Liquid injection mechanism with humidity control structure for automatic production of lithium battery

A humidity control, lithium battery technology, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of inconvenient use, inflexible use, inconvenient lithium battery transmission rate, etc., to save space and limit convenience Bit-fixed, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

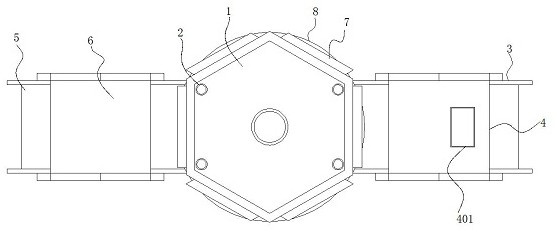

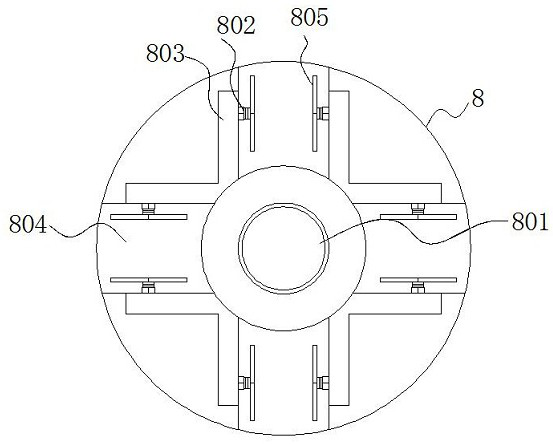

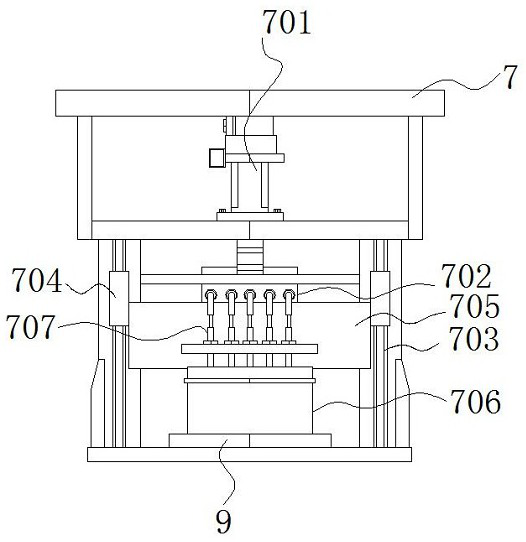

[0051] see figure 1 with Image 6, the present invention provides a technical solution: a liquid injection mechanism with a humidity control structure for automatic production of lithium batteries, comprising: a main body 1; There are four, and the support column 2 and the main body 1 are an integrated structure, and the liquid injection assembly 7 is distributed in a ring shape with respect to the center of the main body 1, and the design of the support column 2 can make the entire main body 1 be installed in the desired fixed position. Plane, so that the main body 1 can be placed without grounding, providing space for the placement of subsequent transmission components. The design of the stacked structure between each component unit effectively saves the space occupied by the liquid injection mechanism, and is convenient for placement in some places where the space is not large enough. The main body The right end of the outside of 1 is equipped with a first conveyor belt 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com