Defective battery screening method, equipment and medium based on machine learning

A technology of machine learning and screening methods, applied to instruments, measuring electricity, measuring electrical variables, etc., can solve problems such as poor battery quality, battery misjudgment, low yield rate, etc., to improve product circulation efficiency, reduce inventory pressure, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

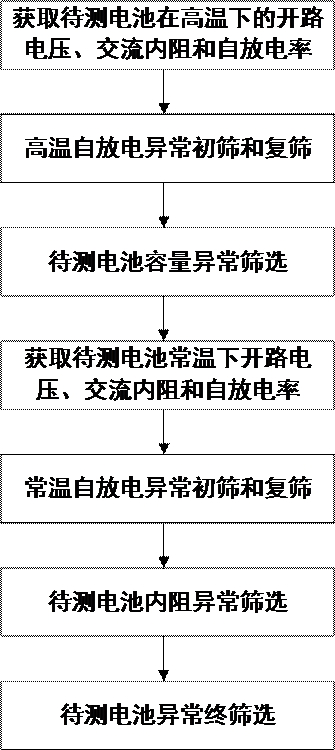

[0042] Embodiment 1 of the present invention provides a method for screening defective batteries based on machine learning.

[0043]First, set the batch test samples. In this example, 15,000 batteries on the battery production line are selected as the battery samples to be tested; Screening detection, the detection sequence can be adjusted according to the actual situation.

[0044] In the production process of the battery assembly line, after obtaining the data of n batteries, a sliding mechanism is used for screening and detection. For the sample data group of data, whenever new battery sample data is obtained, the battery sample data obtained first in the sample data group will be replaced to form a new sample data group. Detect the data in the sample data group, and judge the result of the latest data in the sample data group; that is, in the battery assembly line production process, after obtaining the sample data of adjacent n batteries, according to the 1~n battery sam...

Embodiment 2

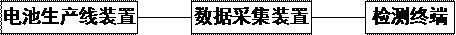

[0060] Embodiment 2 of the present invention provides a defective battery screening device, such as figure 2 As shown, including detection terminal, data acquisition device, battery production line device;

[0061] The detection terminal is used to detect defective batteries and normal batteries of the battery samples produced in the battery production line device and output the results;

[0062] The data acquisition device is used to collect the parameter data of the battery sample to be tested in the battery production line device and transmit the data to the detection terminal;

[0063] The battery production line device is used to produce batteries and provide a temperature environment for battery testing.

Embodiment 3

[0065] Embodiment 3 of the present invention provides a computer storage medium, which stores a computer program, and when the computer program is executed by a processor, the steps of the above method for screening defective batteries based on machine learning are implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com