Efficient sock end sewing machine and using method thereof

A technology for sewing head machines and socks, which is applied in sewing machine components, sewing equipment, textiles and papermaking, etc., and can solve the problems of easily hot sewing needles, shedding of fine fibers, and dust pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

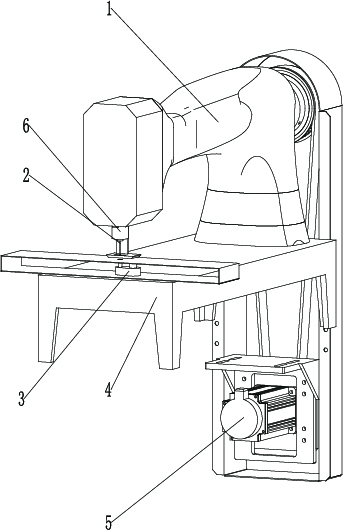

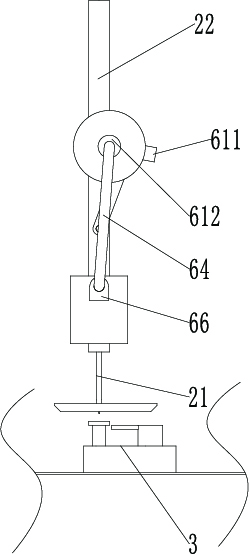

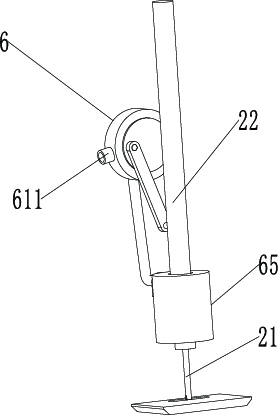

[0024] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1-Figure 8 ,

[0025] A high-efficiency sock sewing machine, comprising a sewing machine main body 1, a motor 5 and a base 4, the sewing machine main body 1 and the motor 5 are arranged on the base 4, and the motor 5 is connected to the sewing machine main body 1 through a belt, and the sewing machine main body 1 The needle point part 2 and the dust suction part 6 are arranged on it, the needle point part 2 includes a needle point driving rod 22 and a sewing needle 21, the needle point driving rod 22 is provided with a first rotating rod 221, and the sewing needle 21 is arranged on the needle point The bottom of the driving rod 22 and the bottom of the sewing needle 21 are provided with a threading hole 211 , and the sewing thread passes through the threading hole 211 .

[0026] The dust suction part 6 includes a fan cover 61, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com