Apparatus for washing containers

A technology for washing containers and equipment, applied in cleaning methods and utensils, chemical instruments and methods, spraying devices with movable outlets, etc., can solve the problems of complex ATEX instructions, achieve the effects of small size, flexible management, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

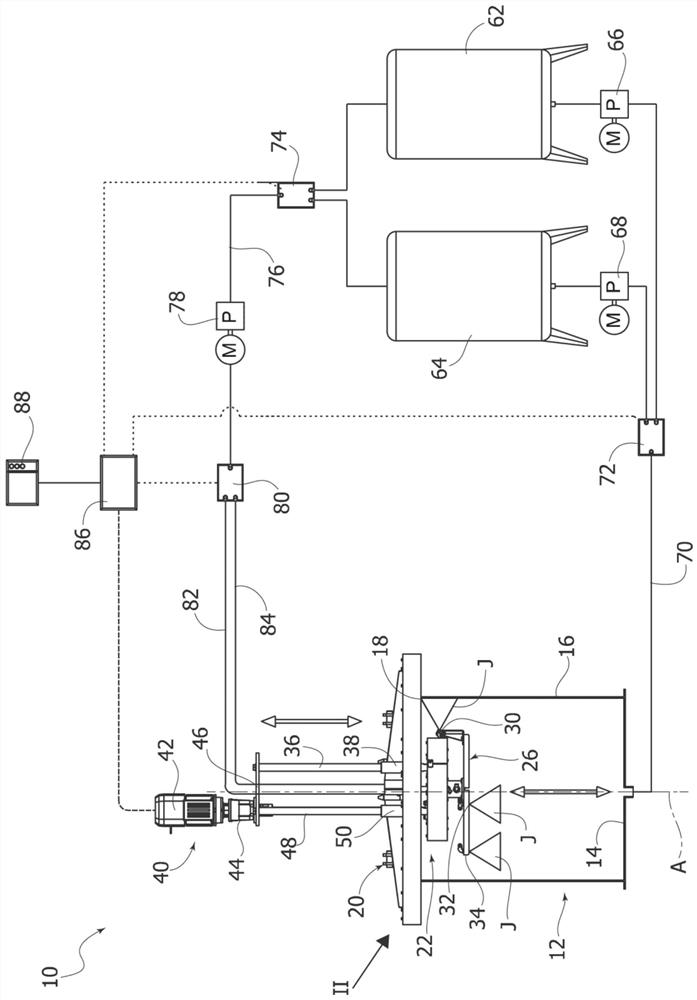

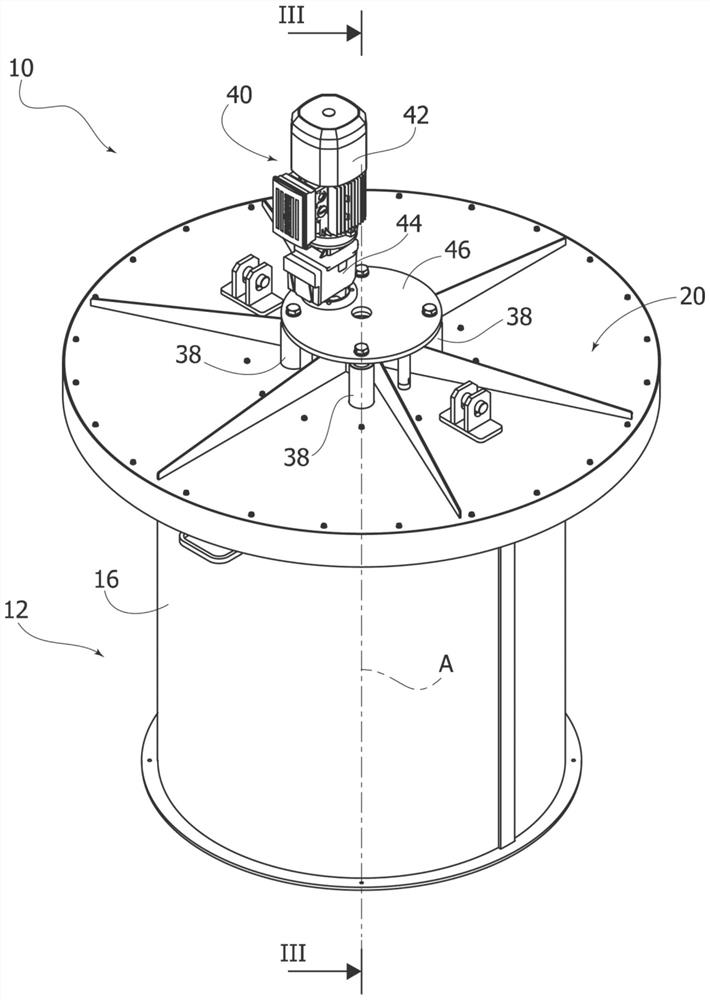

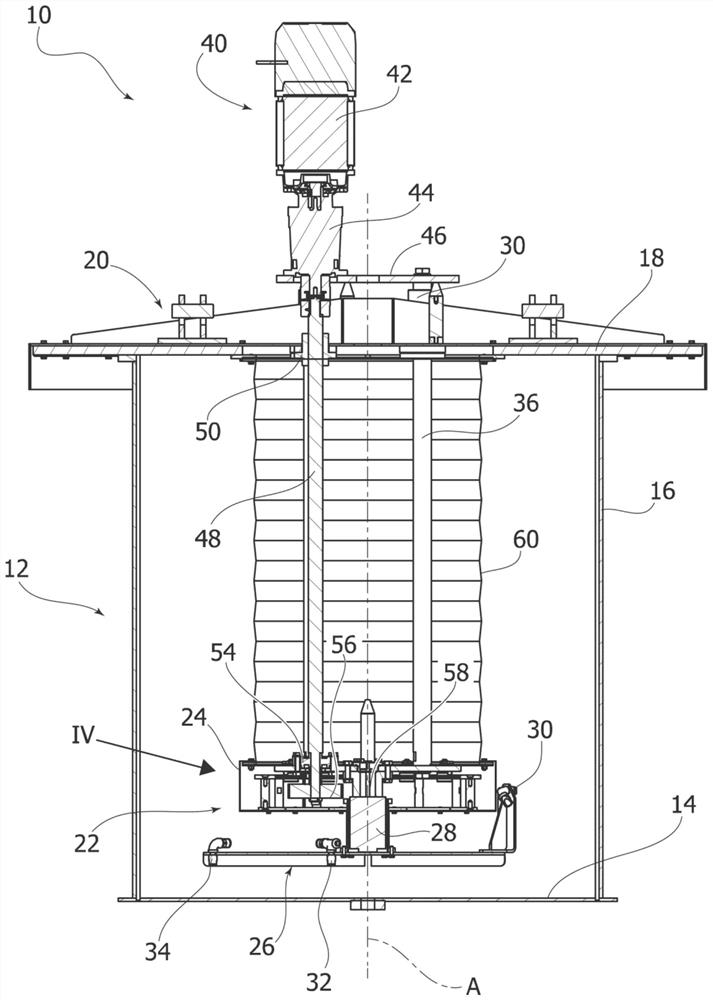

[0029] Referring to the drawings, numeral 10 denotes an apparatus for washing the container 12 . The apparatus 10 is configured to perform washing of large stainless steel vessels used as process tanks in machines or installations for the preparation of paints, dyes and the like. Each container 12 has a horizontal bottom wall 14 , cylindrical side walls 16 and an open upper edge 18 .

[0030] The device 10 comprises a support 20 having a substantially disc-shaped plate shape. During use, such as figure 1 , figure 2 with image 3 As shown, the support 20 is placed as a cover on the upper edge 18 of the container 12 .

[0031] The device 10 comprises a translation unit 22 which is movable relative to the support 20 along the vertical axis A. Figure 5 The raised position shown and Figure 6 Move between the lowered positions shown.

[0032] special reference image 3 with Figure 4 , the translation unit 22 includes a shell 24 that is hollow inside. The translation un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com