Cassava vermicelli production equipment for food production

A production equipment and cassava technology, which are applied in the field of cassava vermicelli production equipment for food production, can solve the problems of inability to automatically scrape strips, inability to realize automatic collection of cassava vermicelli, and multiple cutting of cassava.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

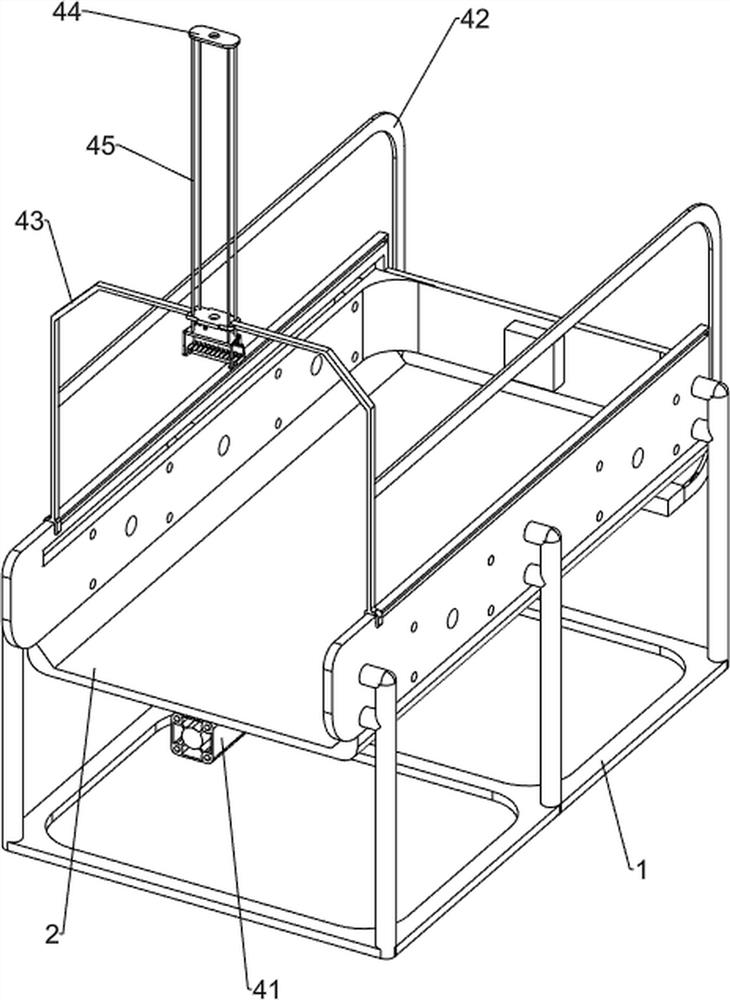

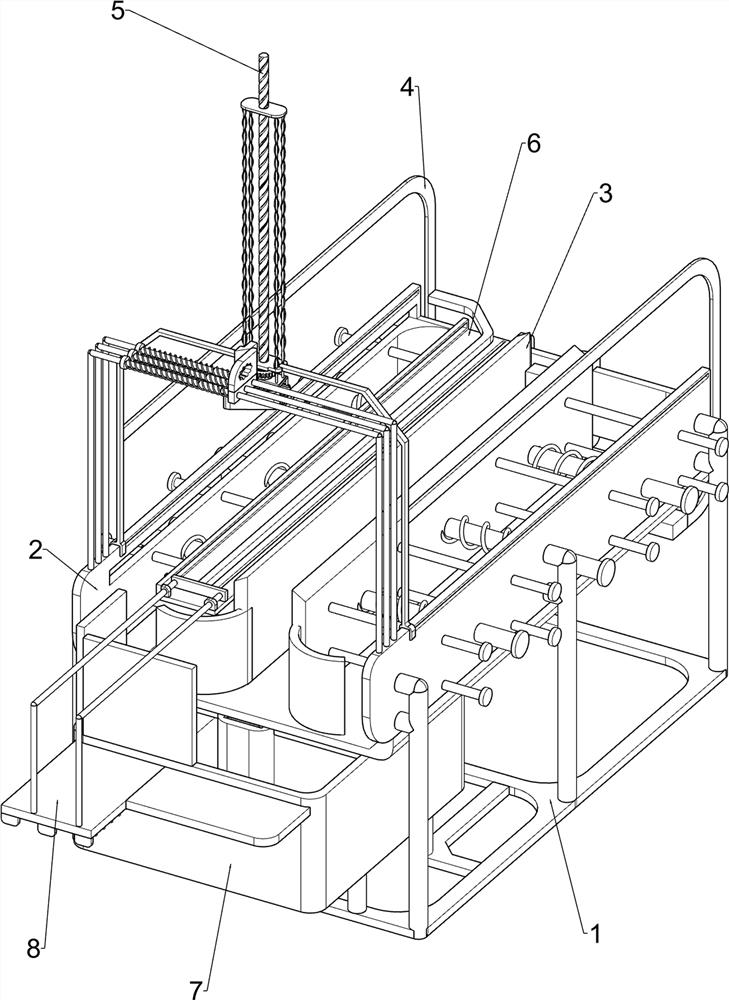

[0070] A kind of cassava vermicelli production equipment for food production, such as Figure 1-12 As shown, it includes a fixed frame 1, a workbench 2, a clamping mechanism 3 and a scraper mechanism 4. The fixed frame 1 is provided with a workbench 2, and the workbench 2 is provided with a clamping mechanism 3. Scraping mechanism4.

