Waterproof dry-mixed mortar for plastering and preparation method of mortar

A technology of dry powder mortar and water resistance, which is applied in the field of dry powder mortar and can solve problems such as hollowing, falling off, and poor water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

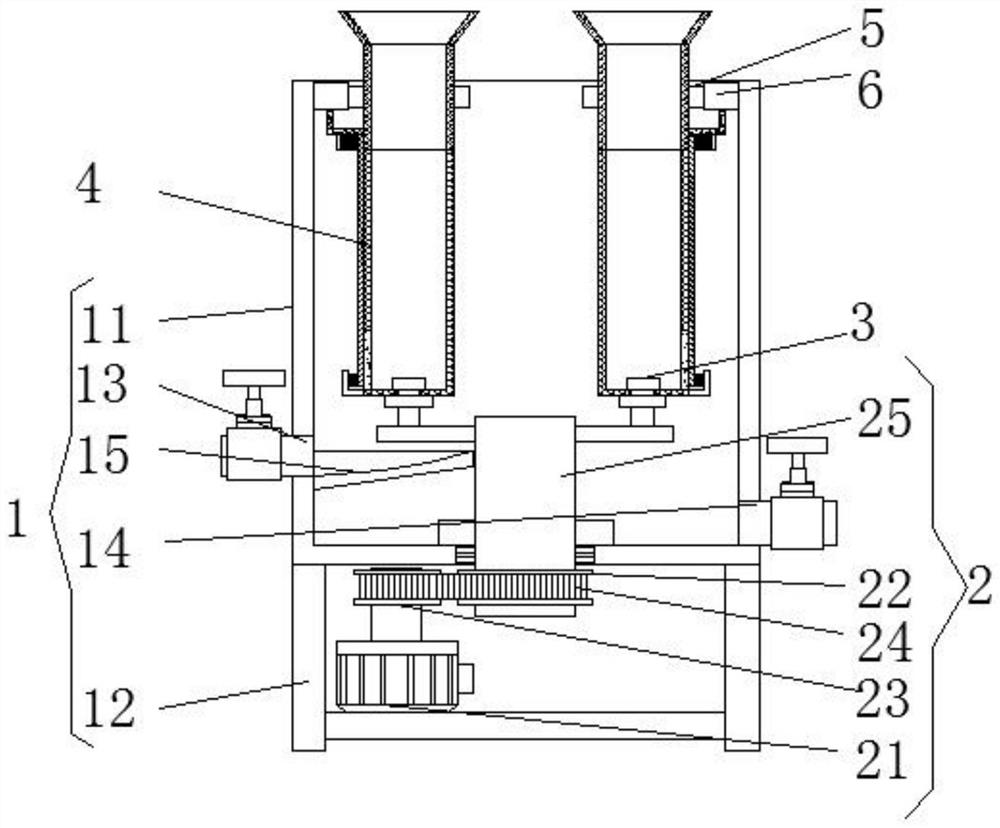

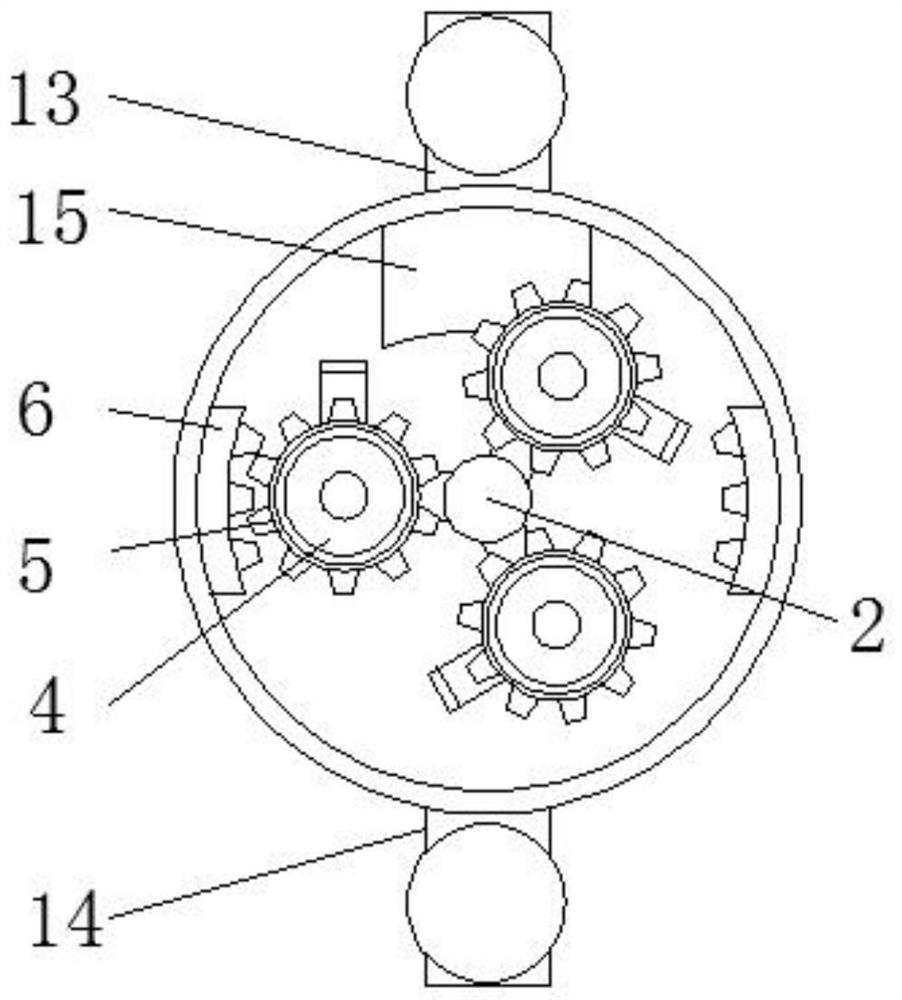

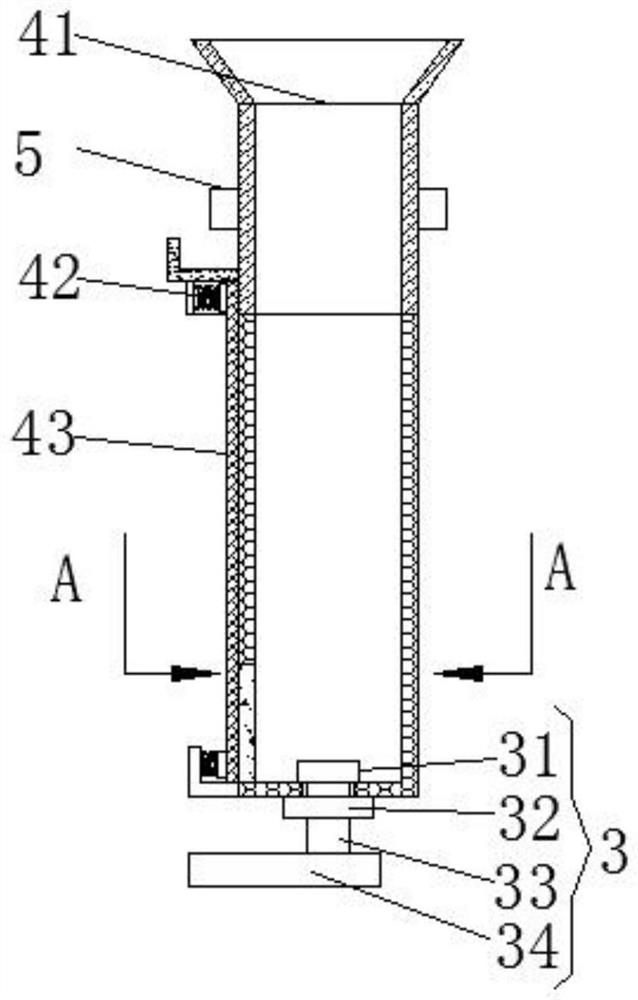

Image

Examples

Embodiment 1

[0041] Waterproof plastering dry powder mortar, made of the following raw materials in parts by mass:

[0042] 18.6% cement, 81% sand, 0.3% thickened powder and 0.1% waterproof additive.

[0043] The preparation method of waterproof plastering dry powder mortar, described preparation method comprises the following steps:

[0044] S1. Preparation of sand

[0045] Put the collected river sand into the cleaning machine for cleaning, and the cleaned river sand is conveyed to the three-pass drum dryer through the belt for sealing and drying, and the dried river sand is conveyed to the screening machine through the belt Screening is carried out inside, and the sand with different particle sizes screened out is sent to different dry sand drums for storage;

[0046] S2. Storage of various raw materials

[0047] Send the required cement to the cement cylinder for storage, the thickened powder to the thickened powder cylinder for storage, and the waterproof additive to the additive c...

Embodiment 2

[0055] Waterproof plastering dry powder mortar, made of the following raw materials in parts by mass:

[0056] 19.8% cement, 79.73% sand, 0.35% thickening powder and 0.12% waterproof additive.

[0057] The preparation method of waterproof plastering dry powder mortar, described preparation method comprises the following steps:

