Anti-loose buckle for roll core of steel roll

A steel coil and coil core technology, applied in the field of inner coil clamping tools, can solve problems such as the influence of steel coil on coiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

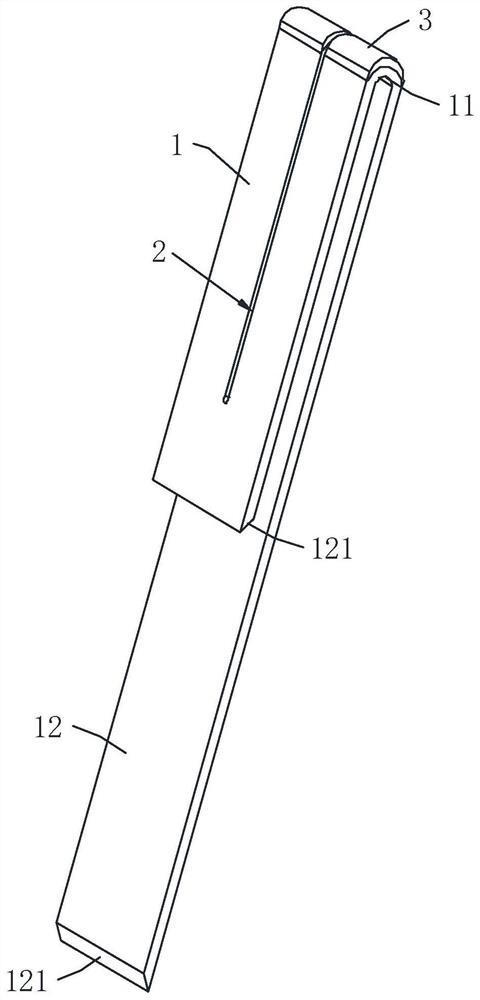

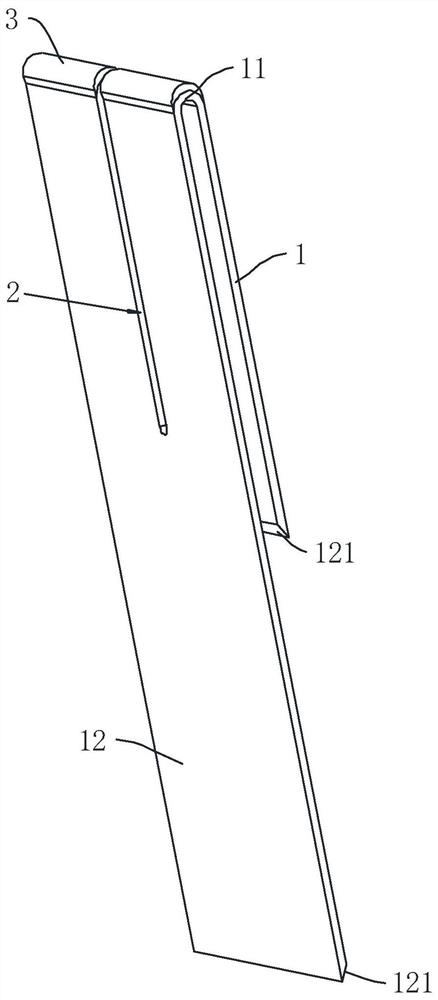

[0022] A steel coil core anti-loosening buckle, refer to Figure 1-2 , including a clamping body 1, the clamping body 1 is a strip-shaped steel plate, the clamping body 1 can be made of steel such as spring steel or EXT800, and the clamping body 1 is made of spring steel here.

[0023] The middle part of the clamping body 1 is bent in a "U" shape along the direction perpendicular to its length to form a bent part 11 . When it is necessary to roll up the steel coil with a loose core, insert and clamp multiple buckles on the 2-3 layers inside the steel coil. Here, two buckles are used to clamp and fix the coil core of the steel coil, one of which is clamped and fixed at a distance of 50 cm from the end of the steel coil coil core, and the other is clamped and fixed on the opposite side of the buckle, reducing the The end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com