Iron and steel scrap recovery counterweight production device

A technology for production equipment and scrap iron and steel, which is applied in the direction of presses, manufacturing tools, etc., and can solve the problems of occupying transportation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific implementations.

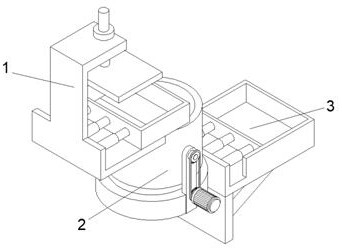

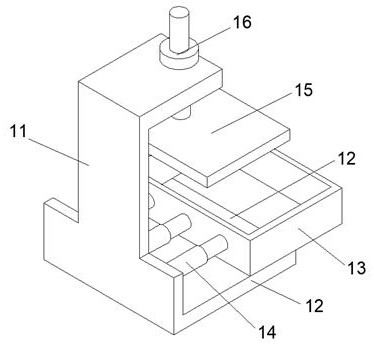

[0015] A scrap iron and steel recycling counterweight production device, comprising a cold stamping machine 1, a hot-melting machine 2, and a hot stamping machine 3, the cold stamping machine 1 is arranged on the front top side of the hot-melting machine 2, and the hot stamping machine 3 It is arranged on the rear bottom side of the hot-melting machine 2 , the rear end of the cold stamping machine 1 is arranged on the top side of the hot-melting machine 2 , and the hot-melting machine 2 is arranged on the front top side of the hot stamping machine 3 .

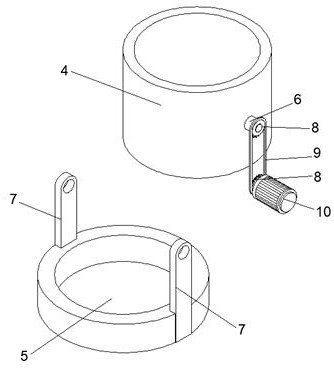

[0016] The hot melt machine 2 is composed of a heating furnace 4, a container pot 5, a side end support shaft 6, a support arm 7, a linkage toothed plate 8, a connecting chain belt 9, and a tipping and turning motor 10. The side end support shaft 6 is provided with Two groups, two groups of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com