Arc-shaped laminated lithium battery and lamination method thereof

A lithium battery and arc technology, which is applied in the field of arc laminated lithium batteries and their laminations, can solve the problems of difficulty in controlling the flatness of laminations, hidden dangers of battery safety, and short circuits of batteries, so as to improve stability and safety, Improved performance, improved flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

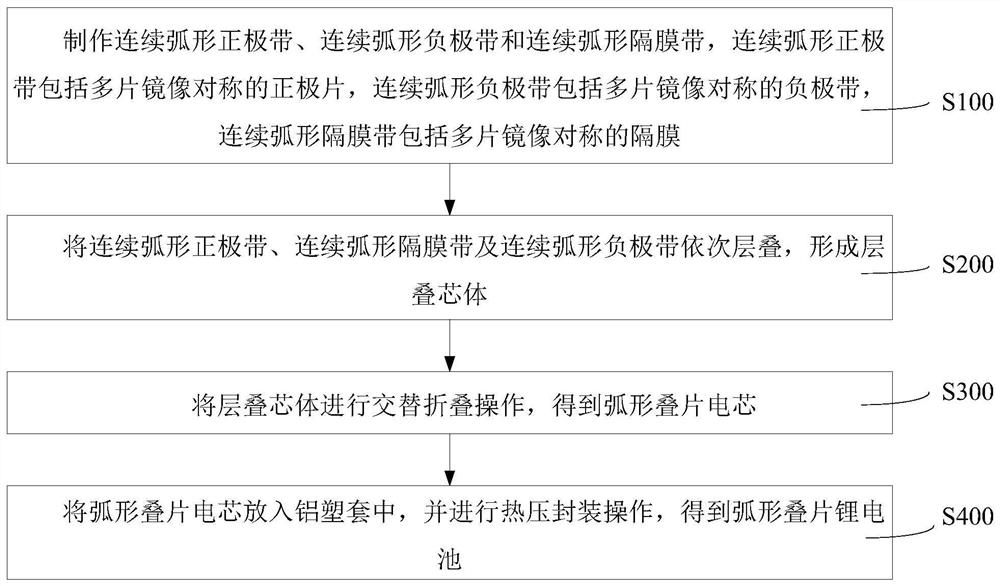

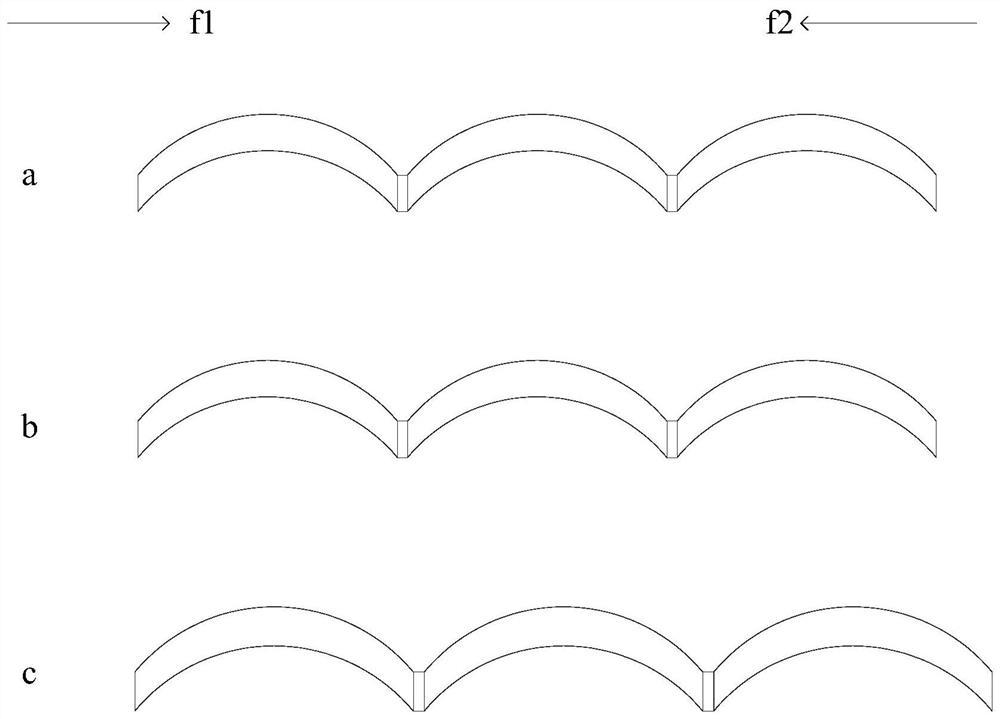

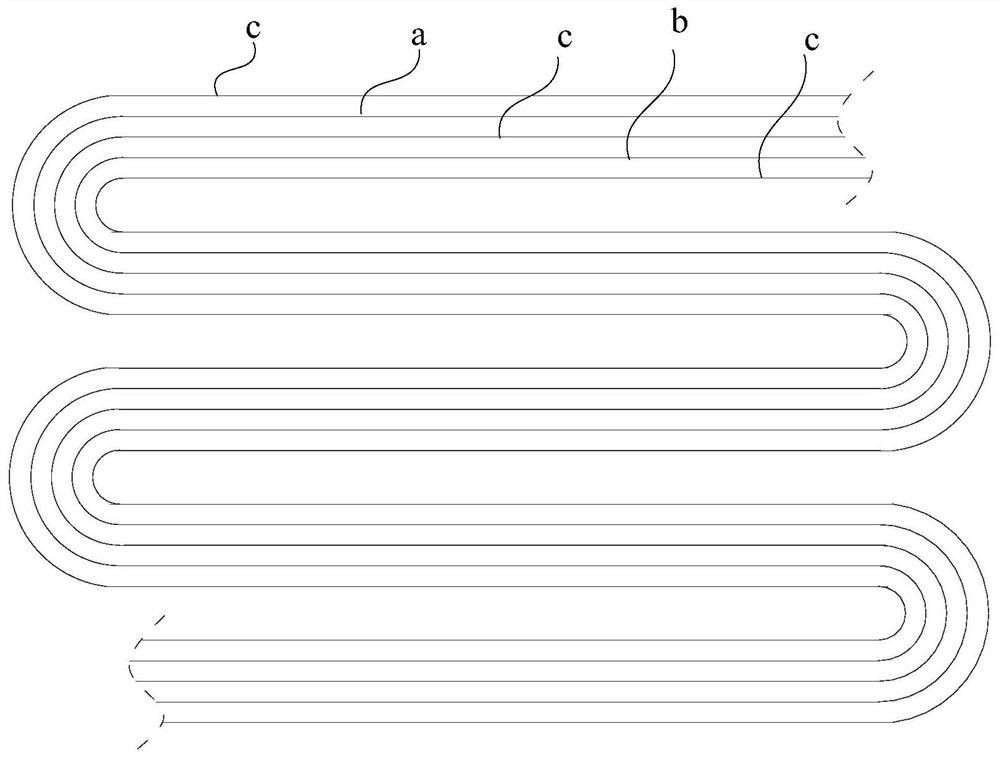

[0059] Make continuous arc positive electrode strips, continuous arc negative electrode strips and continuous arc diaphragm strips. The continuous arc positive electrode strips include multiple mirror-symmetrical positive electrode sheets, and the continuous arc-shaped negative electrode strips include multiple mirror-image symmetrical negative electrode strips. The continuous arc-shaped The membrane strip includes a plurality of mirror-symmetrical membranes. A hot-melt adhesive coating operation is performed on the diaphragm, and the continuous arc-shaped positive electrode strip, the continuous arc-shaped diaphragm strip with a hot-melt adhesive coating layer, and the continuous arc-shaped negative electrode strip are sequentially stacked to form a laminated core. A baking operation was performed on the laminated core body, wherein the baking temperature was 120°C. The laminated core is alternately folded, and then the folded laminated chip is placed in an aluminum-plastic s...

Embodiment 2

