Height limiting early warning device for transport vehicle

A technology of an early warning device and a transport vehicle, which is applied in the field of transportation, can solve the problems of inability to trigger the normally closed sensor switch, inability to avoid the height limit device in advance, and difficulty in measuring the height of the highest point of the goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

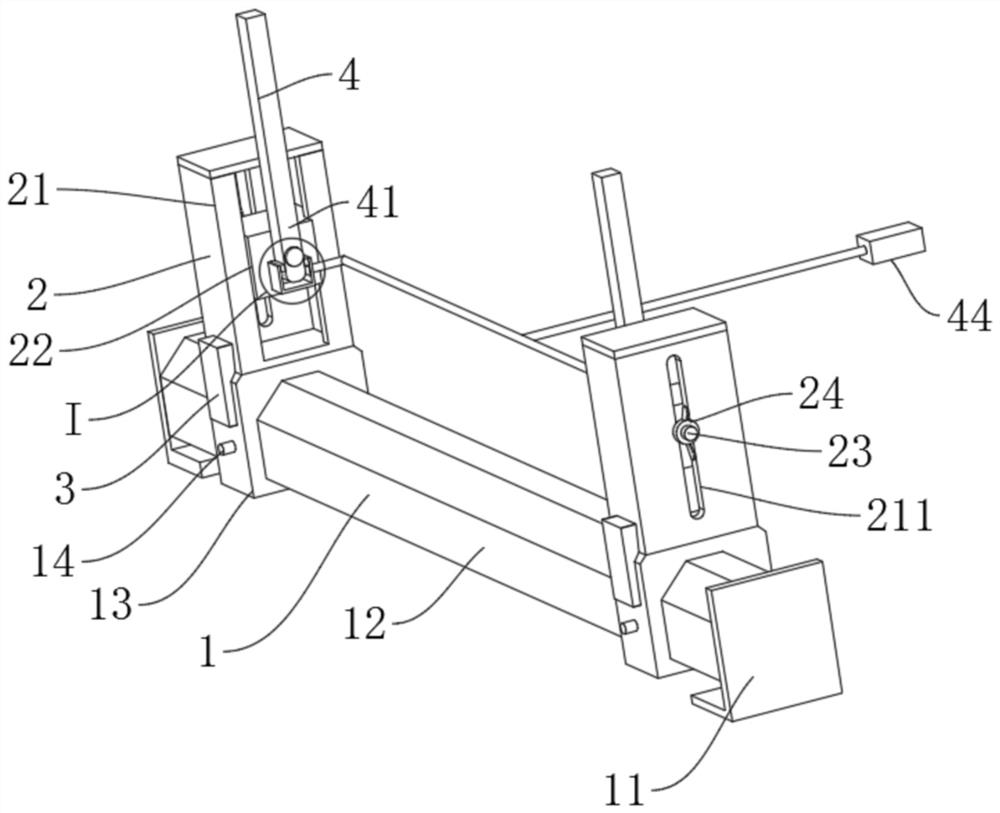

[0031] Embodiment one, such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a height limit early warning device for a transport vehicle includes a horizontal slide rail pair 1, a vertical slide rail pair 2, an early warning assembly 4 installed on the top of the front of the transport vehicle and arranged in parallel along the width direction of the transport vehicle, and a horizontal slide rail pair The top of the mobile end of 1 is provided with a vertical slide rail pair 2, and the side of the mobile end of the vertical slide rail pair 2 facing the moving direction of the horizontal slide rail pair 1 is provided with an early warning component 4, so that the setting can pass through the horizontal slide rail Vice 1 adjusts the position of early warning assembly 4, and adjusts the height of early warning assembly 4 by vertical slide rail pair 2;

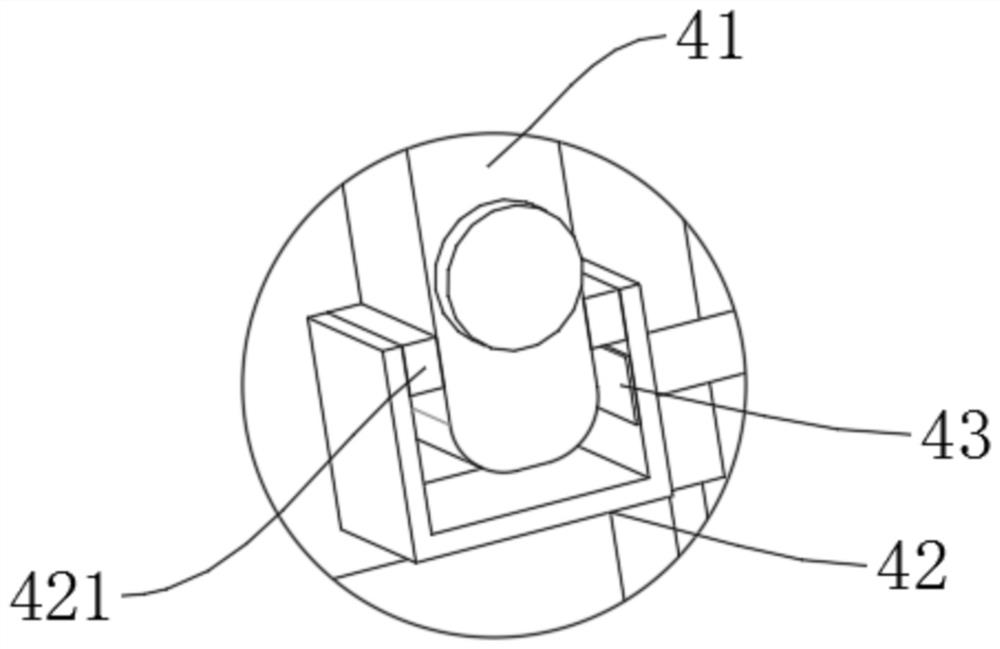

[0032] The early warning assembly 4 includes a warning pole 41, a U-shaped seat 42, a trigger switch 43, and an al...

Embodiment 2

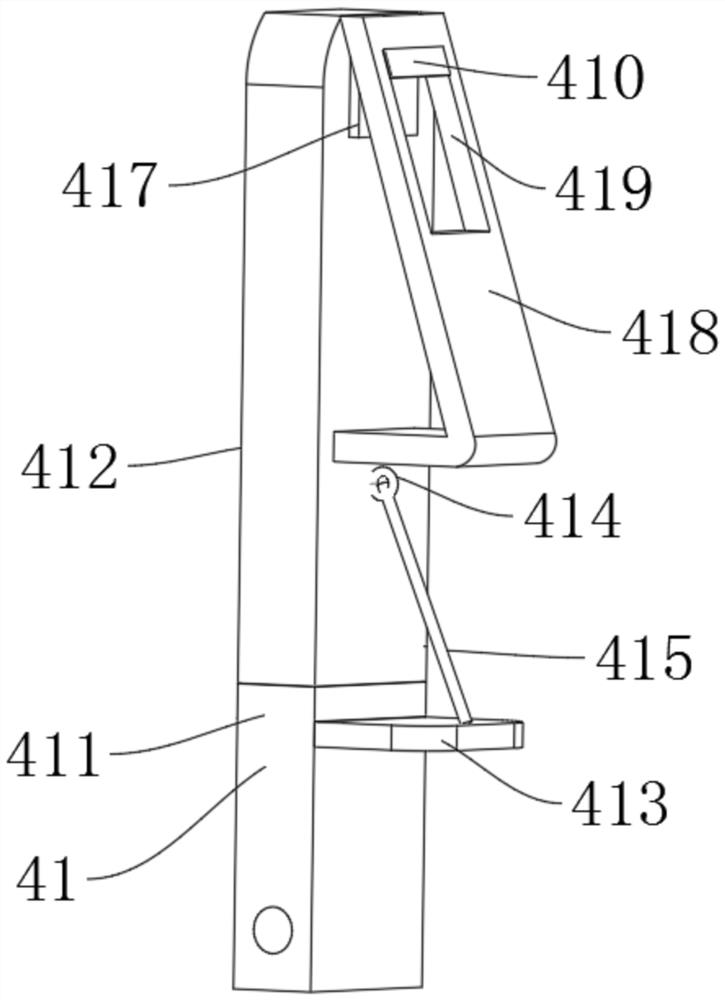

[0034] Embodiment two, on the basis of embodiment one, such as image 3 , Figure 4 As shown, the warning bar 41 includes a trigger bar 411 and an extension bar 412. The side of the top of the trigger bar 411 facing the compartment is connected with a coaxial extension bar 412 through a hinge, and the upper half of the other side of the trigger bar 411 is provided with a mounting plate. 413, a tension spring 415 is arranged between the installation plate 413 and the extension rod 412, and the top of the installation plate 413 and the side of the extension rod 412 are welded with pull rings 414, and the two ends of the extension spring 415 are respectively hung on the two pull rings 414 In this way, when the upper end of the extension rod 412 is blocked, the extension rod 412 drives the trigger rod 411 to rotate, and the lower end of the trigger rod 411 squeezes the trigger switch 43. After reaching a certain level, the transport vehicle fails to brake in time, and the tension ...

Embodiment 3

[0035] Embodiment three, on the basis of embodiment one or two, such as image 3 As shown, the side opposite to the laser generator 416 at the upper end of the early warning pole 41 is equipped with a camera 417 horizontally facing the front of the transport vehicle, so that the situation of the height limiting device can be observed through the camera 417, so that the driver can make a preliminary judgment, and also Whether the tension spring 415 is damaged or separated from the pull ring 414 can be judged by observing the picture transmitted by the camera 417 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com