Combustion chamber

A combustor, gas turbine technology, which is applied in the fields of hot gas side, cold gas side and hot gas side and method, can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

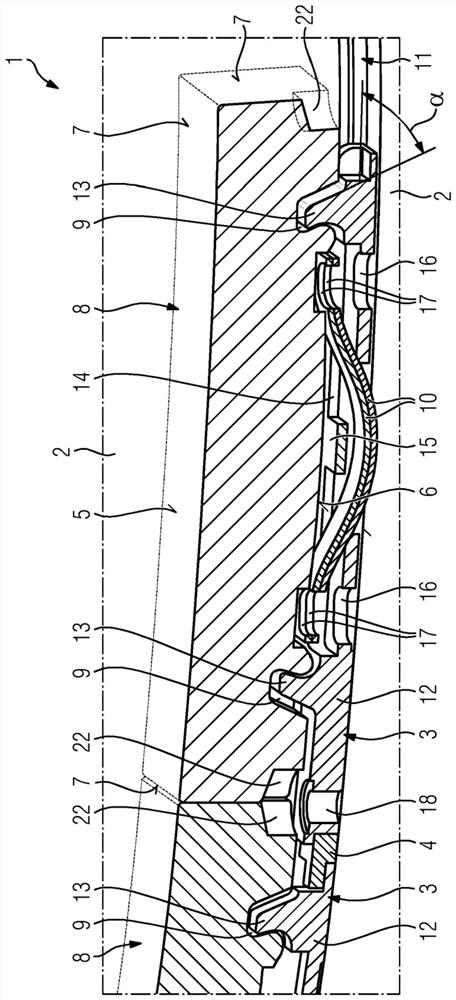

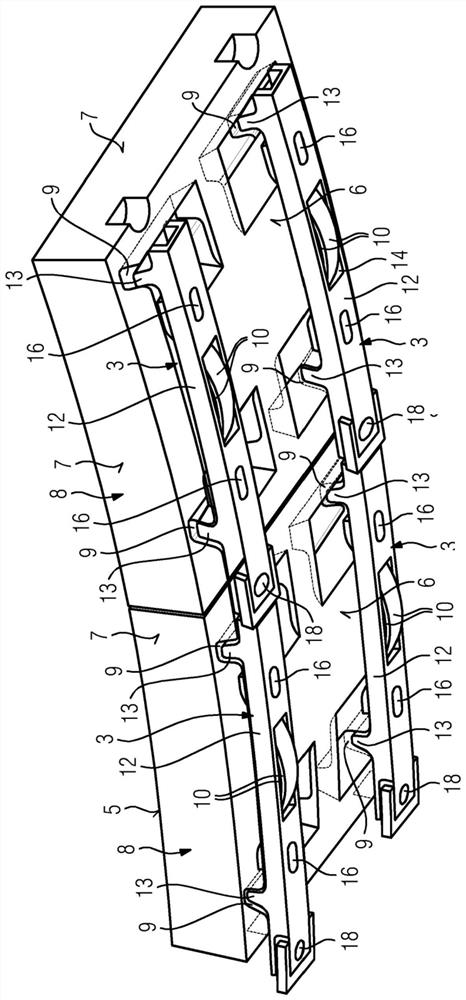

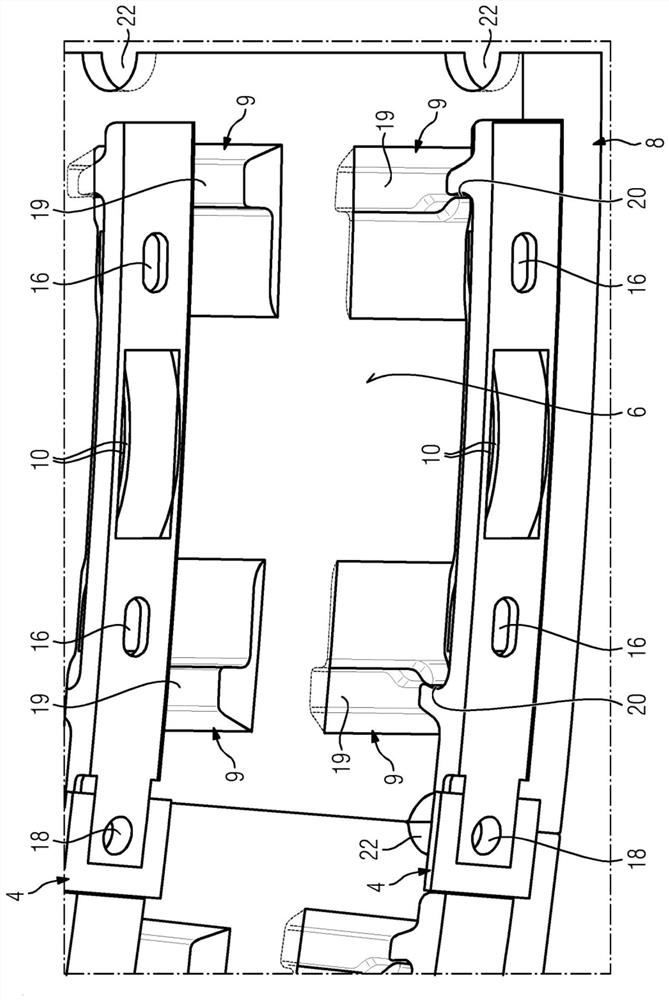

[0032] Figure 1 to Figure 6A combustion chamber 1 according to an embodiment of the invention is shown, which in the present case is a combustion chamber of a gas turbine. The combustion chamber 1 comprises: a load-bearing structure 2; a plurality of holding elements 3 fastened on the load-bearing structure 2; a plurality of connecting elements 4 interconnecting the holding elements 3 arranged adjacently in the circumferential direction U; a plurality of Heat shield elements 8 which together form a heat shield, each having a hot gas side 5 , a cold gas side 6 and an end side 7 connecting the hot gas side 5 and the cold gas side 6 to one another, wherein the holding element 3 Form-fittingly engages in a recess 9 provided on the heat shielding element 8; and a spring element 10 extending between the carrier structure 2 and the heat shielding element 8, held on the holding element 3, the spring Elements are currently available in the form of wave-bent leaf springs.

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com