[0061] Make continuous arc positive electrode strips, continuous arc negative electrode strips and continuous arc diaphragm strips. The continuous arc positive electrode strips include multiple mirror-symmetrical positive electrode sheets, and the continuous arc-shaped negative electrode strips include multiple mirror-image symmetrical negative electrode strips. The continuous arc-shaped The membrane strip includes a plurality of mirror-symmetrical membranes. A hot-melt adhesive coating operation is performed on the diaphragm, and the continuous arc-shaped positive electrode strip, the continuous arc-shaped diaphragm strip with a hot-melt adhesive coating layer, and the continuous arc-shaped negative electrode strip are sequentially stacked to form a laminated core. A baking operation was performed on the laminated core body, wherein the baking temperature was 140°C. The laminated core is alternately folded, and then the folded laminated chip is placed in an aluminum-plastic s...

Embodiment 3

[0063] Make continuous arc positive electrode strips, continuous arc negative electrode strips and continuous arc diaphragm strips. The continuous arc positive electrode strips include multiple mirror-symmetrical positive electrode sheets, and the continuous arc-shaped negative electrode strips include multiple mirror-image symmetrical negative electrode strips. The continuous arc-shaped The membrane strip includes a plurality of mirror-symmetrical membranes. A hot-melt adhesive coating operation is performed on the diaphragm, and the continuous arc-shaped positive electrode strip, the continuous arc-shaped diaphragm strip with a hot-melt adhesive coating layer, and the continuous arc-shaped negative electrode strip are sequentially stacked to form a laminated core. A baking operation was performed on the laminated core body, wherein the baking temperature was 130°C. The laminated core is alternately folded, and then the folded laminated chip is placed in an aluminum-plastic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com