Power transmission line equipment defect detection method based on sample offset network

A transmission line and defect detection technology, applied in the field of image data processing and neural network, can solve problems such as high risk, high level of professional requirements, and easy to be affected by personal experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] The present invention obtains the defect detection model of transmission line equipment based on the preset training set and deep learning structure training, and can detect six types of defects, including bird's nest, insulator self-explosion, shockproof hammer damage, tower foundation burial, tower foundation soaking, and bird baffle damage detection.

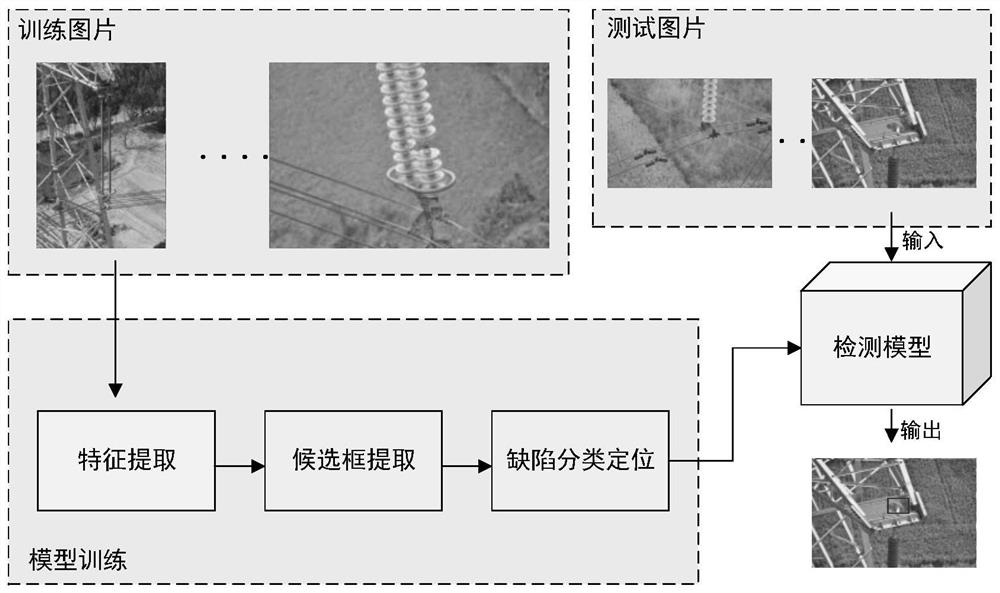

[0063] figure 1 The above is the overall architecture diagram of defect detection. After image preprocessing, the collected image data is input to the convolutional neural network model for model training. The network is divided into three parts: feature extraction, candidate frame extraction and positioning classification. After multiple iterations , the network parameters are optimized, and finally the trained convolutional neural network model is obtained. The test set images are input into the trained convolutional neural network model for testing, and the overall performance of the convolutional neural network mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com