Mounting and reinforcing system for cast-in-place structural column formwork between prefabricated vertical wallboards and using method

A technology for structural columns and wall panels, applied in the direction of formwork/formwork members, formwork/formwork/work frame, pillars, etc., can solve the problems of quality and aesthetics, uneven concrete structure, deformation of structural column formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

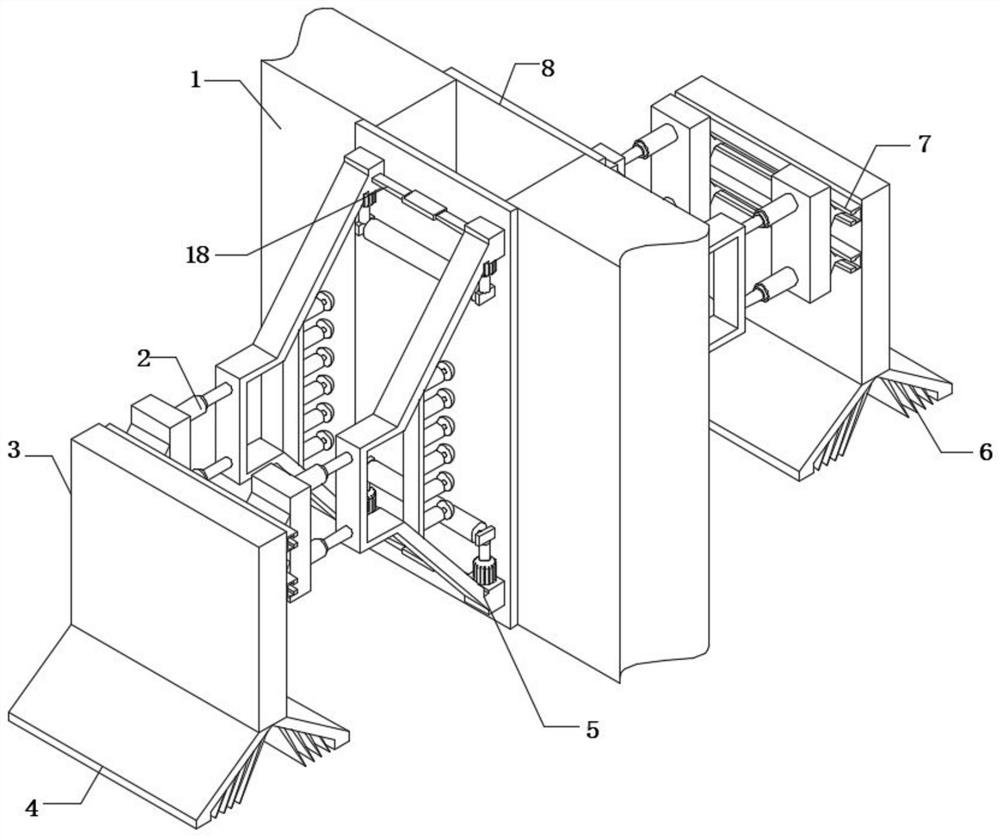

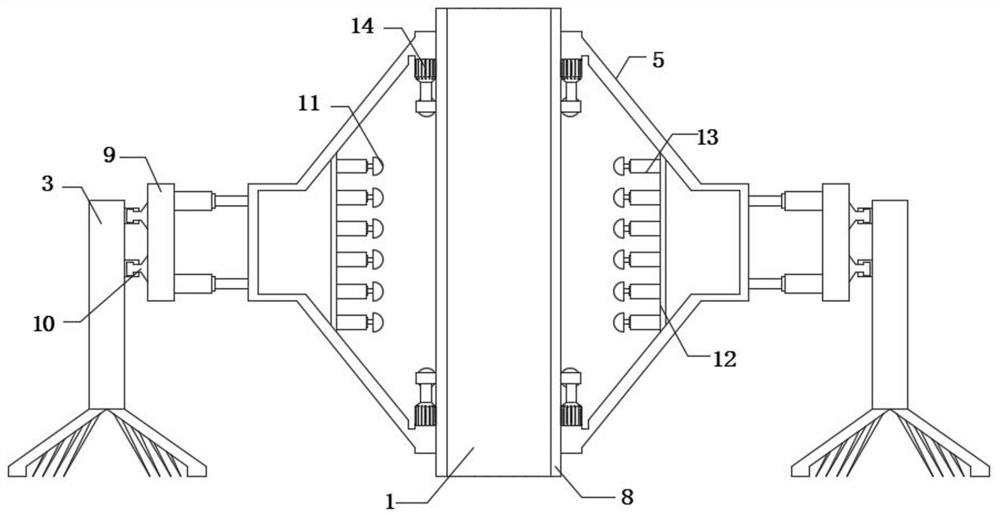

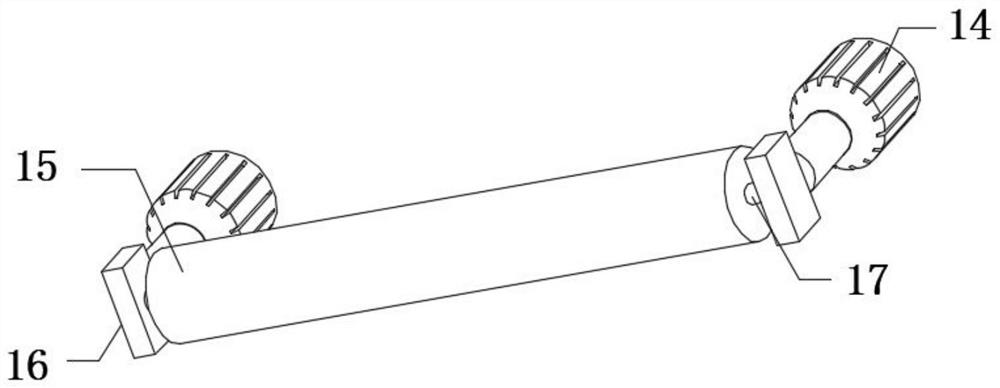

[0025] Embodiment 1: refer to Figure 1-4 , the installation and reinforcement system of the cast-in-place structural column formwork between the prefabricated vertical wall panels, including the wall panel body 1, the installation plate 9 and the fixing plate 3, and the outer wall of each installation plate 9 facing the wall panel body 1 is fixedly connected with the cylinder 2, and The outer walls of the two cylinders 2 on the same mounting plate 9 are fixedly connected with the same spacer 5, and the outer walls of the two spacer frames 5 on one side are fixedly connected with the same reinforcement plate 18 on the opposite side of the outer wall. The outer wall at the top of the frame 5 and the outer wall at the bottom are all fixedly connected with a push rod motor 14, and the output shaft of each push rod motor 14 is fixedly connected with a bearing plate 16, and the opposite sides of two adjacent bearing plates 16 The outer wall is connected with the same connecting sha...

Embodiment 2

[0031] Embodiment 2: The usage method of Embodiment 1, slide the slider 10 on the mounting plate 9 into the slide rail 7 on the fixed plate 3, then move the fixed plate 3 to the outside of the structural column formwork body 8, and adjust the cylinder 2 Drive the limit frame 5 to limit and fix the structural column formwork body 8. During the concrete pouring process, start the push rod motor 14 at the upper and lower ends of the limit frame 5 to drive the squeeze roller 15 to rotate on the connecting shaft 17, and the squeeze roller 15 will rotate on the connecting shaft 17. The structural column formwork body 8 is extruded, and the extrusion and rolling make the deformed position of the structural column formwork body 8 gradually repaired, so as to ensure that the structural column formwork body 8 will not deform the poured concrete due to deformation during the concrete pouring process. After completion, when it is necessary to disassemble the structural column formwork body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com