[0058] S1. Preparation of sand

[0059] Put the collected river sand into the cleaning machine for cleaning, and the cleaned river sand is conveyed to the three-pass drum dryer through the belt for sealing and drying, and the dried river sand is conveyed to the screening machine through the belt Screening is carried out inside, and the sand with different particle sizes screened out is sent to different dry sand drums for storage;

[0060] S2. Storage of various raw materials

[0061] Send the required cement to the cement cylinder for storage, the thickened powder to the thickened powder cylinder for storage, and the waterproof additive to the addi...

Embodiment 3

[0069] Waterproof plastering dry powder mortar, made of the following raw materials in parts by mass:

[0070] 21% cement, 78.55% sand, 0.35% thickened powder and 0.1% waterproof additive.

[0071] The preparation method of waterproof plastering dry powder mortar, described preparation method comprises the following steps:

[0072] S1. Preparation of sand

[0073] Put the collected river sand into the cleaning machine for cleaning, and the cleaned river sand is conveyed to the three-pass drum dryer through the belt for sealing and drying, and the dried river sand is conveyed to the screening machine through the belt Screening is carried out inside, and the sand with different particle sizes screened out is sent to different dry sand drums for storage;

[0074] S2. Storage of various raw materials

[0075] Send the required cement to the cement cylinder for storage, the thickened powder to the thickened powder cylinder for storage, and the waterproof additive to the additive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com