Vertical ejection scaling test device constructed based on high-pressure air

A high-pressure air, scaling test technology, used in aerodynamic tests, machine/structural component testing, measuring devices, etc. Test comparison and verification and other issues to achieve the effect of reducing impact, improving economy and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

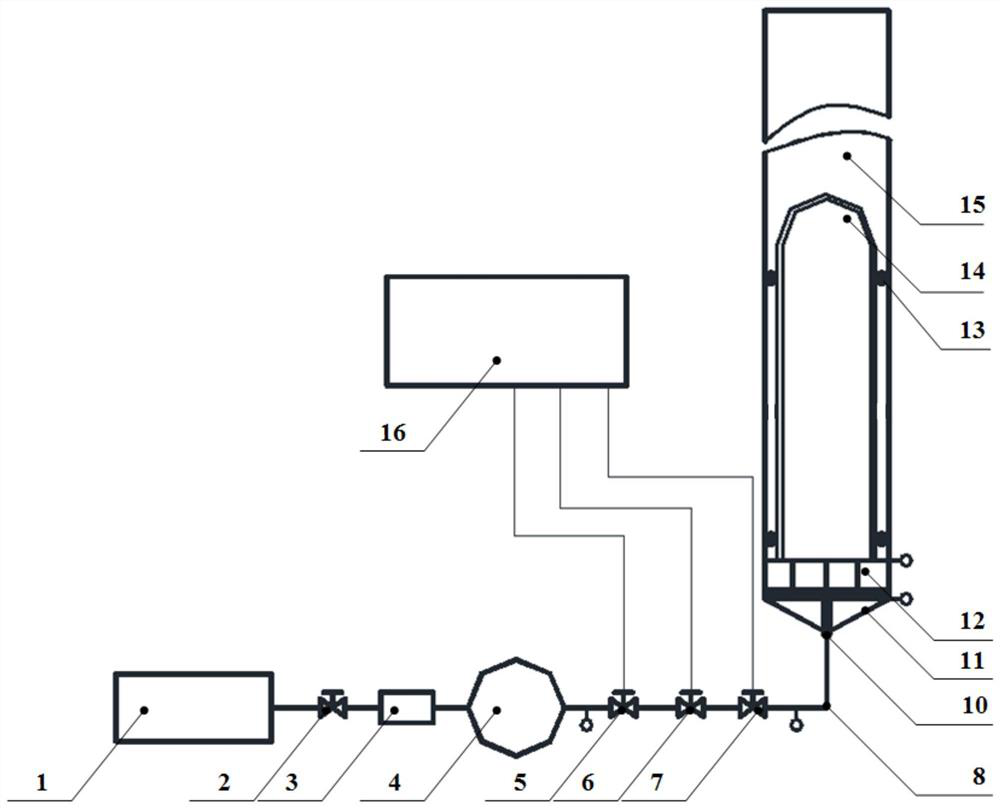

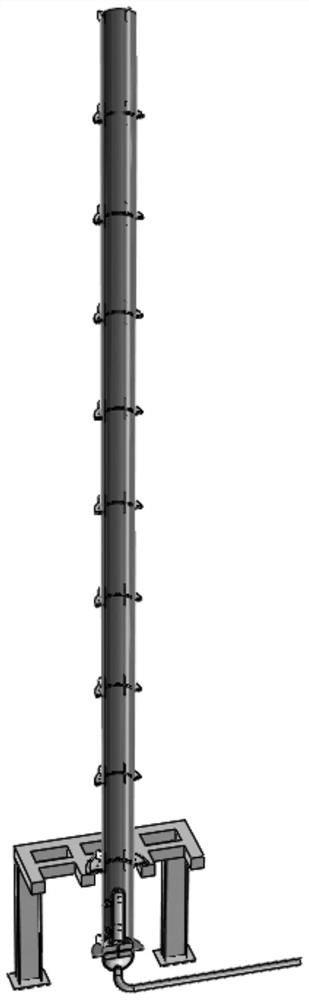

[0020] A vertical ejection scaling test device based on high-pressure air, such as figure 1 , figure 2 As shown, the test device includes: air compressor 1, inflation valve 2, dryer 3, high-pressure gas tank 4, stop valve 5, quick valve 6, regulating valve 7, piping system 8, bracket 9, breaking rod 10, Intake head 11, piston 12, guide wheel 13, projectile 14, launch tube 15 and measurement and control system 16.

[0021] The cut-off valve 5 is connected to the high-pressure gas tank 5 through a pipeline, the quick valve 6 is located at the downstream of the shut-off valve 5, and is connected with the shut-off valve 6 through a pipeline, and the regulating valve 7 is located at the downstream of the quick valve 6, and is connected to the ejection system through a pipeline;

[0022] The cut-off valve 5 adopts an electric ball valve, and the full opening and closing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com