Cotton fiber shape compressor

A compressor and cotton fiber technology, applied in the field of cotton fiber testing, can solve the problems of different operation techniques and proficiency, testing errors, long working hours per day, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in the following examples, and the described embodiments are merely, and embodiments are intended to be, in rather than all embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

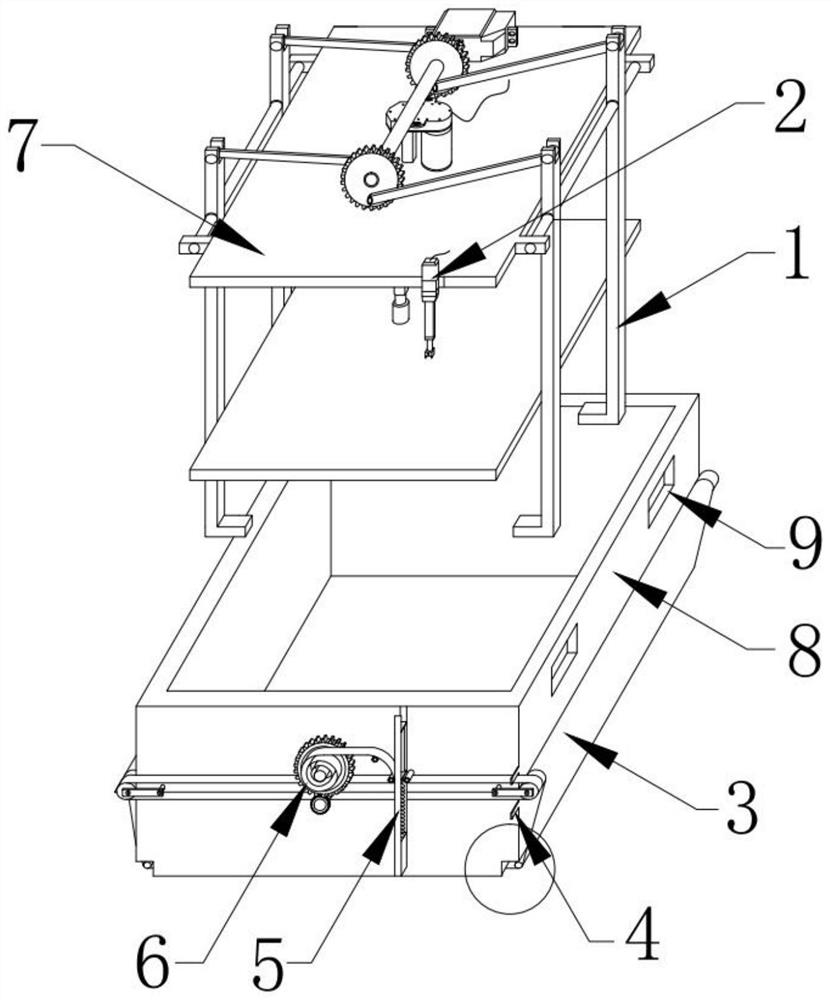

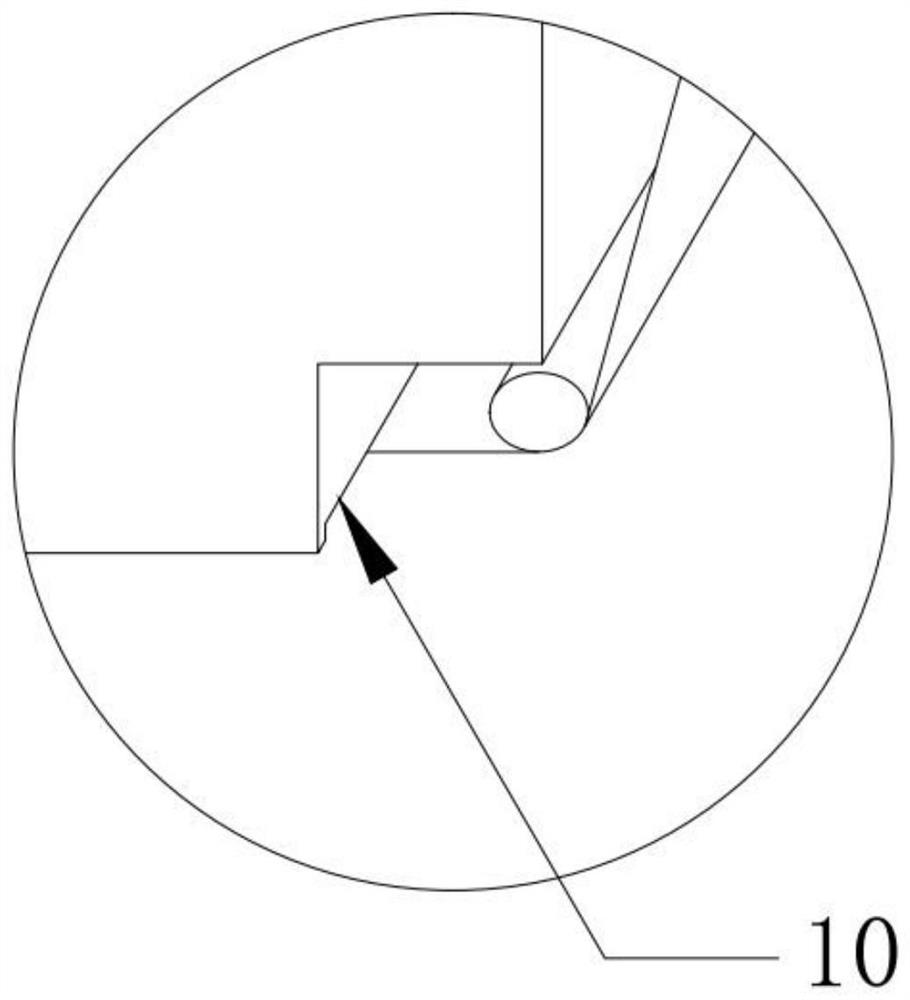

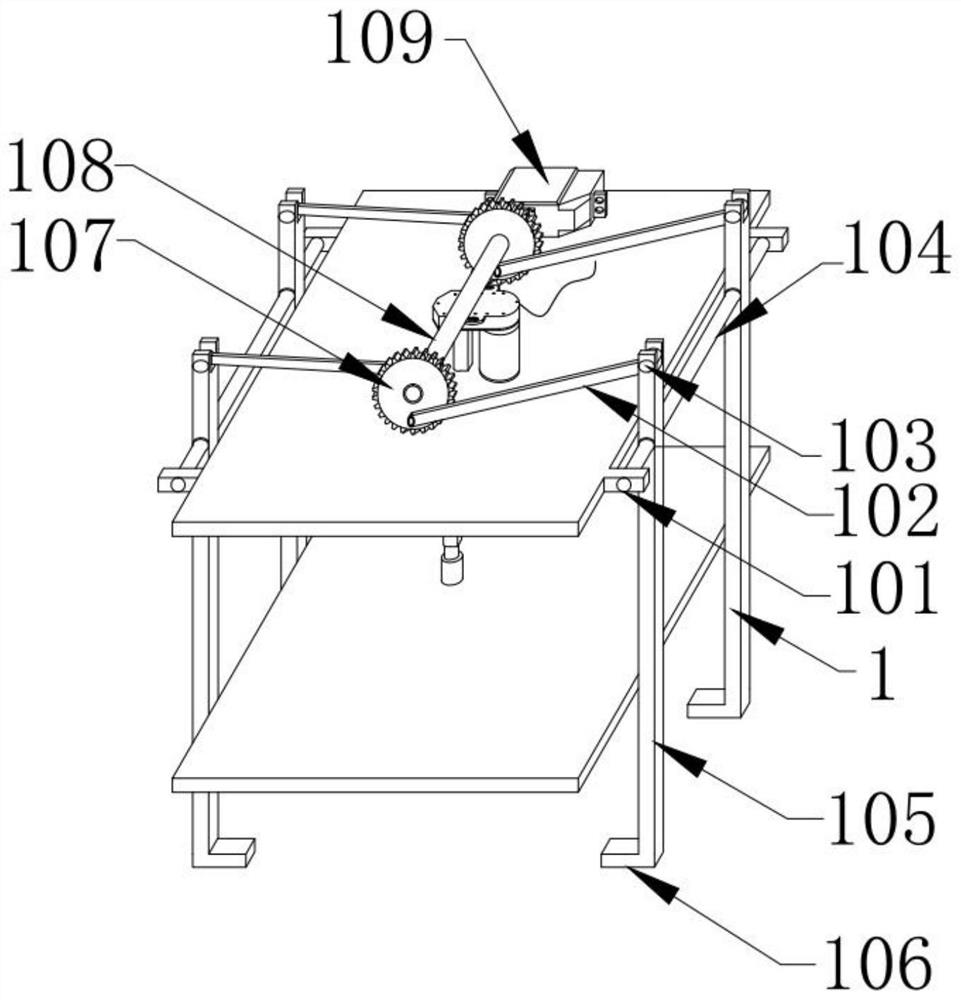

[0031] See Figure 1-3The present invention provides a technical solution: A cotton fiber shape compressor comprising machine claw mechanism 1, the end of the cassette rotation mechanism 3, the compression plate mechanism 7, 8 forming box, the machine 1 central pawl mechanism disposed centrosymmetric there are four link 105, the link 105 is fixedly connected to a lower gripper 106, the left and right sides of each of the two front link 105 by rotating shaft 104 fixedly connected to the rotating shaft 104 are respectively front and rear ends fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com