Egg sorting equipment used before vaccine seeding

An egg and vaccine technology, applied in climate change adaptation, conveyors, poultry industry, etc., can solve problems such as reducing the accuracy of egg sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

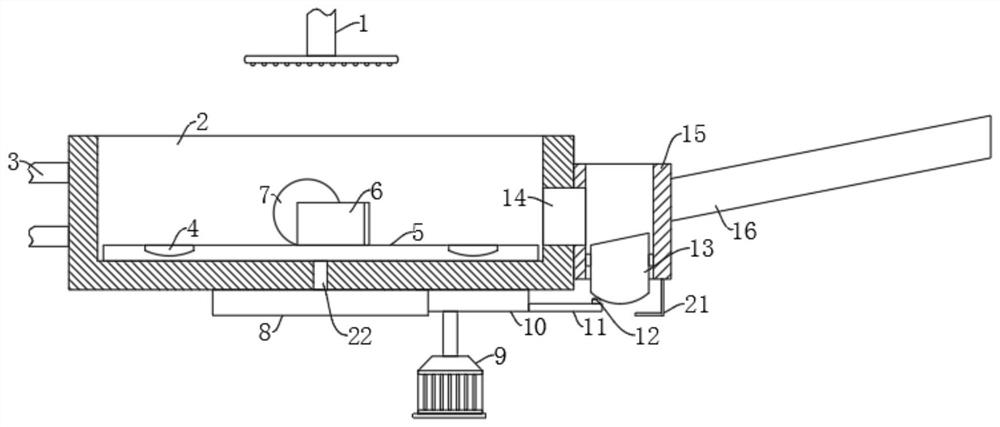

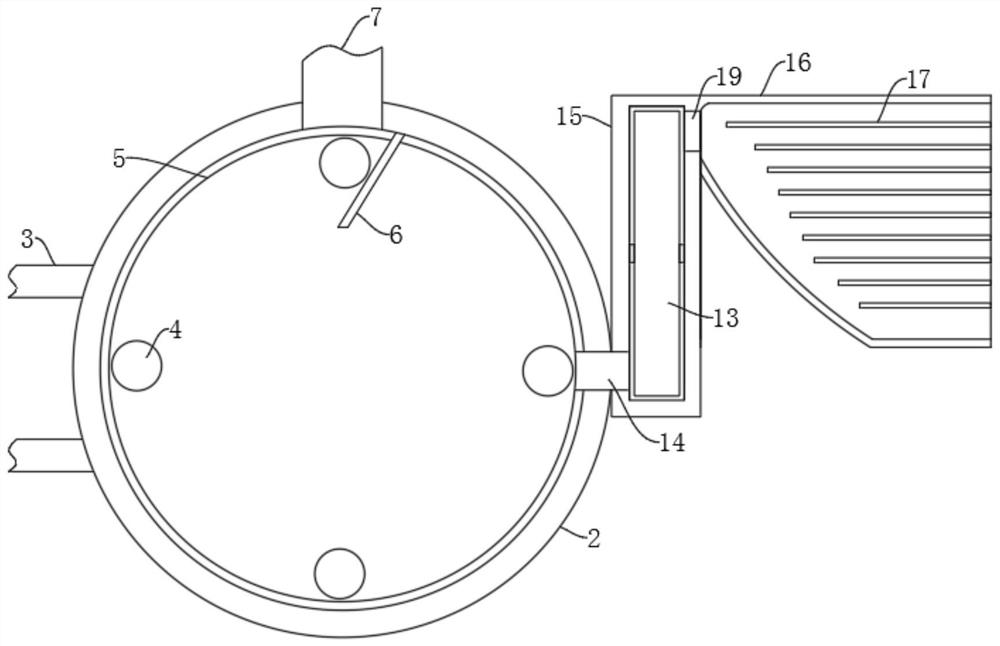

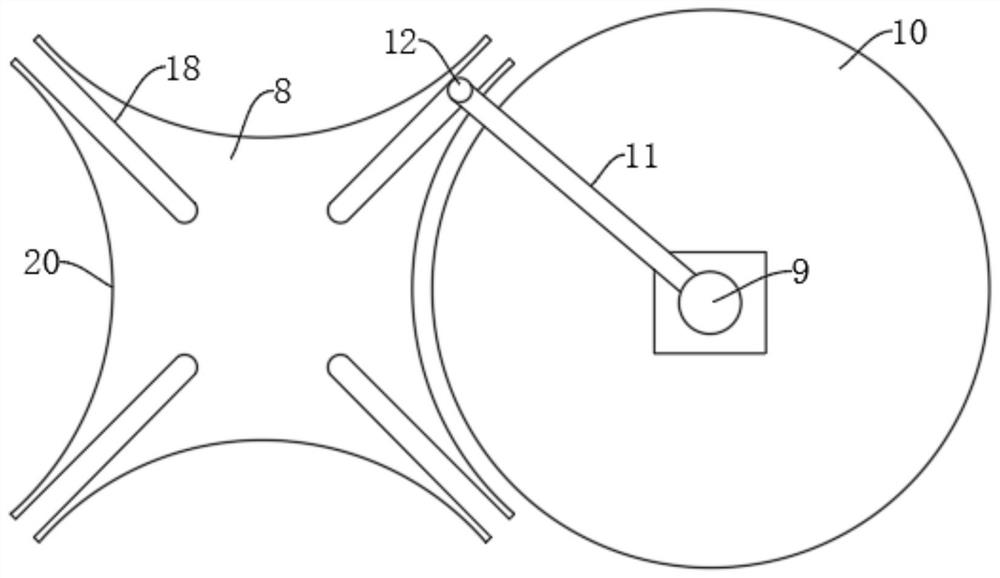

[0030] refer to Figure 1-3 and Figure 6 , a kind of egg sorting equipment before the vaccine is planted, comprises illuminating light 1, connecting frame 3, stepping motor 9, sorting box 2 and feeding structure, and the horizontal cross section of sorting box 2 is arranged circularly, and stepping motor 9. Connect the wire to the power supply device, and install an external control switch on the wire, and fix the sorting box 2 through the connecting frame 3 installed outside the sorting box 2, and the connecting frame 3 serves as a gap between the sorting box 2 and the frame. The connecting piece can stably fix the position of the sorting box 2, the stepping motor 9 is fixedly installed on the motor frame, the feeding structure is located outside the sorting box 2, and the illuminating lamp 1 is fixedly installed on the sorting box 2 through the light frame On the extension line of the axis line; the light of the illuminating lamp 1 is irradiated on the egg inside the slot ...

Embodiment 2

[0041] refer to Figure 1-2 , Figure 4 as well as Figure 6 , the difference between the present embodiment and Embodiment 1 is that a blanking structure is installed on the square frame 15 away from the sorting box 2, and the blanking structure includes a support 16, a through hole 19, a