Logistics supply chain management platform with automatic sorting function

A logistics supply chain and automatic sorting technology, applied in sorting, chemistry, etc., can solve the problems of low degree of automation, susceptibility to virus infection, transmission of infectious diseases, etc., and achieve the effect of facilitating disinfection and avoiding carrying viruses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

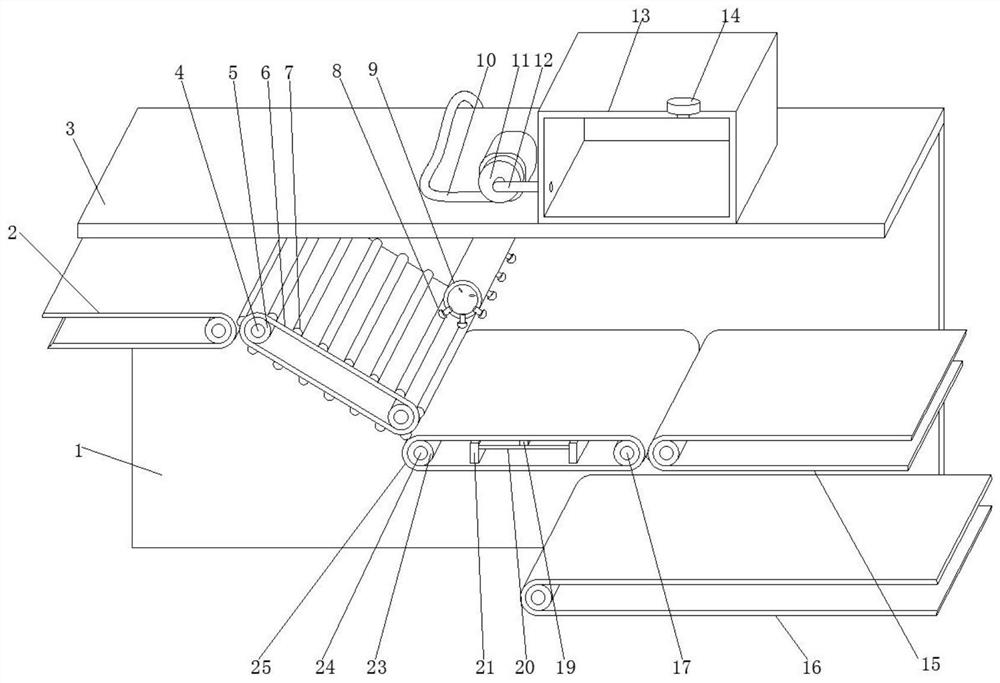

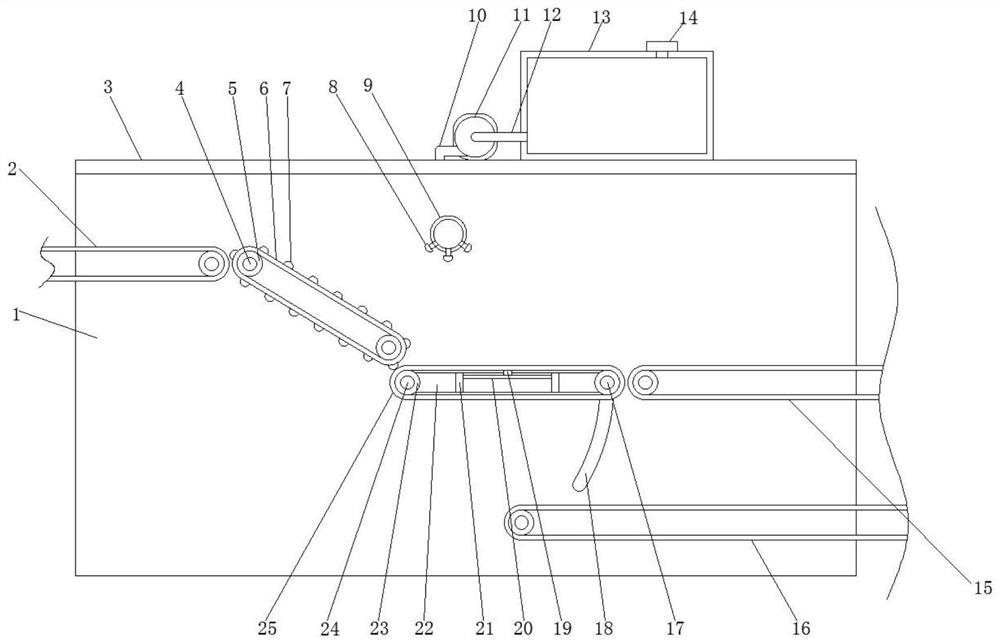

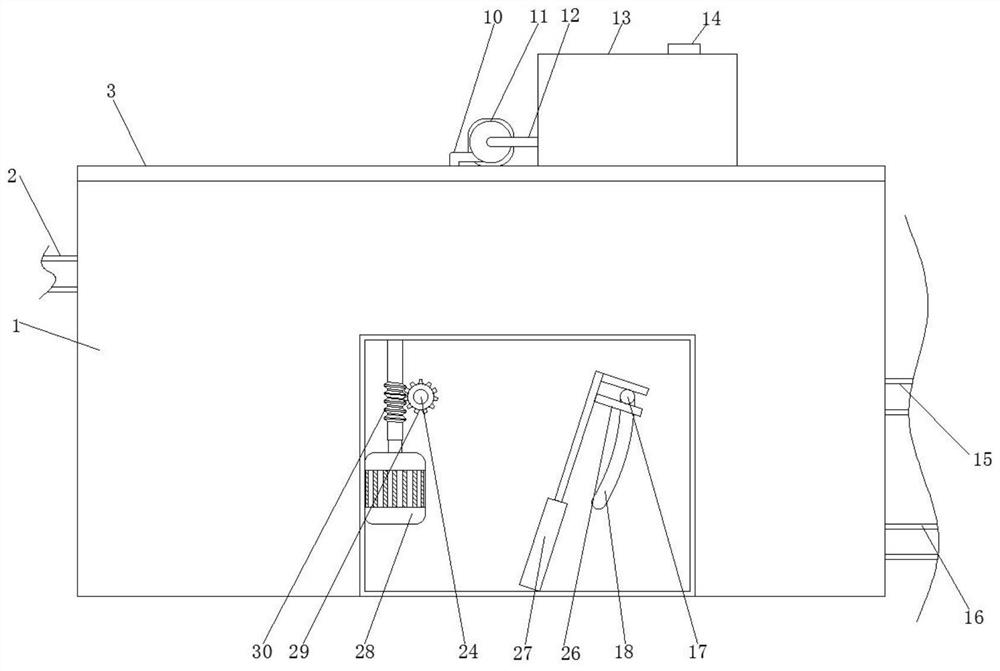

[0034] refer to Figure 1-3 , a logistics supply chain management platform with automatic sorting function, including two support plates 1, the top of the two support plates 1 is welded with a top plate 2, the top of the top plate 2 is provided with a liquid storage tank 13, and the two support plates 1 A liquid outlet pipe 9 is arranged between them, a connecting pipe 10 is arranged between the liquid outlet pipe 9 and the liquid storage tank 13, and two first rotating rods 4 are rotationally connected between the two support plates 1, and the two first rotating rods The outside of 4 is welded with a first roller 5, the outside of the first roller 5 is covered with a first conveyor belt 6, the first conveyor belt 6 is inclined, and a moving rod 17 and a second conveyor belt 24 are arranged between the two support plates 1, The outside of the moving rod 17 and the second conveyor belt 24 are welded with a second roller 23, the outside of the second roller 23 is sleeved with a ...

Embodiment 2

[0050] refer to Figure 4 , a logistics supply chain management platform with automatic sorting function. Compared with Embodiment 1, in this embodiment, in order to increase the stability of the device, the inside of the chute 18 is slidably connected with a slider 31, and the middle part of the slider 31 is opened There is a circular through hole, and the moving rod 17 is rotatably connected with the slider 31 at the circular through hole, and the moving rod 17 is facilitated to move inside the chute 18 through the slider 31, and at the same time, it is convenient for the moving rod 17 to rotate while moving , to improve the stability of device operation.

[0051] Working principle: when the material enters the interior of the device, it will move downward with the inclined first conveyor belt 6. During the movement, the liquid outlet pipe 9 will spray disinfectant on the surface of the material to disinfect the material, and then the material will be Falling on the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com