Microbial fermentation equipment for sludge treatment

A technology of microbial fermentation and sludge treatment, applied in biological sludge treatment, mixer, dissolution, etc., can solve the problems of high flow speed, consumption of oxygen, decreased oxygen effect, etc., to improve the blocking effect, improve the comprehensiveness, The effect of increasing the duration of contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

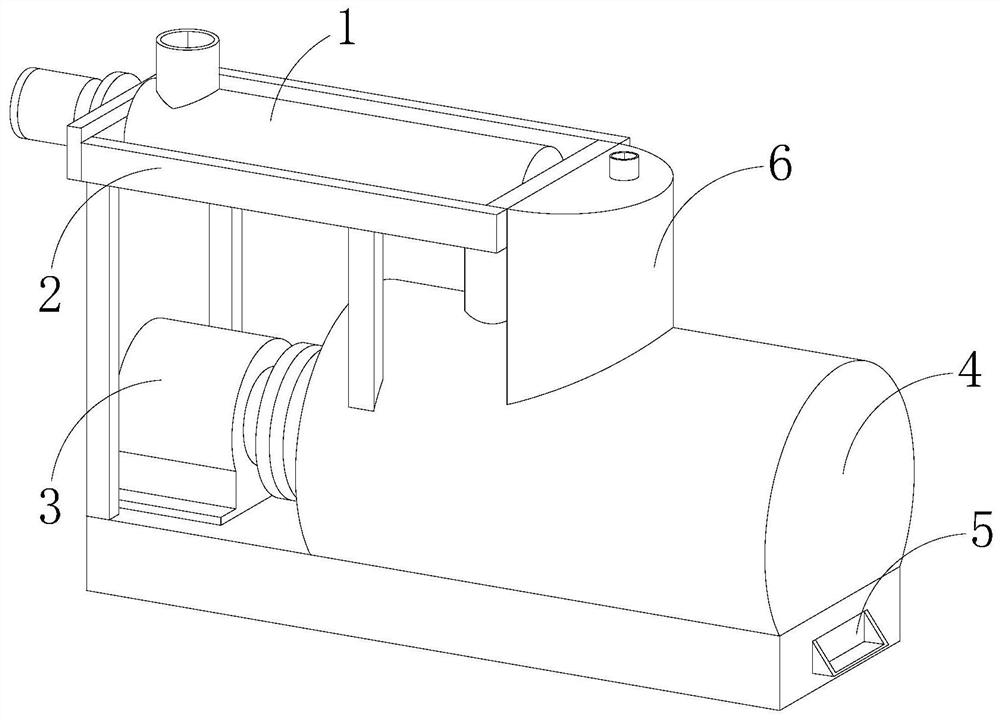

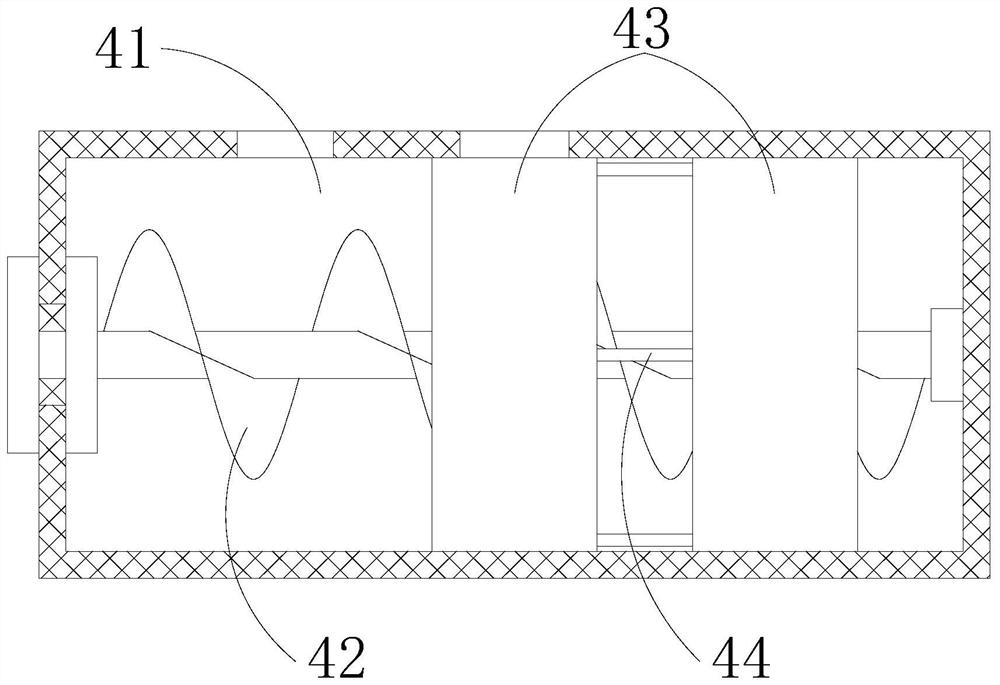

[0022] as attached figure 1 to the attached Figure 5 shown:

