Fabricated wallboard, continuous fabricated wallboard and continuous production process

A prefabricated and wall panel technology, applied in the direction of manufacturing tools, structural elements, building components, etc., can solve the problems of complex manufacturing process and inability to realize the production of prefabricated wall panels, achieve strong grip, save positioning links, Good bending and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Assembled wall panel

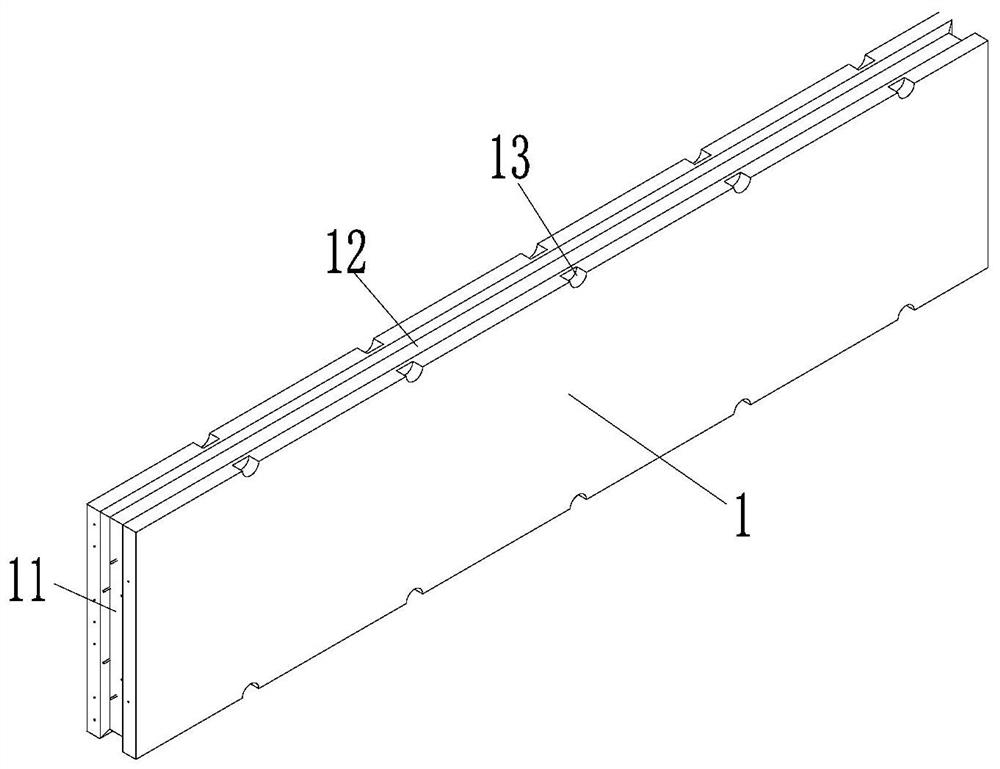

[0046] Such as Figure 1-14 As shown, the assembled wallboard, including wallboard 1, includes the thickness direction, width direction and length direction, wherein the two faces corresponding to the thickness direction are the front and rear planes, the two faces corresponding to the width direction are the left and right facades, and the length direction The corresponding two faces are upper and lower end faces.

[0047] The wall panel 1 is made of ordinary concrete, lightweight concrete, foamed concrete or high-strength gypsum.

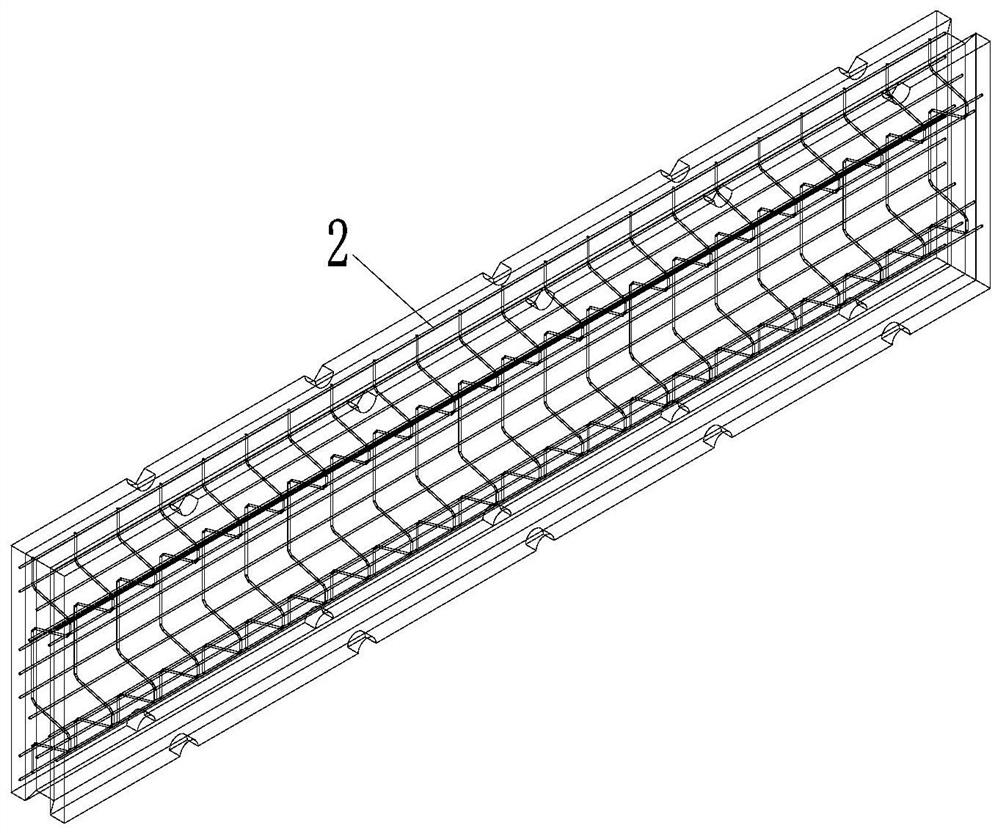

[0048] Different from the wallboard 1 in the prior art, a steel mesh 2 is embedded in the wallboard 1 of this embodiment, and the steel mesh 2 is formed by vertically fixing several transverse ribs 21 and several longitudinal ribs 22, wherein The longitudinal ribs 22 along the length direction of the wallboard 1 and the transverse ribs 21 along the width direction of the wallboard 1 . The longitudinal ...

Embodiment 2

[0054] Embodiment 2 Continuous assembled wallboard

[0055] The continuous prefabricated wallboard includes the prefabricated wallboard of Embodiment 1, and the steel mesh sheet 2 extends to both ends of the wallboard 1 in the length direction.

[0056] In other words, it is formed by cutting the prefabricated wallboard of Example 1 of indefinite length (infinite length) through continuous production. Since the reinforced mesh sheet 2 of the assembled wallboard of indefinite length is also infinitely long along the length direction, the ends of the reinforced mesh sheet 2 are flush with the upper and lower end faces of the wallboard 1 after cutting.

[0057] Continuous production process of continuous fabricated wall panels:

[0058] 1. Bending: Take the steel mesh and bend it into a wavy structure;

[0059] 3. Pouring: pouring the wallboard material, and the steel mesh is embedded in it;

[0060] 3. Forming: the wall panel is limited to the required shape through the surro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com