Welding mask assembly and lamp assembly thereof

A technology for welding masks and components, which is applied to eye masks, components of lighting devices, lighting devices, etc., and can solve the problems of inconvenient flashlight irradiation and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

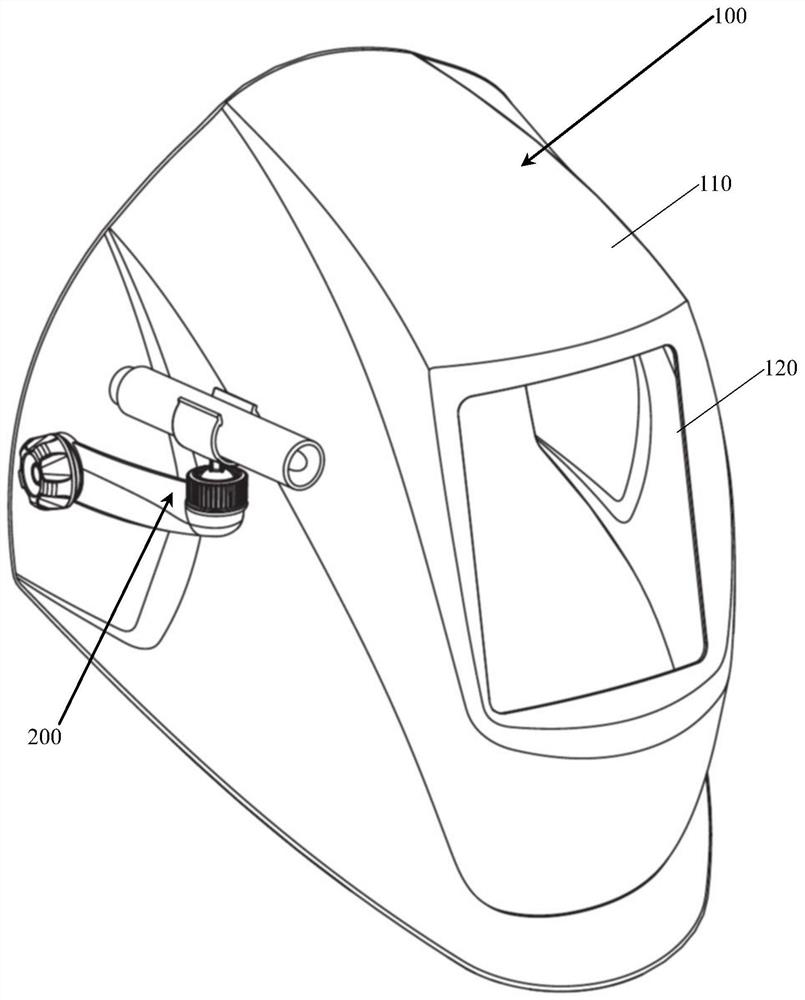

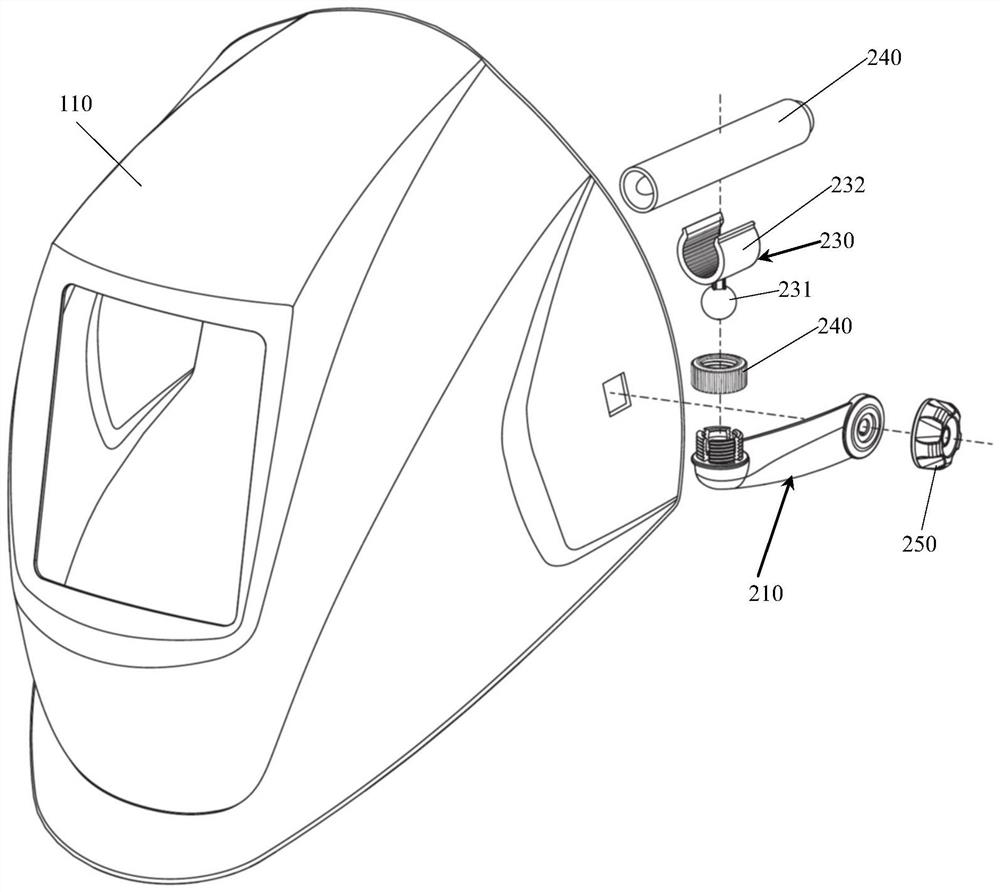

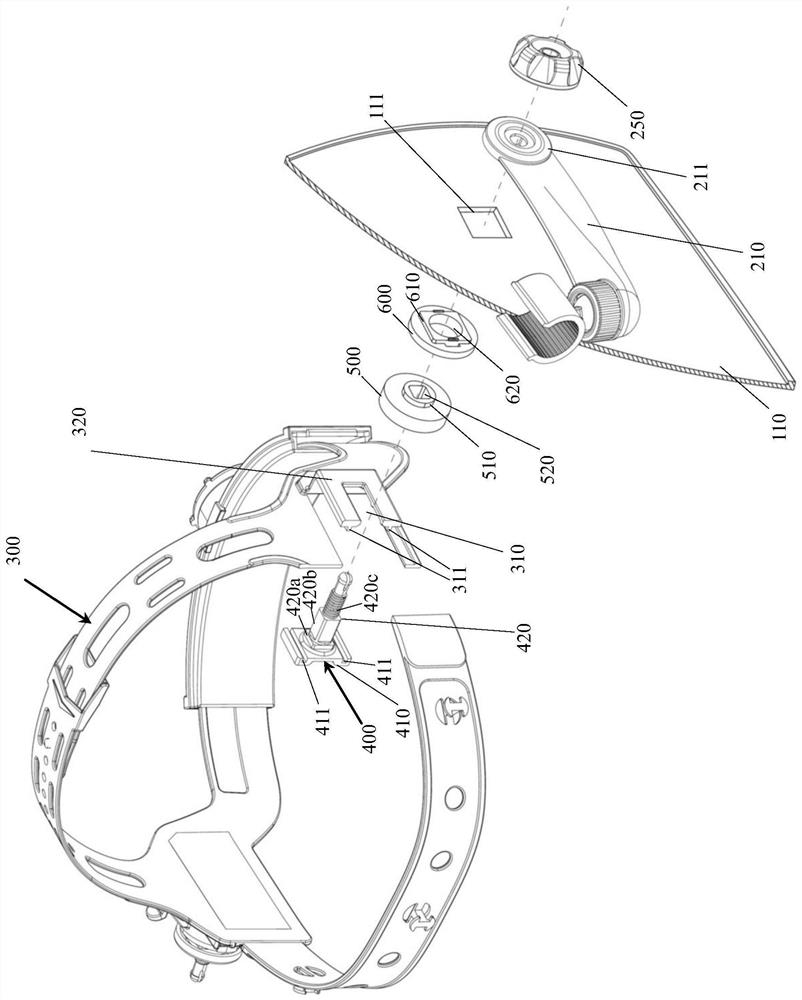

[0055] figure 1 A welding helmet 100 is schematically shown, on which a lamp assembly 200 according to an embodiment of the present application is mounted. It should be noted that the welding helmet 100 can be removably mounted on figure 1 The headgear structure (see figure 2 ). The headband structure can be fixed on the user's head. The welding helmet 100 is pivotable about a particular pivot axis relative to the headgear structure. According to the technical solution of the present application, there may be one or two lamp assemblies 200 . In the case of one lamp assembly 200 , the lamp assembly 200 may be installed on the left side or the right side of the welding helmet 100 . In the case of two lamp assemblies 200 , the lamp assemblies 200 may be respectively installed on the left side and the right side of the wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com