[0071] When people want to scrape cassava pieces into vermicelli, they can use this cassava vermicelli production equipment for food production. At first, the user pushes the clamping mechanism 3 outwards, then places the cassava on the workbench 2, loosens it Open the clamping mechanism 3, the clamping mechanism 3 moves inwardly, the clamping mechanism 3 contacts with the cassava, thereby clamps the cassava block, the user starts the scraping mechanism 4 again, and the scraping mechanism 4 cuts the cassava block, thereby Form cassava vermicelli, after the cassava vermicelli is all produced, close the scraper mechanism 4, and the user collects t...

Embodiment 2

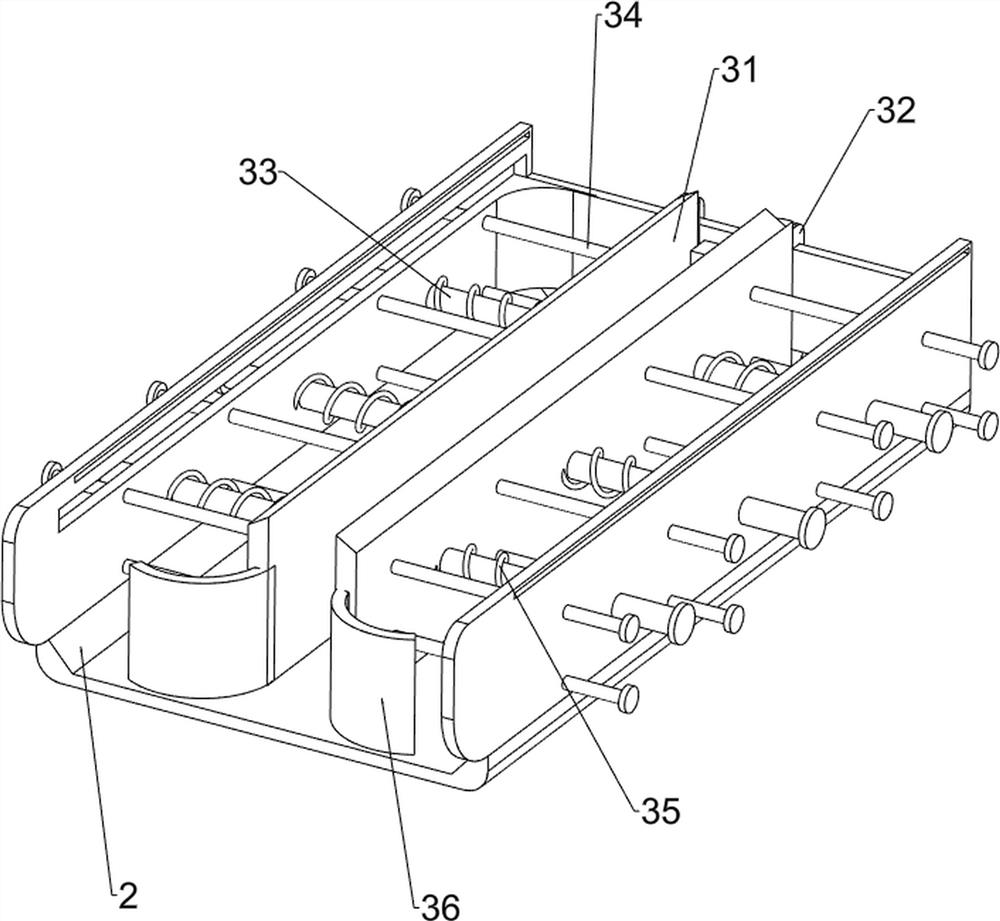

[0073] On the basis of Example 1, such as Figure 2-Figure 4 As shown, the clamping mechanism 3 includes a clamping plate 31, a short limit frame 32, a main stabilizing bar 33, an auxiliary stabilizing bar 34, a clamping spring 35 and an arc plate 36, and the left and right sides of the workbench 2 are all slidingly designed. There are eight auxiliary stabilizing rods 34, and clamping plates 31 are connected between the eight auxiliary stabilizing rods 34 on the same side, and the rear walls of the two clamping plates 31 are provided with short limit frames 32, which are connected with the working table 2 Sliding connection, the left and right sides of the workbench 2 are slidingly provided with three main stabilizing bars 33, the three main stabilizing bars 33 on the same side are connected with the clamping plate 31, and the six main stabilizing bars 33 are all wound with clamping springs 35 , two ends of the clamping spring 35 are connected with the workbench 2 and the clam...

Embodiment 3

[0078] On the basis of Example 2, such as Figure 5-Figure 12 Shown, also include pressing mechanism 5, and pressing mechanism 5 includes dense connecting rod 51, slide short tooth bar 52, contraction spring 53, flashboard 54, first back-moving spring 55, threaded rod 56, full gear 57 and One-way limit ring 58, three dense connecting rods 51 are arranged on the top of the front side of the workbench 2, and the upper middle of the three dense connecting rods 51 is slidably connected with a sliding short rack 52, and the upper left side of the three dense connecting rods 51 is all wound with shrinkage Spring 53, the two ends of contraction spring 53 are respectively connected with intensive connecting rod 51 and sliding short rack 52, and the top of positioning thin rod 43 is provided with flashboard 54, and flashing plate 54 cooperates with sliding short rack 52, and four connecting thin rods 45 The first return spring 55 is wound on the top, and the two ends of the first retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com