High-efficiency RH decarburization method

A high-efficiency, decarburization technology, applied in the field of steelmaking, can solve the problem of low RH decarburization efficiency, and achieve the effect of improving decarburization efficiency, reducing costs, and increasing decarburization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

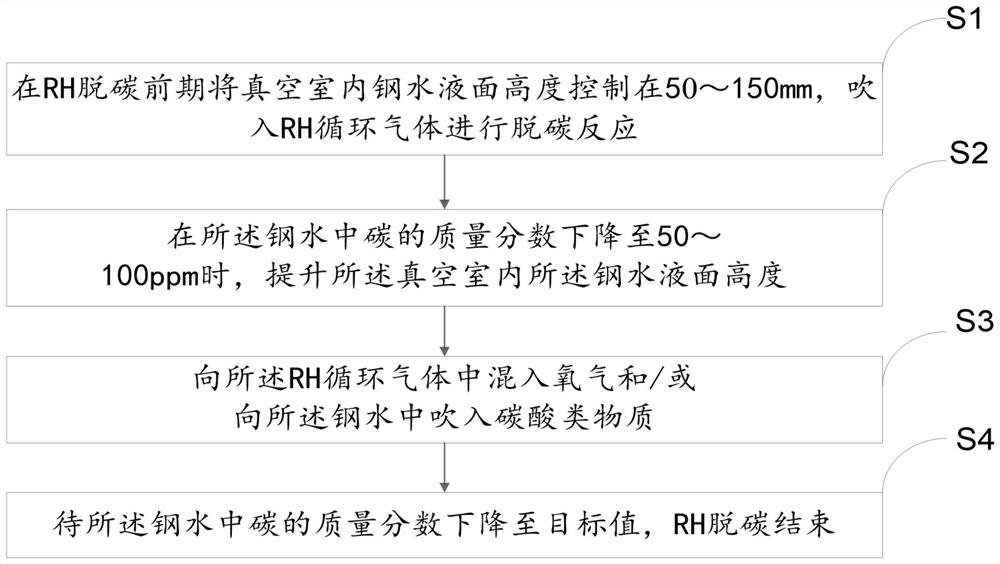

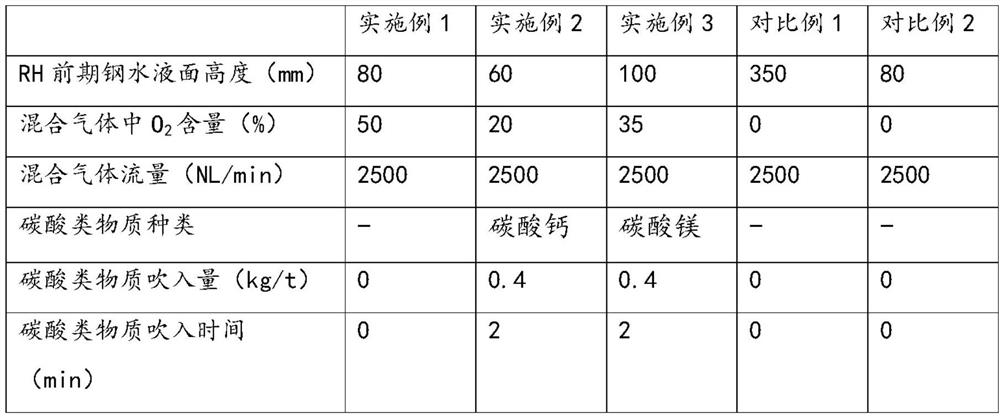

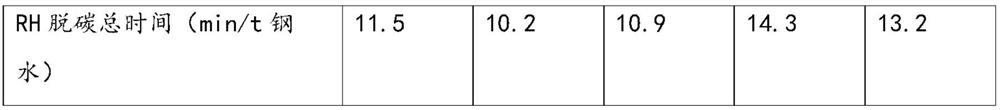

[0068] A high-efficiency RH decarburization method in this embodiment comprises the following steps:

[0069] (1) In the early stage of RH decarburization, when the gas pressure in the vacuum chamber is measured to be ≤3.9KPa, the height of the liquid steel level in the vacuum chamber is controlled at 50-150mm, and argon gas with a flow rate of 2000NL / min is blown in to carry out the decarburization reaction , and the duration is 9 minutes.

[0070] (2) When the mass fraction of carbon in the molten steel drops to 100ppm, raise the molten steel level in the vacuum chamber to 400mm, and mix oxygen into the argon gas, and continue the reaction for 5 minutes;

[0071] In the mixed gas composed of argon and oxygen, the volume fraction of the oxygen is 5-50%, and the flow rate of the mixed gas is 2400-3200 NL / min.

[0072] (3) and / or: carbonic acid substances are blown into the molten steel through the circulation holes of the dipping tube, and the carbonic acid substances include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com