nested scanning probe microscope

A scanning probe and microscope technology, applied in the field of scanning probe microscopy, can solve the problem of large space occupation in the stepping direction of the motor, and achieve the effects of reducing thermal drift, compact structure and high space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

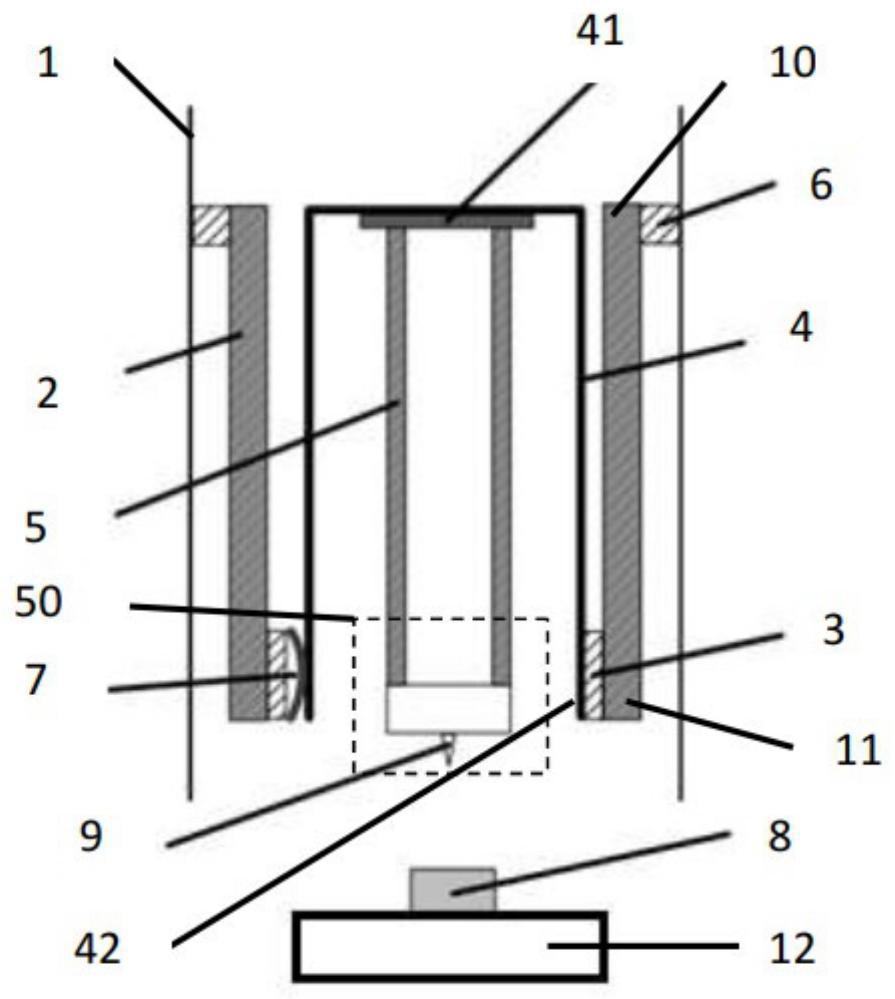

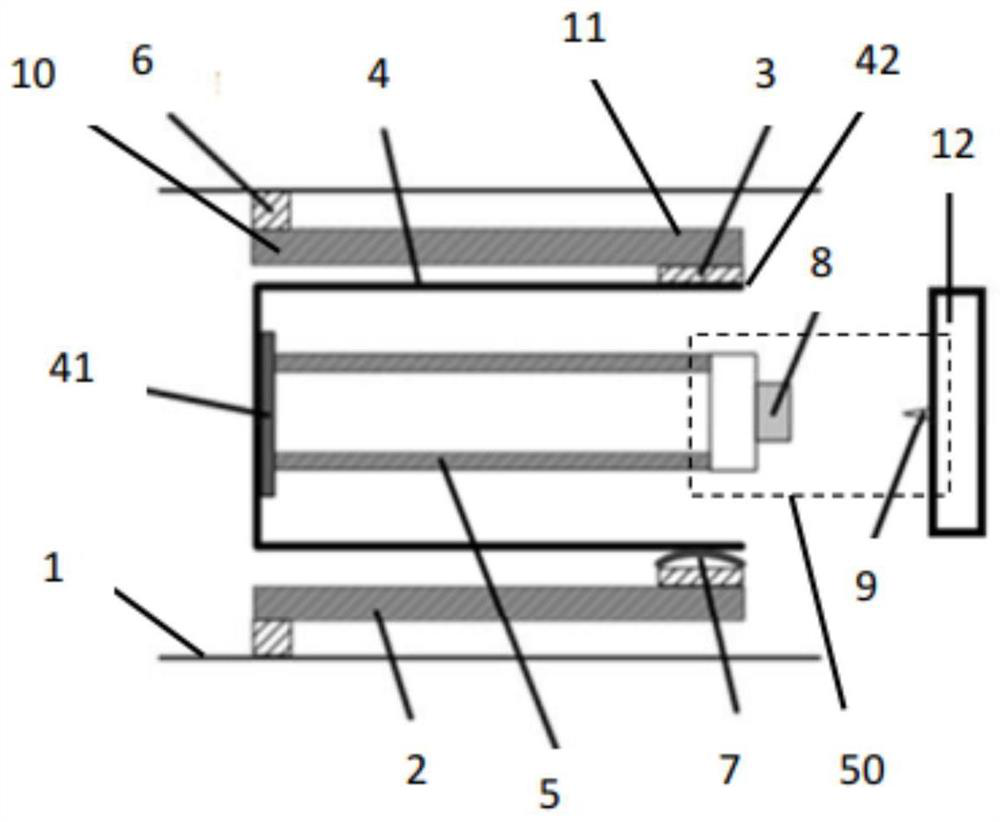

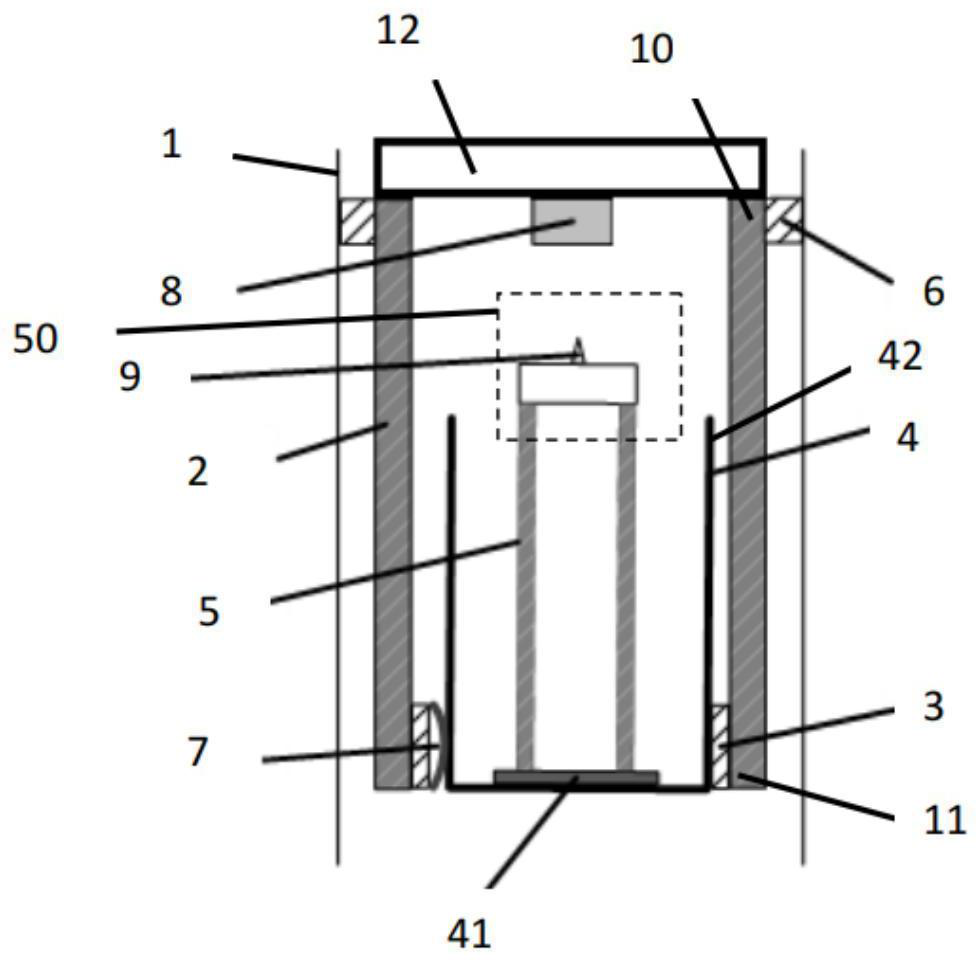

[0024] The technical solutions provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 Shown is the first embodiment, the nested scanning probe microscope includes a housing 1, and also includes a stepping motor, an insulating tube 3, an insulating weight frame 4 and a scanning head that are sequentially sleeved coaxially along an axial direction. 5.

[0026] The stepper motor is a piezoelectric tube 2, the piezoelectric tube 2 is a hollow tubular structure, the piezoelectric tube 2 has a fixed end 10 and a free end 11 opposite to each other, and the insulating tube 3 wraps around the The axial direction is circumferentially arranged on the inner wall of the free end 11 , and the outer wall of the fixed end 10 is bonded and fixed on the housing 1 through the fixing block 6 .

[0027] The insulating tube 3 is glued and fixed on the free end 11; an elastic member 7 is arranged between the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com