A mine conveyor with a detachable anti-skid belt

A conveying device and anti-slip technology, which can be used in conveyors, transportation and packaging to solve the problems of mineral material slippage, restricting mining efficiency, and reducing belt contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

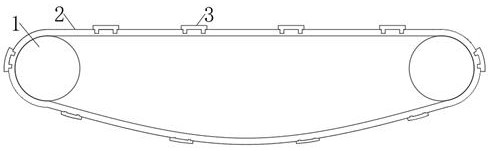

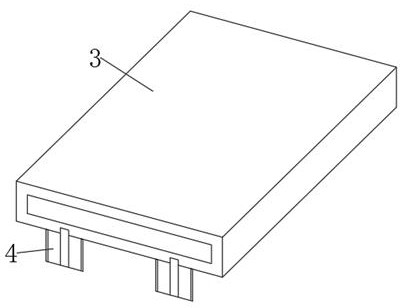

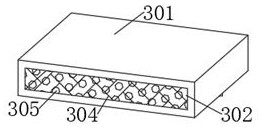

[0041] see Figure 1-5 and Figure 9 , a mine conveying device with a detachable anti-skid belt, including a pair of conveying rollers 1 and a conveying belt 2 matched with each other, the conveying belt 2 is sleeved on the outside of the two conveying rollers 1, and the conveying belt 2 is connected with multiple An anti-skid belt 3, two pairs of fixed feet 4 are fixedly connected on the side wall of the anti-skid belt 3, the interference fit between the conveyor belt 2 and the fixed feet 4, the anti-skid belt 3 is realized with the conveyor belt through two pairs of fixed feet 4 2, the anti-skid belt 3 includes a wear-resistant rubber block 301, and a deformation chamber 302 is excavated in the wear-resistant rubber block 301, and the deformation chamber 302 is filled with a plurality of skeleton fibers 304 and high-strength filling balls 305, and a plurality of skeleton fibers 304 are all in the shape of straight rods, and adjacent skeleton fibers 304 overlap each other to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com