Early-dismantling formwork system and construction method thereof

A technology for early dismantling of formwork and systems, which is applied to the preparation of formwork/formwork/work frame, pillars, and building components on site, which can solve the problems of tediousness, difficulty, and floor formwork that is easy to hit the staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the examples.

[0039] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

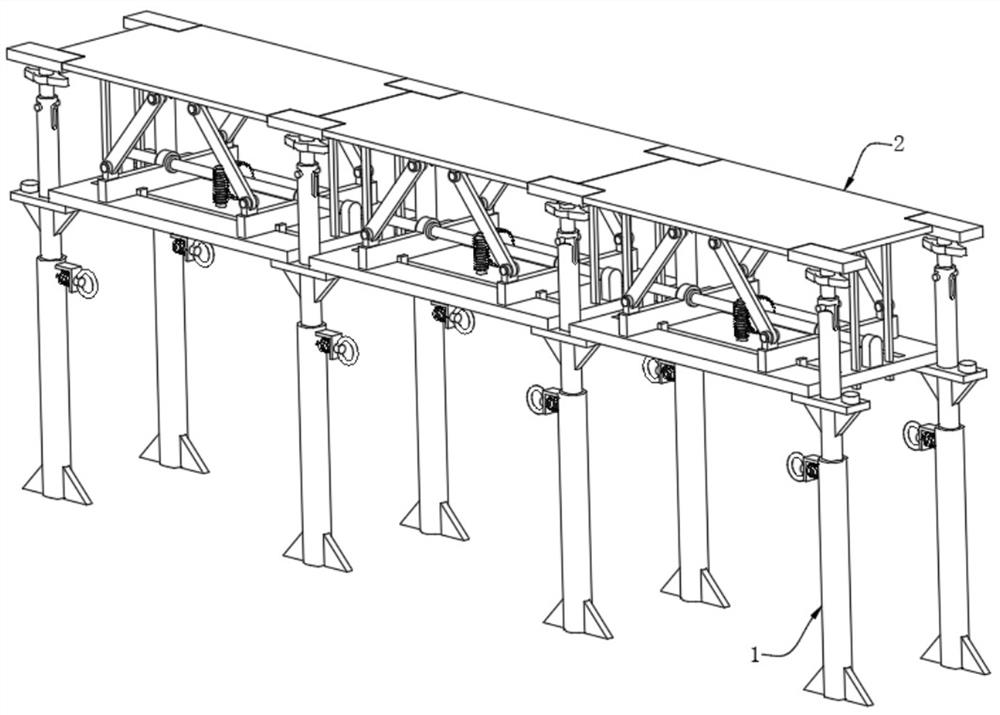

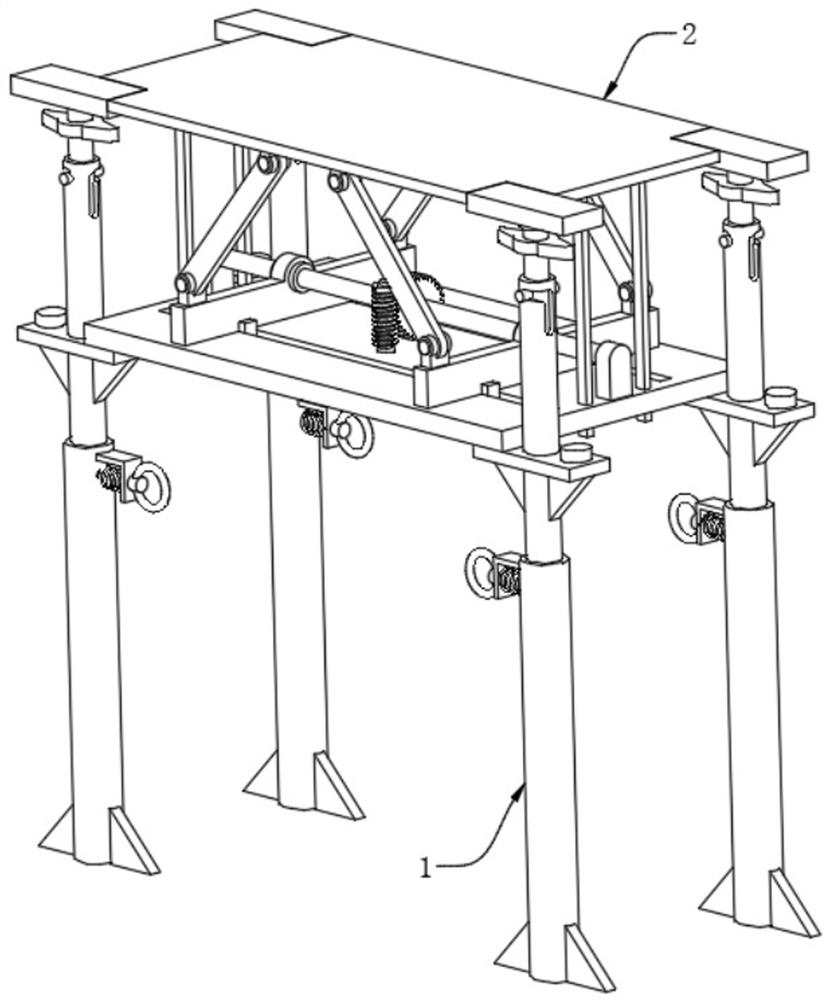

[0040] see Figure 1-7 , the present invention provides an early demolition formwork system, including a support assembly 1 and a pallet assembly 2, the number of support assemblies 1 is at least four, and a pallet assembly 2 is built between the four support assemblies 1;

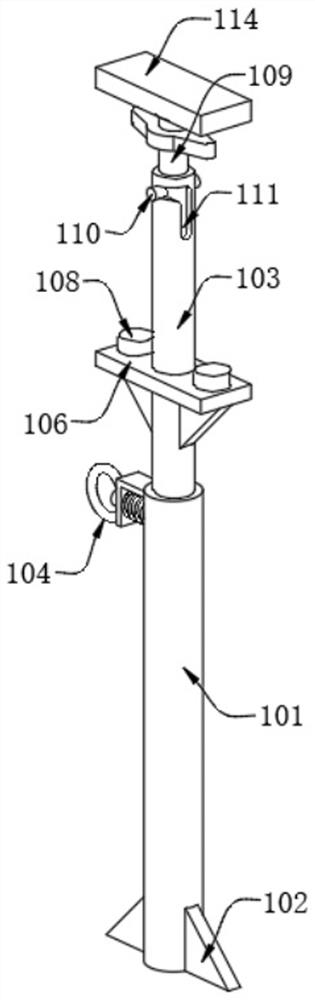

[0041] The support assembly 1 includes a fixed column 101, and a lifting column 103 is movably connected to the fixed column 101. The outer wall of the fixed column 101 is fixed with a li...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap