Food package sealing detection equipment

A sealing detection and food packaging technology, which is applied in fluid tightness testing, measuring devices, testing of machine/structural components, etc. It can solve the problem of simultaneous detection of multiple connected packaging bags in strips, low detection efficiency, and loss of packaging bags The meaning of preservation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

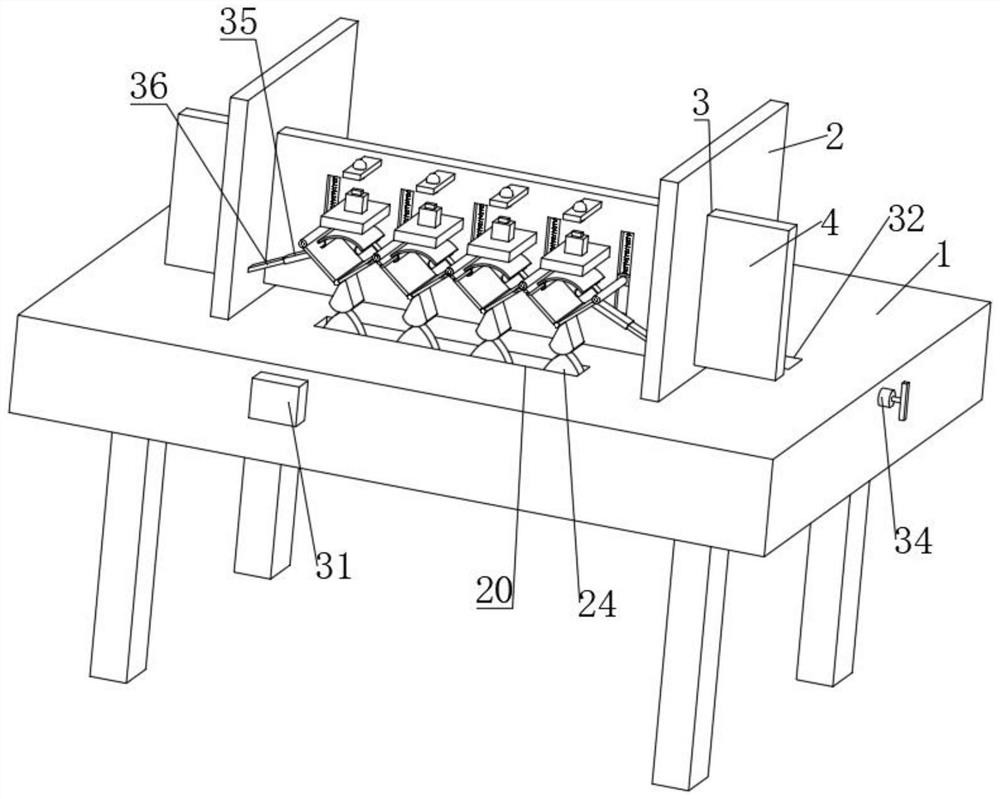

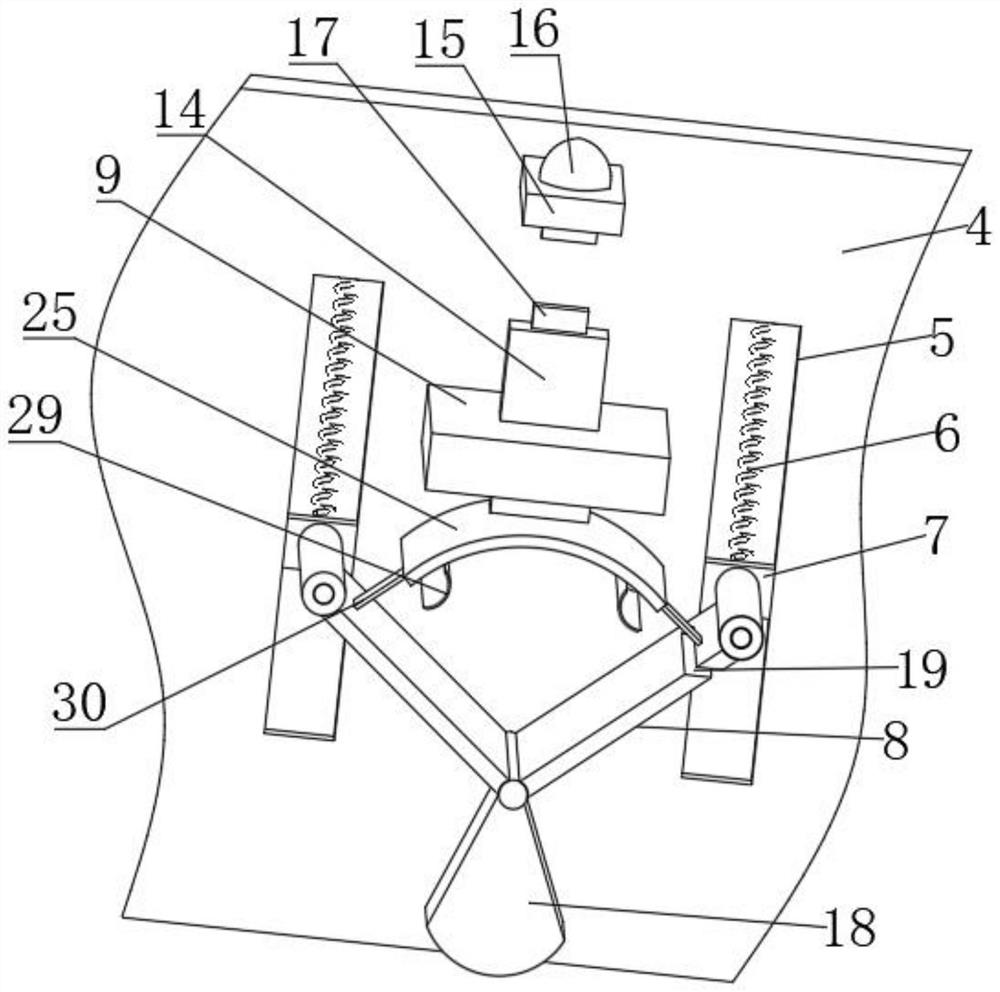

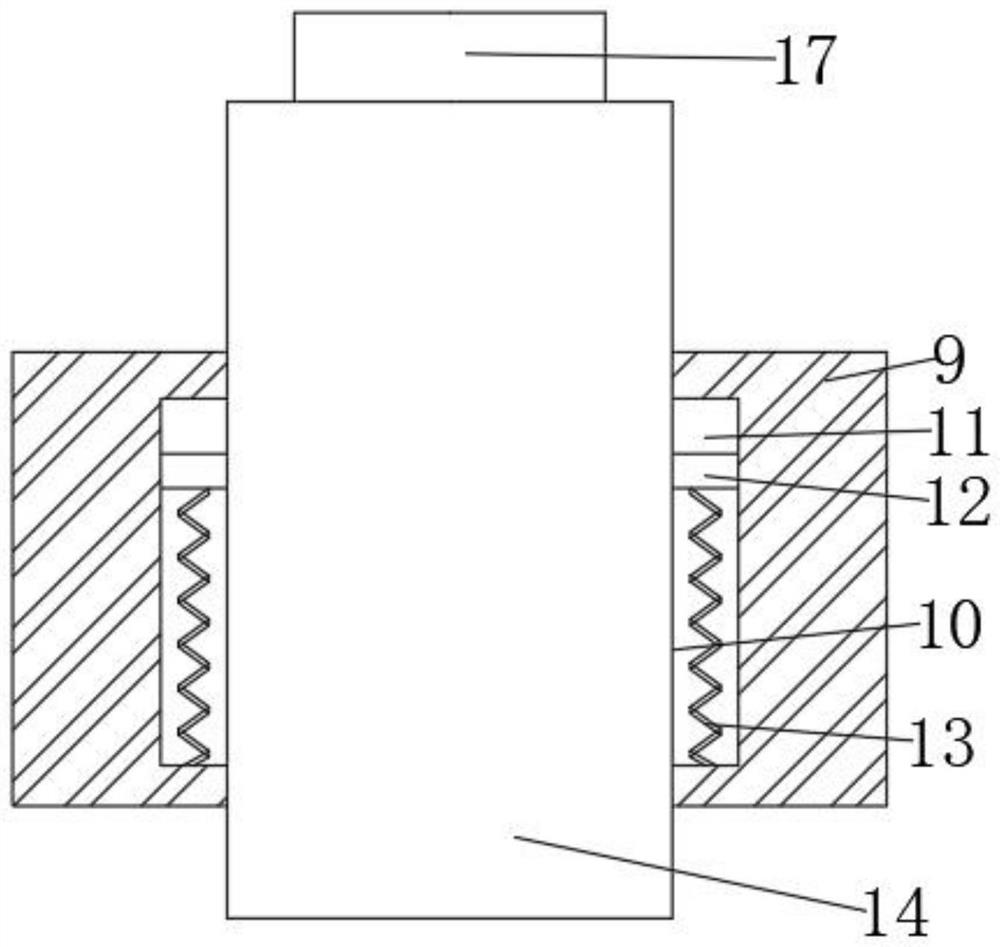

[0027] refer to Figure 1-5 , a kind of food packaging sealing testing equipment, comprising a workbench 1, two side plates 2 are fixed symmetrically on both sides of the top of the workbench 1 by bolts, and the same vertical plate 4 is fixed by bolts between the two side plates 2, the vertical plate 4 The front end is provided with a plurality of evenly distributed first chute 5, and the first chute 5 is slidably connected with the first slider 7, and the first slider 7 and the inner wall of the first chute 5 are fixed by bolts. The first spring 6, the front end of the first slider 7 is rotatably connected with the lower pressure plate 8 through the bearing, the two adjacent lower pressure plates 8 are rotatably connected through the bearing, and the bottom of the adjacent two lower pressure plates 8 is movably connected with the same impact block 18 , The front end of the lower pressing plate 8 is provided with a third opening 19, the workbench 1 is provided with a driving m...

Embodiment 2

[0036] refer to Figure 1-6 , a food packaging seal detection equipment, the top of the workbench 1 is provided with a third chute 32, the third chute 32 is slidingly connected with two third sliders 33, and the third chute 32 is connected with a screw through a bearing rotation 34. One side of the screw rod 34 extends to the outside of the workbench 1 and is fixed with a handle by bolts. There is a set of reverse threads on the screw rod 34. The screw rod 34 and the two third sliders 33 are connected through the threads, and the top of the third slider 33 passes through The side plate 2 is fixed by bolts, the first opening 3 is opened through the side plate 2, the vertical plate 4 is set in the first opening 3, and the outer surfaces of the two lower pressure plates 8 located on the side are connected with sleeves through bearing rotation. 35. An inner rod 36 is plugged into the sleeve 35, and the same fourth spring is fixed between the inner rod 36 and the sleeve 35 by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com