Galvanized strip steel conveying deviation rectifying device

A deviation correction device and strip technology, which are applied in transportation and packaging, coiling strips, thin material handling, etc., can solve the problems of strip steel wear of carrying machinery, deviation of strip running center, and uneven strip coiling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

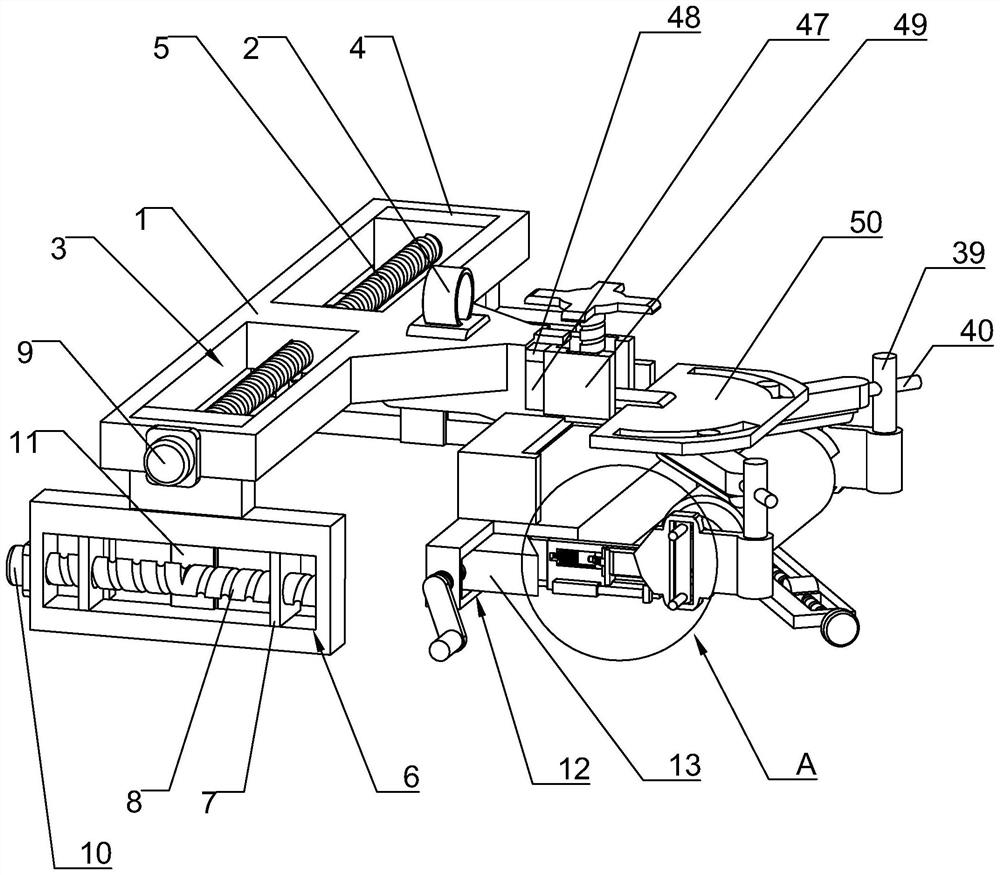

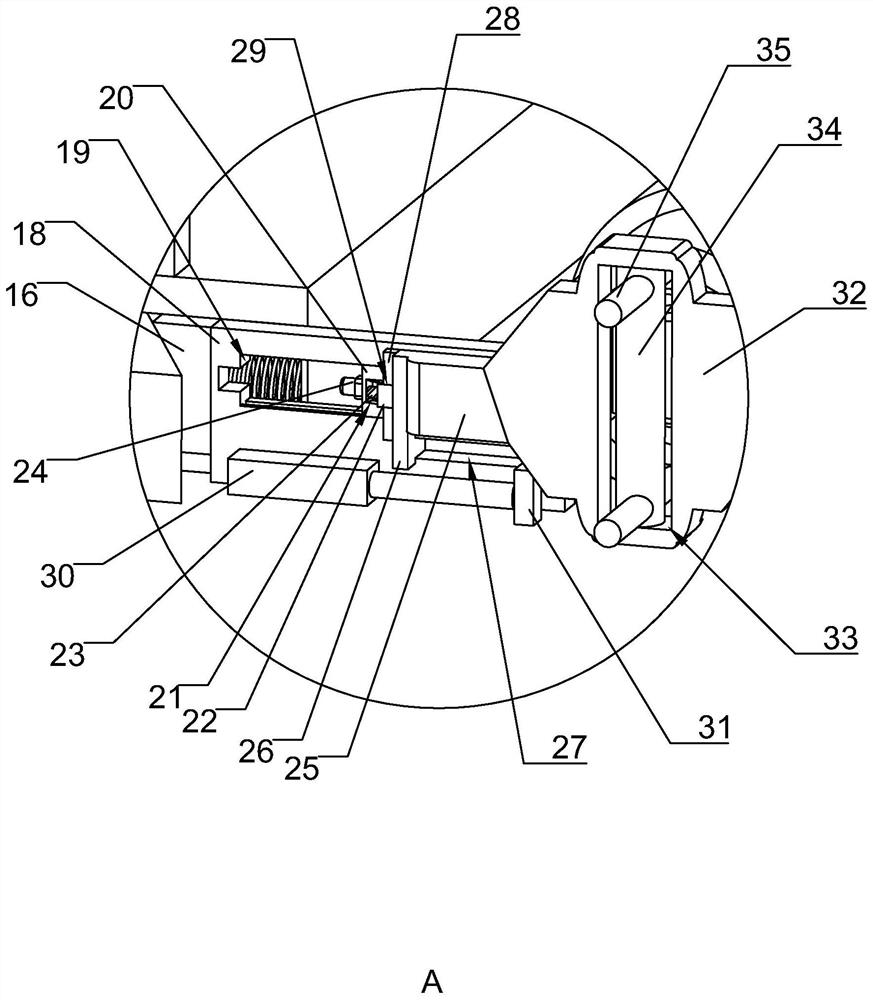

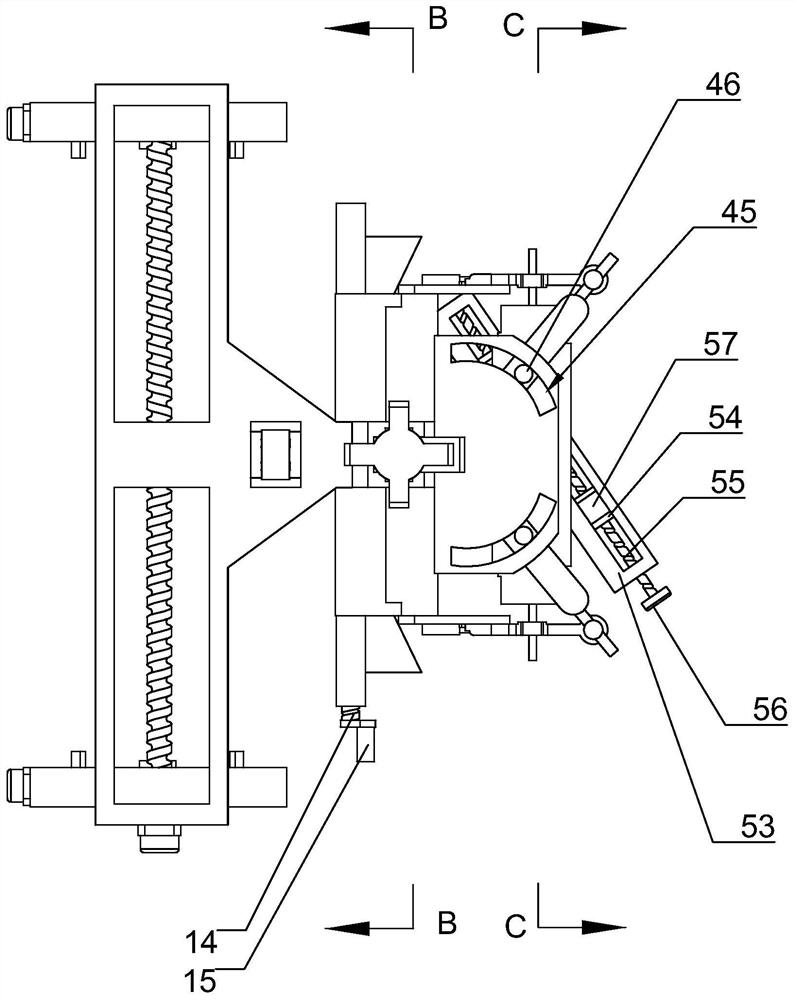

[0036] refer to figure 1 , is a galvanized strip transmission correction device disclosed in the present invention, which includes a working board 1 and a suspension ring 2 fixed on its upper surface. The working board 1 is provided with a locking assembly for locking the position of the working board 1. The locking assembly includes an opening In the clamping groove 3 on the lower surface of the working plate 1, two clamping plates 4 are slidably arranged in the clamping groove 3, and the two clamping plates 4 are respectively threaded on both ends of a clamping double-threaded screw 5 , the clamping double-thread screw rod 5 is rotatably arranged in the clamping groove 3 and driven by the clamping motor 9 fixed on the working plate 1 . The clamping plate 4 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com