[0023] The present invention is a microbial fermentation equipment for sludge treatment. Its structure includes a feed pipe 1, a support frame 2, a motor 3, a fermentation device 4, a discharge port 5 and a ventilation chamber 6. 2 top, and the lower end of the support frame 2 is welded with the top of the fermentation device 4, the output end of the motor 3 rotates synchronously with the inside of the fermentation device 4, the lower right end of the fermentation device 4 is embedded with a discharge port 5, and the ventilation chamber 6 is on the upper left The end is welded with the right end of the support frame 2, and the lower end of the ventilation chamber 6 is installed on the middle end of the top of the fermentation device 4 and communicates with each other. Through the pipe 44, a screw agitator 42 is installed at the inner middle end of the fermentation tank 41, and the screw agitator 42 rotates synchr...

Embodiment 2

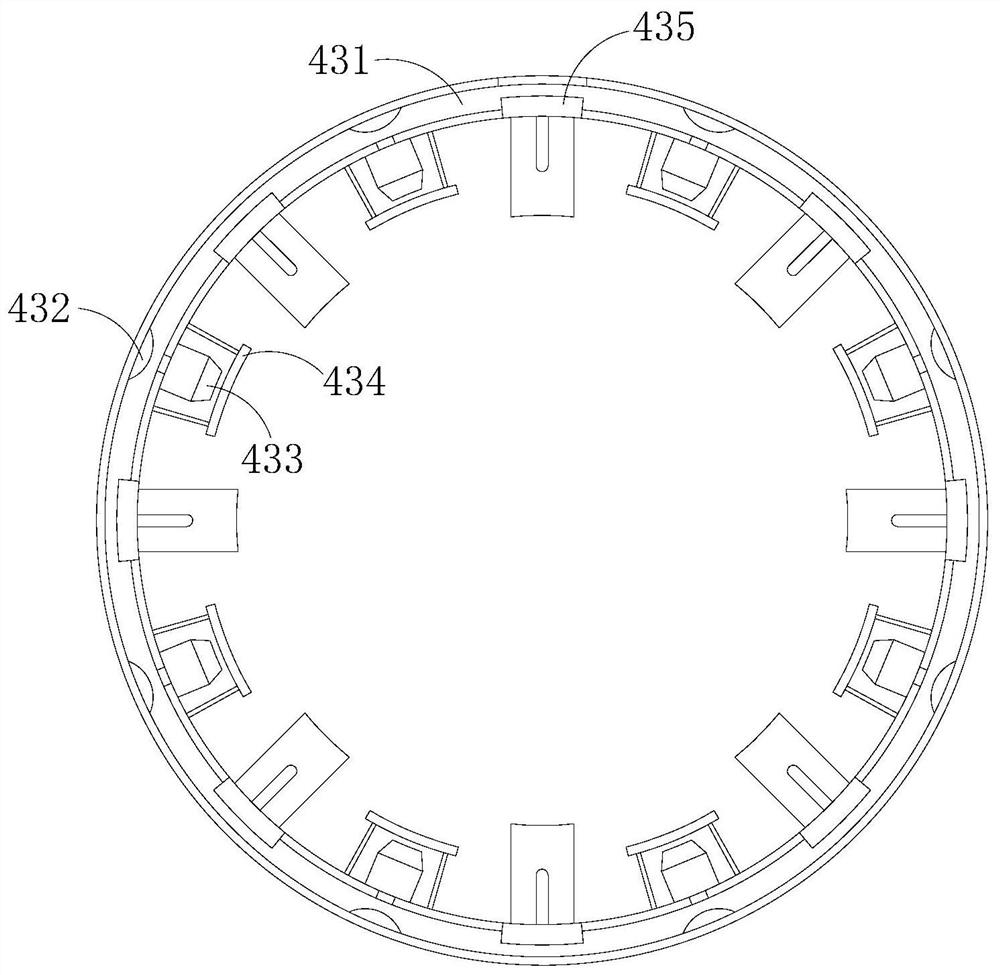

[0030] as attached Image 6 to the attached Figure 7 shown:

[0031] The swing mechanism 435 includes a rotating shaft 35a, a guide rod 35b, and a baffle plate 35c. The rotating shaft 35a is provided inside the ventilation plate 431, and the rotating shaft 35a is installed on the upper end of the baffle plate 35c. The guide rod 35b The upper end is fixed to the inner side wall of the ventilation plate 431, and the lower end of the guide rod 35b passes through the inner middle end of the baffle plate 35c by clearance fit. 35c has the effect of blocking the flow of the sludge during the stirring process, thereby improving the fermentation time of the sludge.

[0032] The baffle plate 35c includes a plate body c1 and a partition plate c2. The upper end of the plate body c1 is provided with a rotating shaft 35a, and the plate body c1 is located on the inner side wall of the ventilation plate 431. The partition c2, the partition c2 is installed inside the plate body c1 at an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com