A kind of preparation method of cellulose-based radiation temperature regulating material

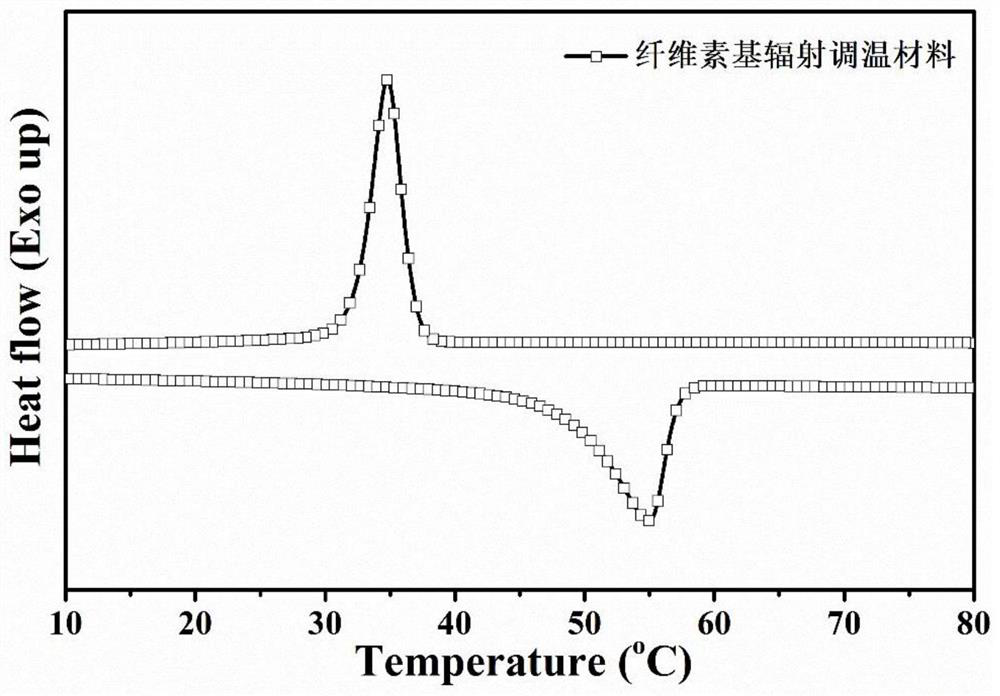

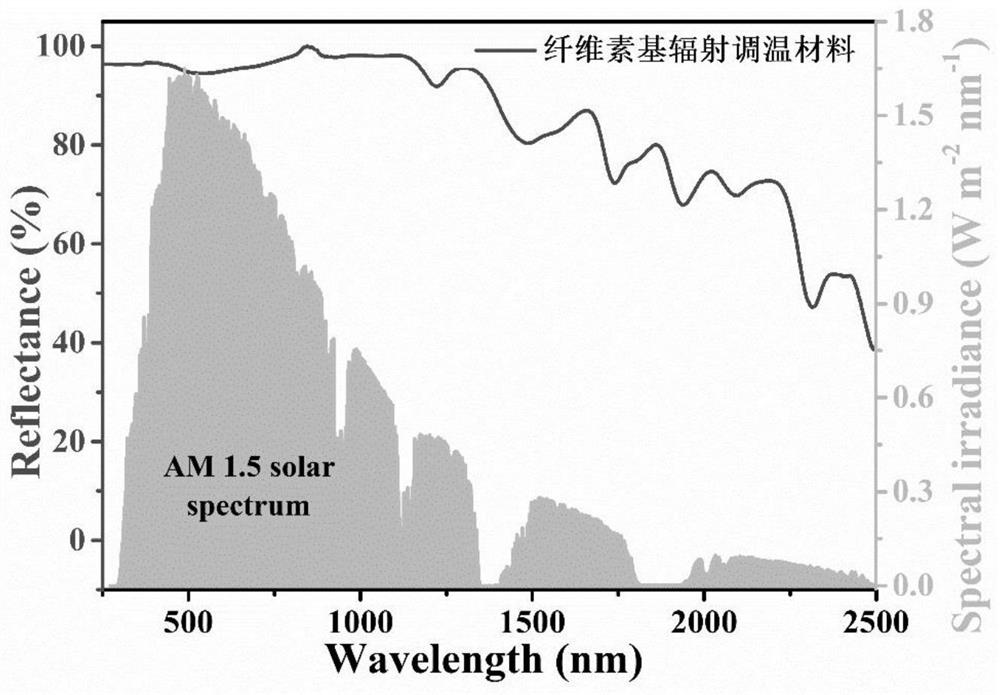

A cellulose-based and cellulose-based technology is applied in the field of preparation of cellulose-based radiation temperature-regulating materials, which can solve the problems of high production cost, unfavorable industrial application, complex and expensive processing equipment, etc., and achieves low raw material and production costs, good biological Effects of degradability and biocompatibility, excellent thermoregulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1 g of commercial microcrystalline cellulose was added to 100 mL of 64% sulfuric acid solution, reacted at 45°C for 45 minutes, the solution was washed to near neutrality by suction filtration and centrifugation, and configured into cellulose nanocrystals with a concentration of 1 wt.% After adding 1 g of sodium periodate and reacting at room temperature for 2 hours, the impurities in the solution were removed by suction filtration and centrifugation, and the dispersion liquid was prepared into an aldehyde-modified cellulose nanocrystal dispersion with a concentration of 0.5 wt.%, and an organic phase change was added. Material Polyethylene glycol, add 0.1g melamine and 0.1g triaminobenzene as cross-linking agent, fully stir and dissolve and adjust the pH of the solution to 2 to obtain cellulose nanocrystal / polyethylene glycol composite hydrogel, which can be obtained after freeze-drying. A cellulose nanocrystal / polyethylene glycol composite material with radiation tempe...

Embodiment 2

[0038] Disperse 1g of manufactured paper into 20ml of aqueous solution by high-pressure homogenization method, remove impurities in the solution by suction filtration and centrifugation and prepare a cellulose dispersion with a concentration of 1wt.%, add 5g of ammonium persulfate, and react at 70°C for 10h Afterwards, impurities in the solution were removed by suction filtration and centrifugation, and the solution was prepared into a carboxylated cellulose dispersion with a concentration of 1 wt.%. 1 g of adipic acid dihydrazide was added to prepare amino-modified cellulose, and impurities in the solution were removed by suction filtration and centrifugation, and the solution was prepared into a dispersion liquid of amino-modified cellulose with a concentration of 10 wt.%. Disperse 1g of filter paper into 20ml of aqueous solution by high-pressure homogenization method, remove impurities in the solution by suction filtration and centrifugation, and prepare a cellulose dispersi...

Embodiment 3

[0040] After adding 2g straw and 20g deionized water to a ball mill at 300 rpm for 10 hours, the solution was washed by suction filtration and centrifugation to remove impurities, and prepared into a cellulose dispersion with a concentration of 1 wt.%. The carboxylated modified cellulose dispersion was prepared by TEMPO oxidation system, 1 g of adipic acid dihydrazide was added to synthesize amino modified cellulose, the impurities in the solution were removed by suction filtration and centrifugation and the concentration was 5wt.% of amino-modified cellulose dispersions. Add 1 mL of glutaraldehyde solution with a concentration of 50%, fully stir and dissolve, and adjust the pH of the solution to 5 to obtain a cellulose hydrogel, which can be freeze-dried to obtain a cellulose aerogel. Cellulose aerogels were impregnated into molten phase change material paraffin to obtain cellulose / paraffin composites with radiation temperature regulation function.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com