Red date pitting equipment for making donkey-hide gelatin dates

A technology of Ejiao date and nuclear equipment, which is applied in the direction of fruit de-pitting device, application, fixed filter element, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

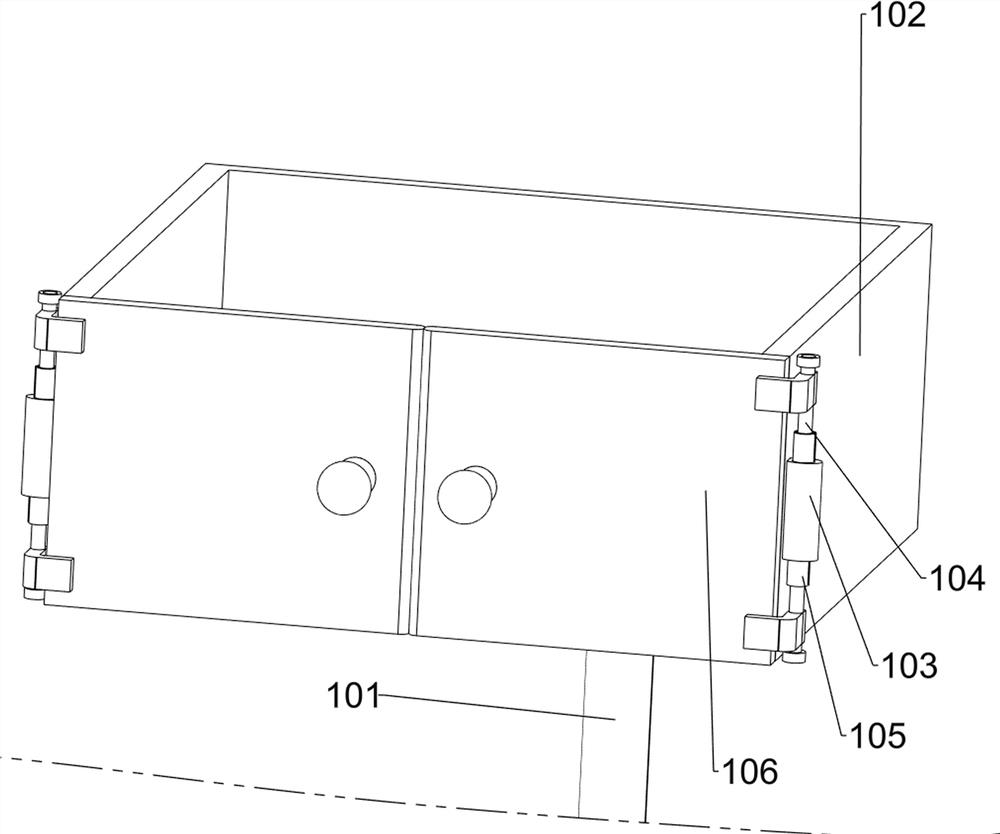

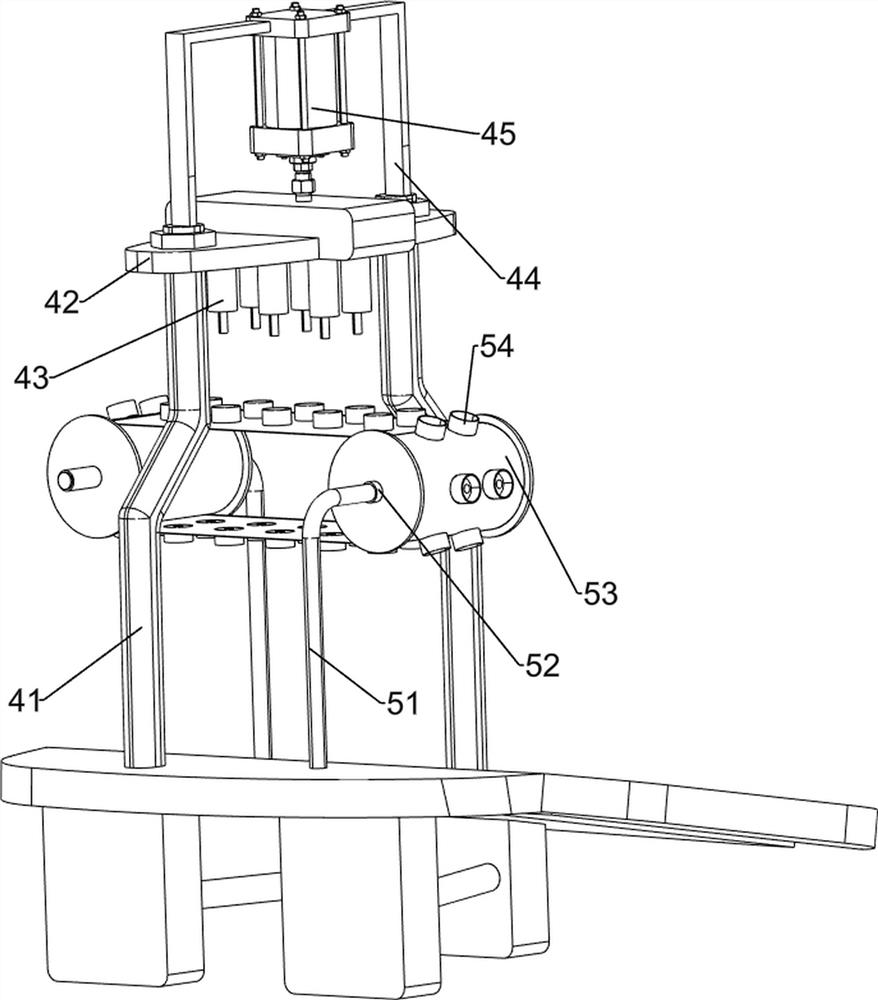

[0034] A kind of donkey-hide gelatin jujube is made red jujube pitting equipment, such as Figure 1-2 As shown, it includes a frame 1, a mounting plate 2, a sloping plate 3, a nuclear removal mechanism 4 and a transmission mechanism 5, the top of the frame 1 is connected with the mounting plate 2, the rear side of the mounting plate 2 is connected with a slanting plate 3, and the sloping plate 3 The bottom is connected to the top of the frame 1, and the top of the mounting plate 2 and the top of the inclined plate 3 are respectively provided with a denuclearization mechanism 4 and a transmission mechanism 5.

[0035] Nucleation mechanism 4 includes special-shaped support rod 41, lower pressing block 42, nuclear removal rod 43, support 44 and cylinder 45, and mounting plate 2 top front side and inclined plate 3 top rear sides are all connected with special-shaped support rod 41, two A lower pressing block 42 is slidably connected between the special-shaped poles 41, three rows ...

Embodiment 2

[0039] On the basis of Example 1, such as figure 1 and image 3 As shown, a linkage mechanism 6 is also included, and the linkage mechanism 6 includes a connecting frame 60, a ratchet 61, a support plate 62, a first rotating shaft 63, a ratchet 64, a second pulley set 65, an opposing gear set 66, a second rotation Rod 67, the third pulley group 68 and the second rotating shaft 69, the bottom front side of the lower pressure block 42 is connected with a connecting frame 60, the connecting frame 60 is slidably connected with a ratchet 61, and the ratchet 61 and the connecting frame 60 are connected with a Two elastic parts, the left side of the top of the mounting plate 2 is connected with a support plate 62, the upper part of the support plate 62 is rotatably connected with a first rotating shaft 63, the first rotating shaft 63 is connected with a ratchet 64, the ratchet 64 cooperates with the ratchet 61, and the support plate The bottom of the 62 is rotatably connected with a...