dividing plate 17 and a buffer pad 23, and the buffering The pad 23 can reduce the impact force between the egg and the partition 17, and realize the effect of protecting the egg. The bracket 16 is obliquely installed on the square frame 15 on the side away from the egg inlet 14, and the connection between the square frame 15 and the bracket 16 is located There is a through hole 19 that runs through the square frame 15. The size and height of the through hole 19 are the same as that of the egg inlet 14. The bracket 16 is arranged in a funnel shape, and the size of the end of the bracket 16 close to the square frame 15 is smaller than that far away from the square frame 15. One end dimensio...

Embodiment 3

[0043] refer to Figure 5 The difference between this embodiment and Embodiment 1 is that the eggs are placed in the egg trough inside the egg basket on the market. The traditional detection method includes manual detection. The detection personnel irradiate the eggs one by one by holding a flashlight. Observe, and then put the eggs that meet the standards back into the egg trough, which is easy to cause the situation of falling out of hands. In addition, traditionally, the whole basket of eggs is placed in a bright place to take pictures, and the eggs are screened through pictures, but the inside of an egg basket The egg troughs are distributed in a rectangular array and need to be marked. At the same time, when the workload increases, it is impossible to accurately and quickly find the inside of a certain egg trough in a specific egg basket where the eggs that do not meet the standards are located.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com