Hydrogen fuel cell stack structure

A fuel cell stack and electric stack technology, which is applied to fuel cells, circuits, electrical components, etc., can solve problems such as low efficiency, fatigue failure of bolts, and low strength of bolted joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

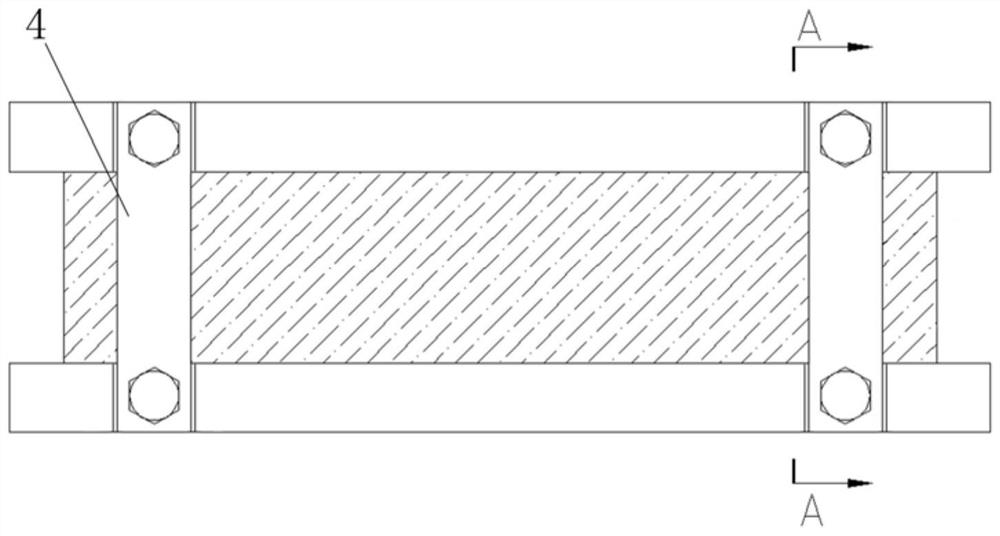

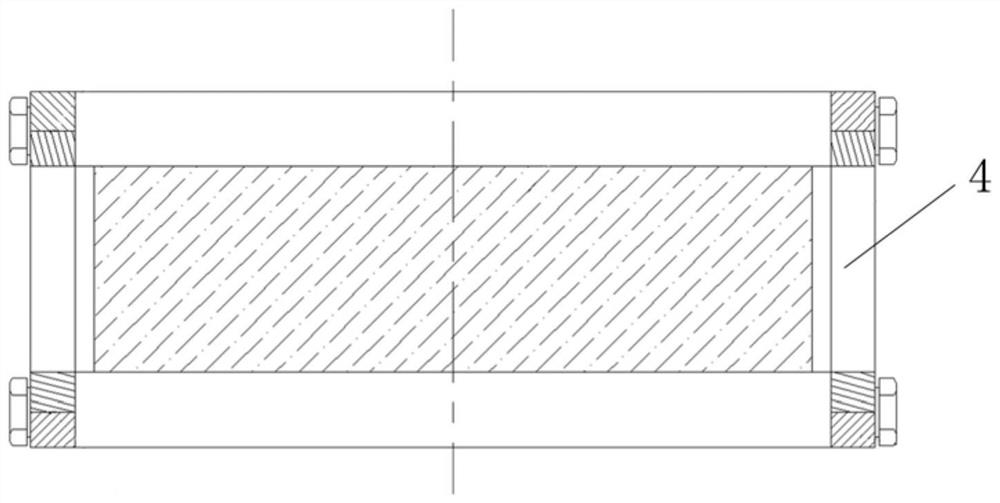

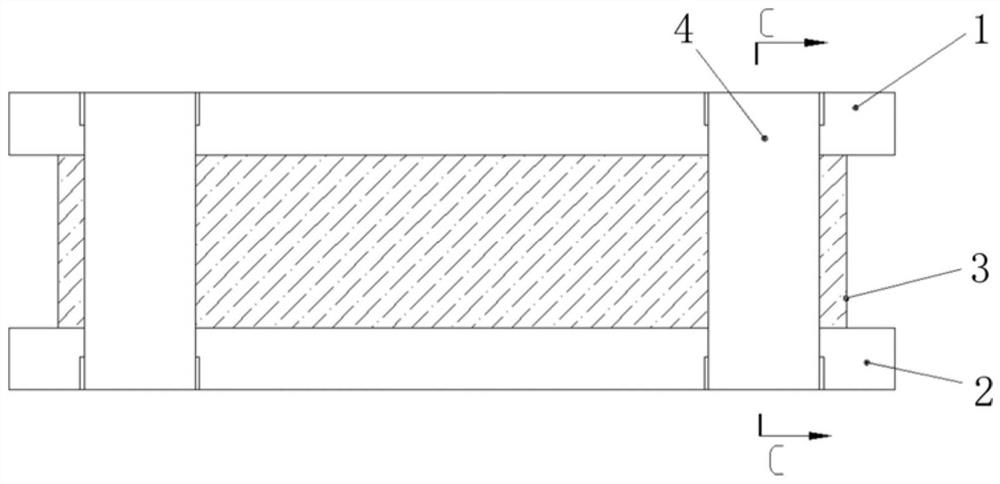

[0030] Such as Figure 3-5 As shown, this embodiment provides a hydrogen fuel cell stack structure, including an upper end plate 1 of the stack, a lower end plate 2 of the stack, a core 3 of the stack and a plurality of tie rods 4 . The electric stack core 3 is a conventional electric stack core 3 composed of bipolar plates and membrane electrodes. The stack core 3 is fixed between the upper end plate 1 of the stack and the lower end plate 2 of the stack, and the sides of the end plates are directly fixed by tie rods 4 . The number of pull rods 4 is at least four to ensure the strength of the installation. In this embodiment, four are preferred, and they are symmetrically arranged on both sides of the upper end plate 1 of the electric stack and the lower end plate 2 of the electric stack. The concrete structure of end plate and tie rod 4 is as follows:

[0031] Barbs 41 are provided at the top and bottom of each pull rod 4 . The barb 41 is a trapezoidal block, and the shor...

Embodiment 2

[0034] The overall structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: Figure 6 As shown, the two ends of the tie rod 4 are "T"-shaped ends 43, the upper end plate 1 of the electric stack and the lower end plate 2 of the electric stack are provided with "T"-shaped fitting grooves, and the two ends of the tie rod 4 are respectively embedded and fitted. in the slot. The "T"-shaped fitting connection is conducive to improving the strength of installation and fixing, and has the functions of positioning and foolproofing.

Embodiment 3

[0036] The overall structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: Figure 7 As shown, the barb 41 is provided with a positioning rib 42 , and the positioning rib 42 is vertically arranged at the center of the barb 41 . A longitudinal gap is provided in the slot 5 for embedding the positioning rib 42 . The positioning rib 42 can play the role of positioning support and improve the positioning progress of the end plate and the tie rod 4. It is only necessary to fix and fit the positioning rib 42, so that both sides of the tie rod 4 can have a certain redundant gap and reduce the difficulty of installation. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com