Embodiment 3

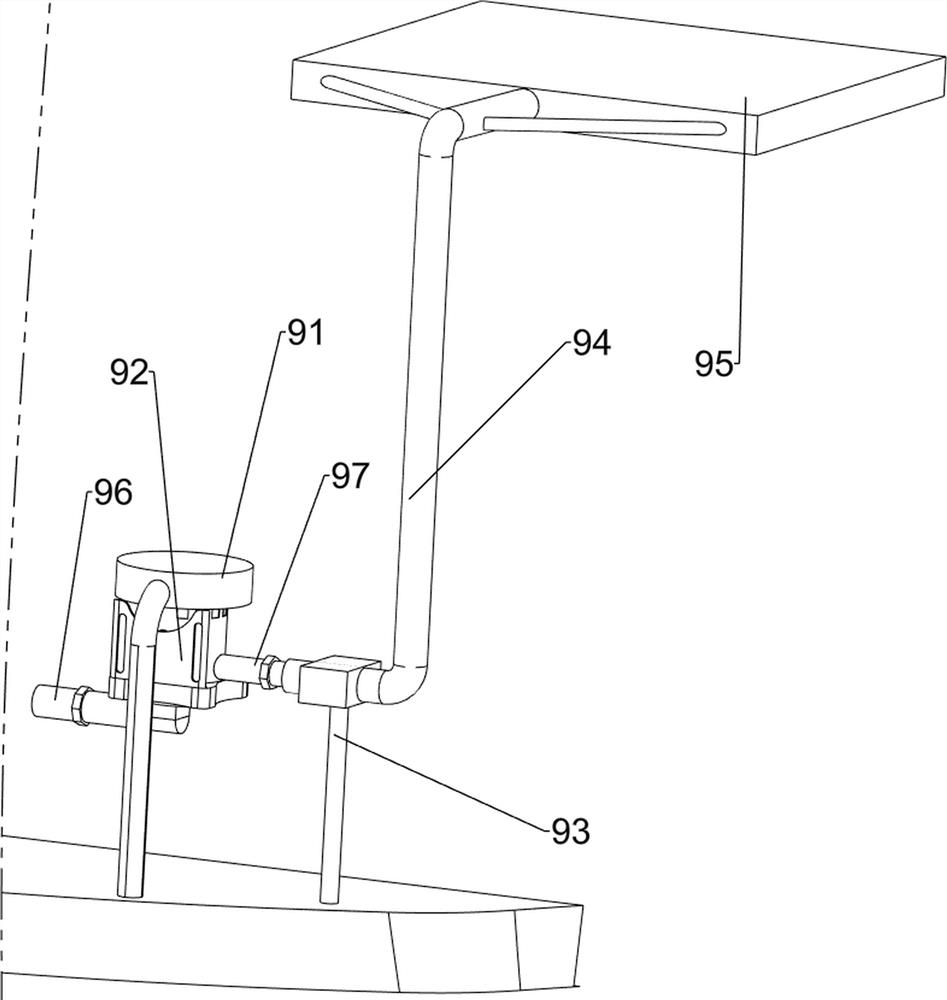

[0042] On the basis of Example 2, such as figure 1 and Figure 4 As shown, cleaning mechanism 7 is also included, and cleaning mechanism 7 includes connecting rod 71, guide plate 72, rack 73, cleaning rod 74, transmission gear set 75, support frame 76, cleaning frame 77 and discharge pipe 78, and the following The front side of the right side of the briquetting block 42 is connected with a connecting rod 71, the rear side of the top of the mounting plate 2 is connected with a guide plate 72, the guide plate 72 is slidably connected with a rack 73, the rack 73 is fixedly connected with the connecting rod 71, and the inclined plate 3 The top right front side is connected with a support frame 76, the top of the support frame 76 is connected with a cleaning frame 77, the middle of the bottom of the cleaning frame 77 is connected with a discharge pipe 78, and the cleaning frame 77 is symmetrically connected with two cleaning rods 74, two cleaning rods 74 is connected with transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com