Punching equipment for continuous production of disc brushes

A technology of punching equipment and disk brushes, which is applied to cleaning methods and appliances, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of non-continuous processing and general punching efficiency, and achieve high punching efficiency , Improve the quality of punching and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

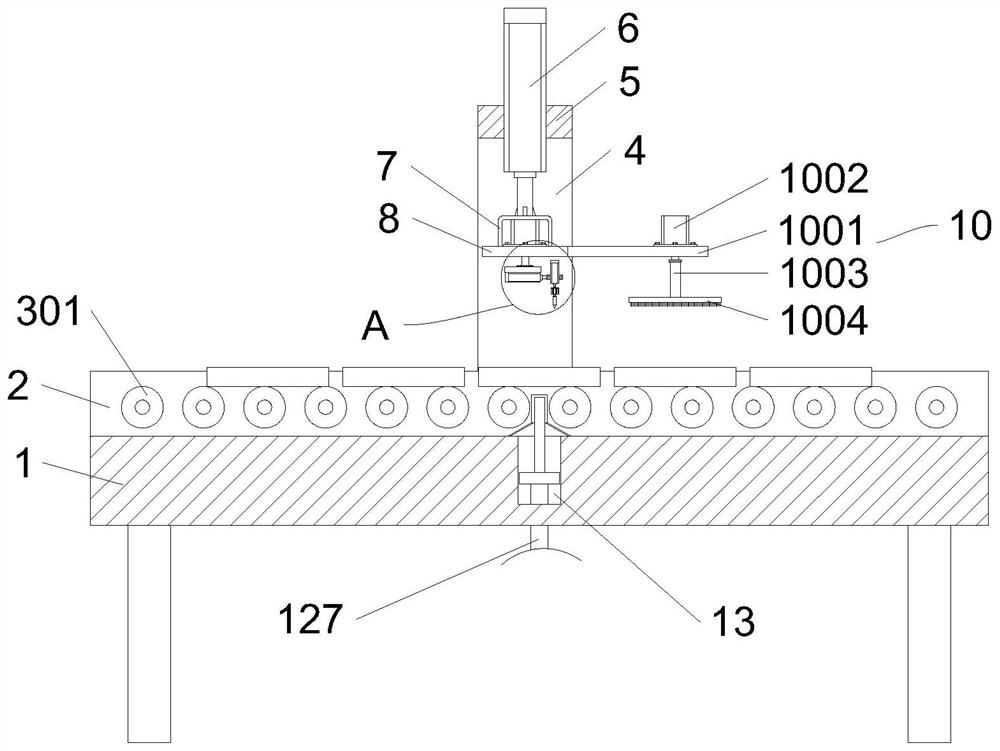

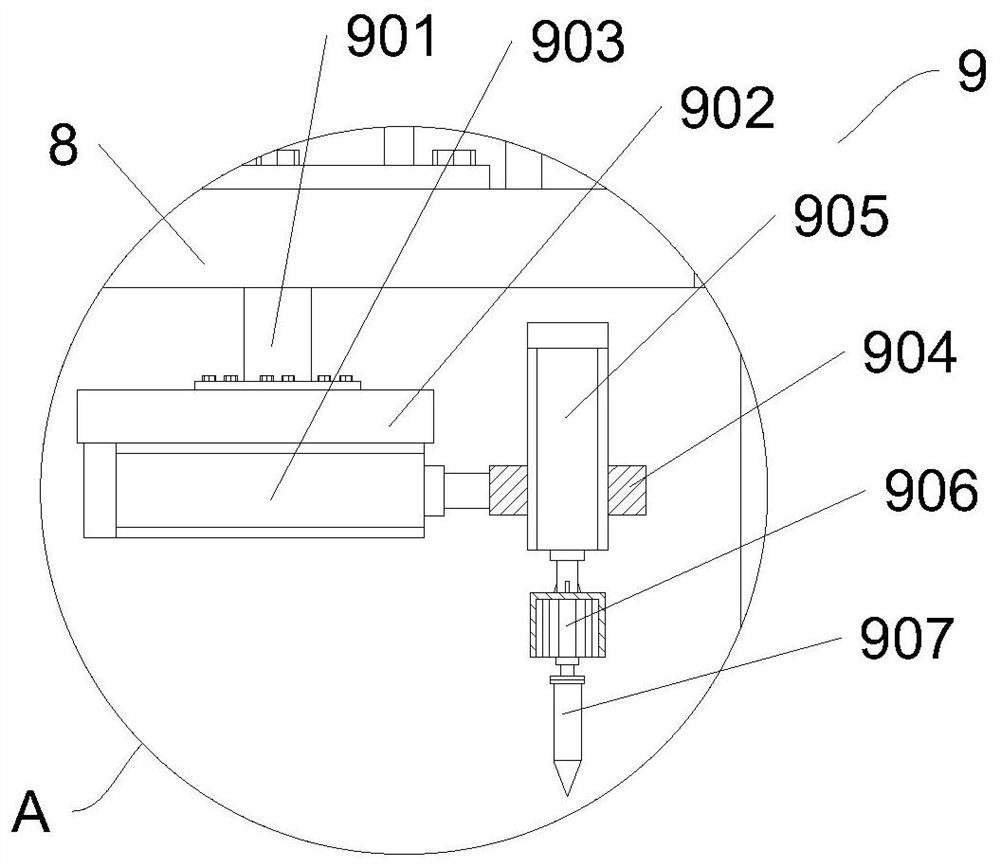

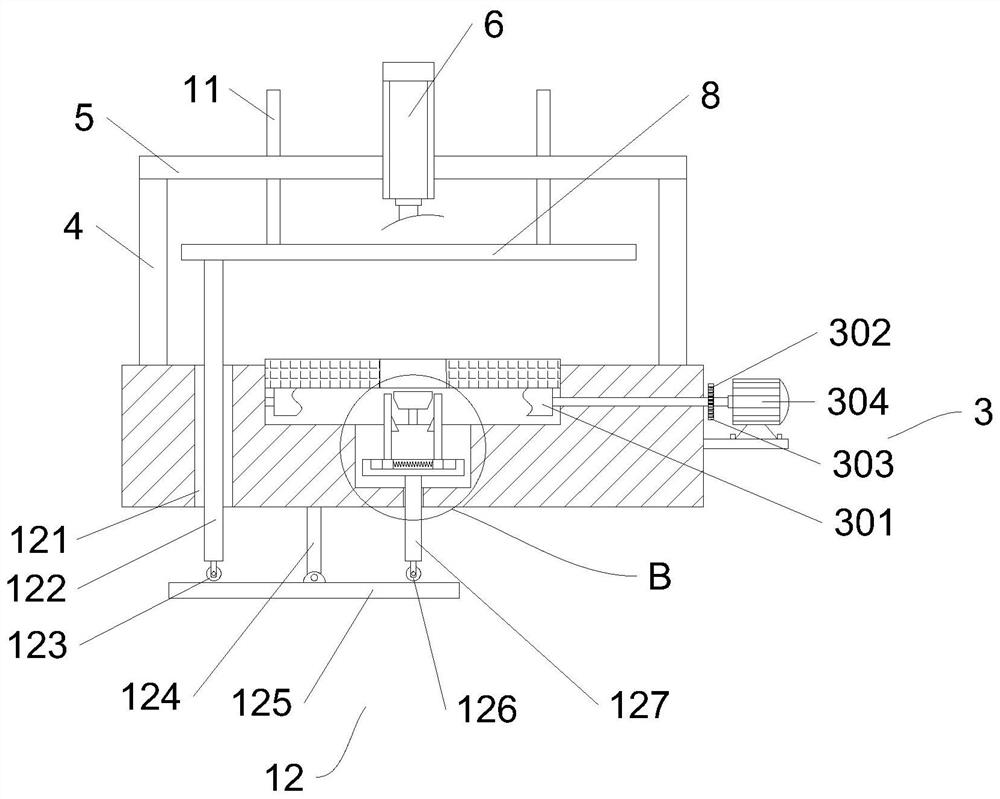

[0031] In this embodiment, as shown in Figure 1-6, a kind of punching equipment for the continuous production of disk brushes includes a workbench 1, and the top of the workbench 1 is provided with a through groove 2 along the horizontal direction, and a useful hole is installed in the through groove 2. The conveying mechanism 3 is used to convey the brush, and the top middle of the workbench 1 corresponds to the front and rear sides of the through groove 2. A horizontal plate 5 is fixed through the vertical plate 4. The middle part of the horizontal plate 5 is fixed with a hydraulic rod 6. The hydraulic rod The telescoping end of a 6 is fixed with a moving plate 8 through the support frame 7, and the top of the moving plate 8 is symmetrically fixed with a limit rod 11 along the front and rear directions. A drilling mechanism 9 for punching the disk brush is provided, and one end of the moving plate 8 along the conveying direction of the conveying mechanism 3 is provided with a...

Embodiment 2

