Setting method for collaborative optimization of desulfurization system and dust removal system of thermal power generating unit

A technology of dust removal system and desulfurization system, which is applied in instruments, data processing applications, forecasting, etc., can solve the problems of large design margin, not considering the synergistic dust removal effect of wet desulfurization system, and high operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

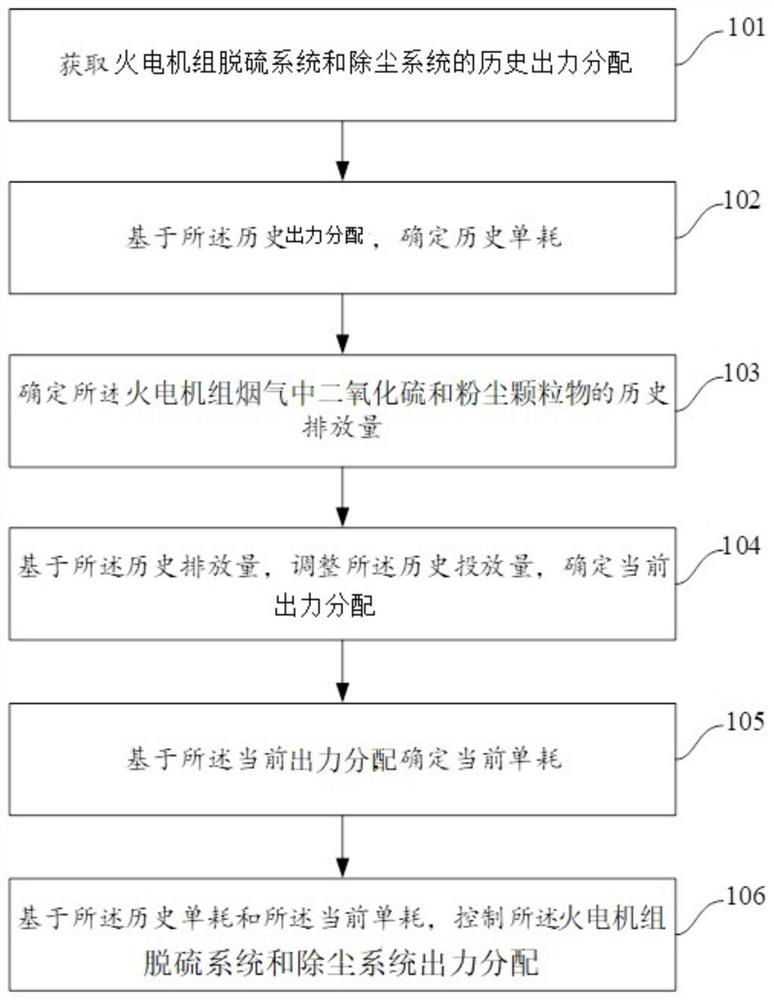

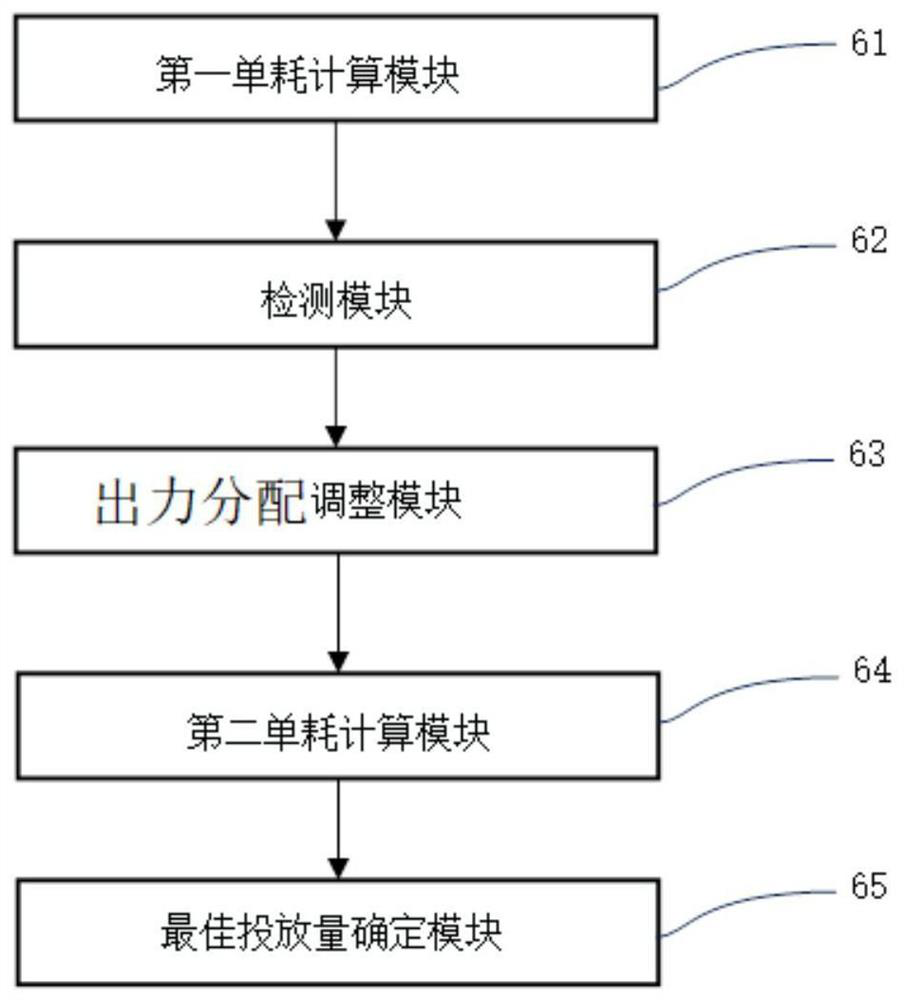

[0041] Such as figure 1 As shown, the setting method for the collaborative optimization of the desulfurization system and dust removal system of the thermal power unit in this embodiment, the method calculates the first unit consumption of the boiler within a fixed time based on the output distribution of the desulfurization system and the dust removal system of the thermal power unit; secondly, detects the The emission of sulfur dioxide and dust particles in the flue gas within a fixed period of time; based on the emission of sulfur dioxide and dust particles in the flue gas, the output distribution of the desulfurization system and dust removal system of the thermal power unit is regularly adjusted; and then calculated under the adjusted output distribution , the second unit consumption of the boiler within the fixed time; finally, based on the first unit consumption and the second unit consumption, it is determined that the output allocation corresponding to the minimum unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com