Microgel for stabilizing and controlling the release of biological enzyme in laundry liquid and laundry liquid comprising the same

A technology of laundry detergent and microgel, applied in the field of laundry detergent, can solve the problems of great influence on stability, complicated preparation method, no universality, etc., and achieves wide application range, simple operation process, and flexible particle size adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Using the compound method of agar, xanthan gum and gellan gum, dissolve 0.7g of agar, 0.2g of xanthan gum, and 0.2g of gellan gum in 80mL of water at 80-90℃ to form a matrix solution, and then cool down to 40-42 ℃ standby;

[0085] Add 20g of protease solution (enzyme activity value of 190,000 U / g) into the matrix, stir well to make the protease evenly dispersed;

[0086] After mixing, drop the matrix into 20L polydimethylsiloxane using a pill-dropping machine (10CP:50CP is 1:1), use deionized water to clean the microgel, remove the oil on the surface, and obtain a microgel containing protease. gel;

[0087] Use 1mm, 1.5mm, and 2mm drip tips respectively to make gel, and the temperature of the cooling medium is 9-12°C.

[0088] After testing by UV spectrophotometer, the encapsulation rate of protease was calculated to be 92%.

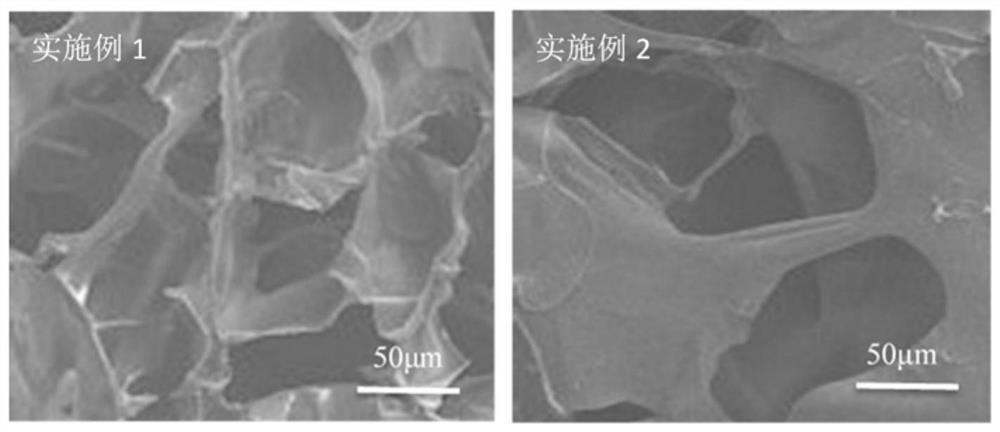

[0089] Take a microgel and place it in an oven. After drying, slice it to observe the network structure of the gel. figure 1 shown, through ...

Embodiment 2

[0093] Using the compound method of agar, sodium alginate and hydroxyethyl cellulose, dissolve 0.5g of agar, 0.2g of sodium alginate, and 0.1g of hydroxyethyl cellulose in 80 mL of water at 80 to 90°C to form a matrix solution and cool down. To 40 ~ 42 ℃ standby;

[0094] Add 20g of protease solution (enzyme activity value of 190,000 U / g) into the matrix, stir well to make the protease evenly dispersed;

[0095] After mixing, the matrix was dropped into 5L calcium chloride aqueous solution (concentration-0.5wt%) using a pill-dropping machine, and the microgel encapsulated with protease was obtained after filtration.

[0096] 1mm, 1.5mm, and 2mm drip tips were used to prepare gels, and the concentration of the calcium chloride aqueous solution was 0.5%.

[0097] After testing by UV spectrophotometer, the encapsulation rate of protease was calculated to be 90%.

[0098] Take a microgel and place it in an oven. After drying, slice it to observe the network structure of the gel....

Embodiment 3

[0103] Using the compound method of agar, xanthan gum and hydroxyethyl cellulose, dissolve 0.7g of agar, 0.2g of xanthan gum, and 0.1g of hydroxyethyl cellulose in 80 mL of water at 80 to 90 °C to form a matrix solution and cool down. To 40 ~ 42 ℃ standby;

[0104] Add 20 g of protease solution (enzyme activity of 100,000 U / g) into the matrix solution and stir well to make the protease evenly dispersed;

[0105] After mixing, the matrix was dropped into 1L mixed polydimethylsiloxane (10CP:50CP was 1:5) using a pill-dropping machine, and the microgel was washed with deionized water to remove the oil on the surface to obtain a microgel containing protease. glue.

[0106] Gels were prepared by using 1mm, 1.5mm and 2mm drippers respectively, polydimethylsiloxane was selected as the cooling medium, and the temperature of the cooling medium was selected as 15-20°C.

[0107] After testing by UV spectrophotometer, the encapsulation rate of protease was calculated to be 96%.

[0108...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com