[0034]On the basis of Embodiment 1, the cleaning mechanism 10 includes a support rod 1001 fixed to one end of the moving plate 8 along the conveying direction of the conveying mechanism 3, and the upper position of the support rod 1001 corresponding to the through groove 2 is fixed with a motor four 1002, and a motor four 1002 A rotating shaft 1003 is fixed at the output end of the rotating shaft 1003, and a cleaning brush 1004 is fixed at the bottom of the rotating shaft 1003. The bristle of cleaning brush 1004 adopts wear-resistant plastic material. Through the above method, during the downward movement of the moving plate 8, the cleaning brush 1004 is driven to move down to the surface of the disc brush, the motor 4 1002 is started, the rotating shaft 1003 and the cleaning brush 1004 are driven to rotate, and the waste debris generated by punching is cleaned to avoid waste debris. Accumulated on the surface of the disc brush, it is convenient for the subsequent processing o...

Embodiment 3

[0036] On the basis of Embodiment 2, the transmission mechanism 12 includes a through hole 121 that runs through the workbench 1 and is located at the rear side of the through groove 2, and the bottom end of the moving plate 8 corresponds to the position of the through hole 121 and is vertically fixed with a transmission rod. One 122, the bottom end of the transmission rod one 122 passes through the through hole 121 and is correspondingly abutted against the rotating rod 125 arranged along the front and rear direction, the top middle part of the rotating rod 125 is rotationally connected with the fixed rod 124, and the top of the fixed rod 124 is connected with the workbench The bottom end of 1 is fixed, and the position of the front section of the top of the rotating rod 125 corresponds to the position of the groove 13. The transmission rod 2 127 with a rectangular cross section is correspondingly abutted. The top of the transmission rod 127 is slidably connected with the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com