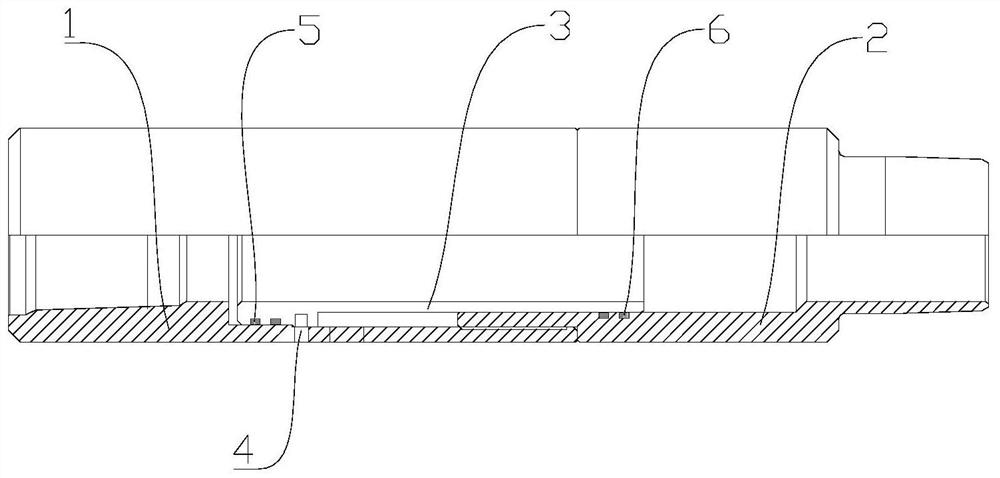

[0031] Please refer to figure 1 shown. This embodiment provides an oil layer protector, which includes an upper joint 1, a constant pressure sliding sleeve 3 and a lower joint 2. The upper joint 1 and the lower joint 2 are connected to form a cavity, and the constant pressure sliding sleeve 3 is located in the cavity. The upper joint 1 is provided with a first oil drain through hole for communicating with the cavity, the lower joint 2 is provided with a second oil drain through hole for communicating with the cavity, and the upper joint 1 is provided with a hole for the constant pressure sliding sleeve 3 to discharge the first oil drain The stopper for blocking the oil through hole and the second oil drain through hole.

[0032]In the above embodiment, an oil layer protector is composed of an upper joint 1, a constant pressure sliding sleeve 3 and a lower joint 2, wherein the upper joint 1 and the lower joint 2 are connected to form a cavity, and the constant pressure sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com